4-- 14© 2012 Mobile Climate Control T-299 Rev. 08/2012

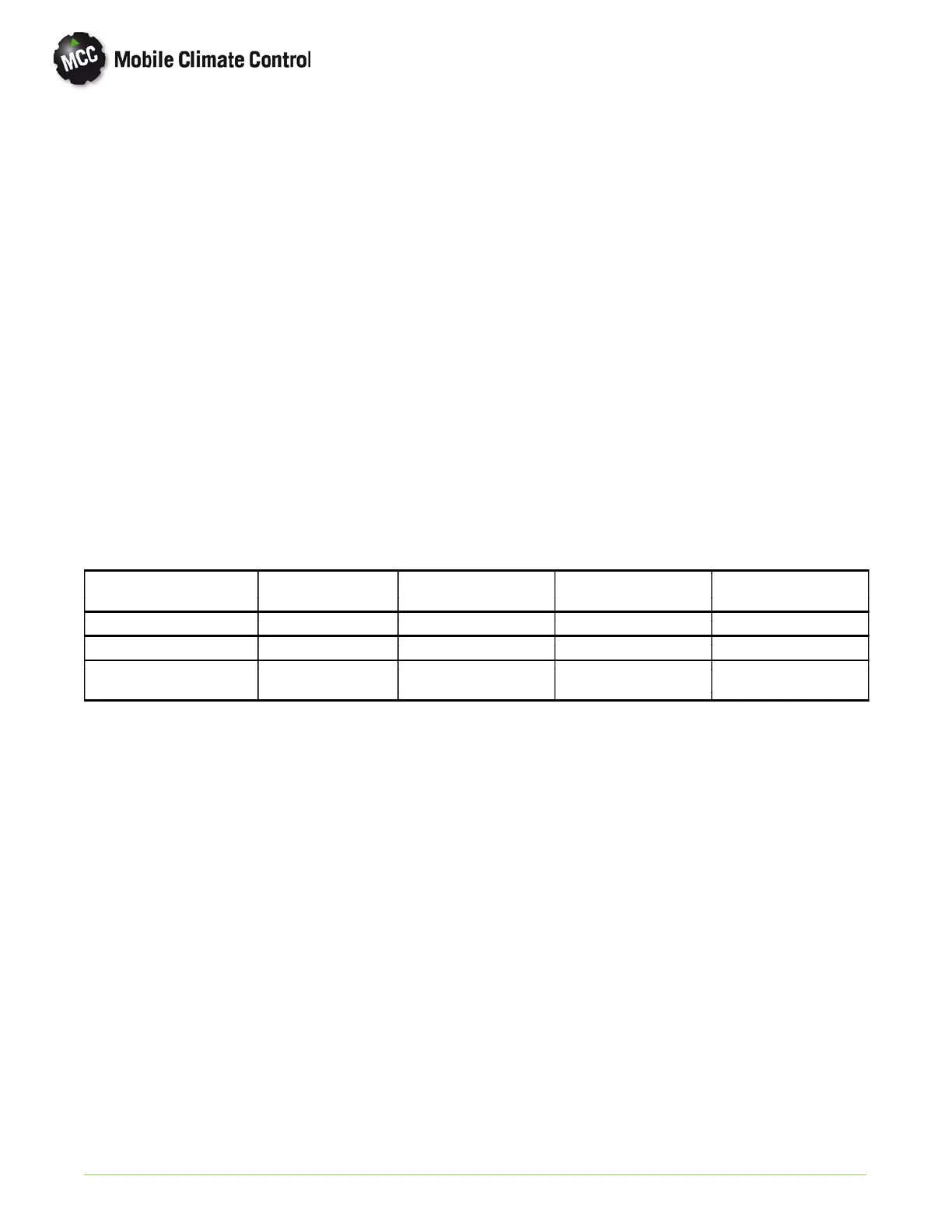

Notice that new belt tension is higher than in-service

or re-tension amount. All new belts require a run-in

period. During this period, a new belt will stretch

more in a 10 hour run time than the entire life of the

belt. So it is important to recheck belt tension after

run-in or re-tension new belts if less than re-tension

amount prescribed above. You should check belt

tension with the belt ”hot.” However, the belt must

be allowed to cool before re-tensioning. Drives

which incorporate automatic tensioners do not

require a run-in period or re-tensioning.

4.12.5 Measuring Methods for Belt Tension

There are several methods and tools available for

determining belt t en sion. The industry's acceptable

method would be to use a belt tension gauge as

manufactured by Burroughs or approved equal.

There are also several models available than can be

used. Please follow manufacturer guidelines

regarding gauge selection operation and calibration

requirements. You must get the correct tension

gauge for your specific b elt type(s).

4.13 RETURN AIR FILTER

NOTE

Never operate the evaporator without the

return-air filter properly installed.

The evaporator return air filter(s) should be checked

for cleanliness periodically(refer to table 4.1) and

always with regard to operating conditions. A system

operating on unpaved dusty roads will need a stricter

maintenance schedule than a bus operating

consistently on paved roads. A dirty air filter will

restrict the air flow over the evaporator coil. This

could cause insufficient co o ling or heating and

possible frost build-up on the coil. The GEN 4 series

return air filters are secured to the rear of the

evaporator coil assembly, while the GEN 5 series

return air filters are located under the evaporator

cover assembly.

Table 4-9 Belt Tension Guide

Drive Belt Top Width

New Belt

Lbs. Tension

Re-Tension

Lbs. Tension

Re-Tension

Threshold

Alternator All 110 90 70

Compressor All 130 105 80

Poly-Rib Belt

& Serpentine Drive

6orMoreRibs 145 105 90

4.13.1 GEN 4 (EXCEL) Series

Replace the GEN 4 series return air filter(s) as

follows:

a. Remove the evaporator return air grill.

b. Remove the return air filter from behind the coil

assembly.

c. With the return air filter(s) and return air grill

removed, it is advisable to check the evaporator coil.

If the coil is dirty pro ceed with cleaning the coil.

d. Clean or replace the return air filter(s).

e. Replace evaporator return air grill.

4.13.2 GEN 5 Series

Replace the GEN 5 series return air filter(s) as

follows:

a. Insert a 3mm Allen wrench into the 1/4 turn

receptacle stud.

b. Turn counterclockwise opening the filter channel.

c. Slide filter out of the evaporator grill. (In some

applications, needle-nosed pliers may be needed in

order to grip the filter assembly).

d. Clean or replace the return air filter(s) as requ ired.

e. Close the filter channel and lock the 1/4 turn stud

into place by turning clockwise with 3mm Allen

wrench.

Loading...

Loading...