4-- 13© 2012 Mobile Climate Control T-299 Rev. 08/2012

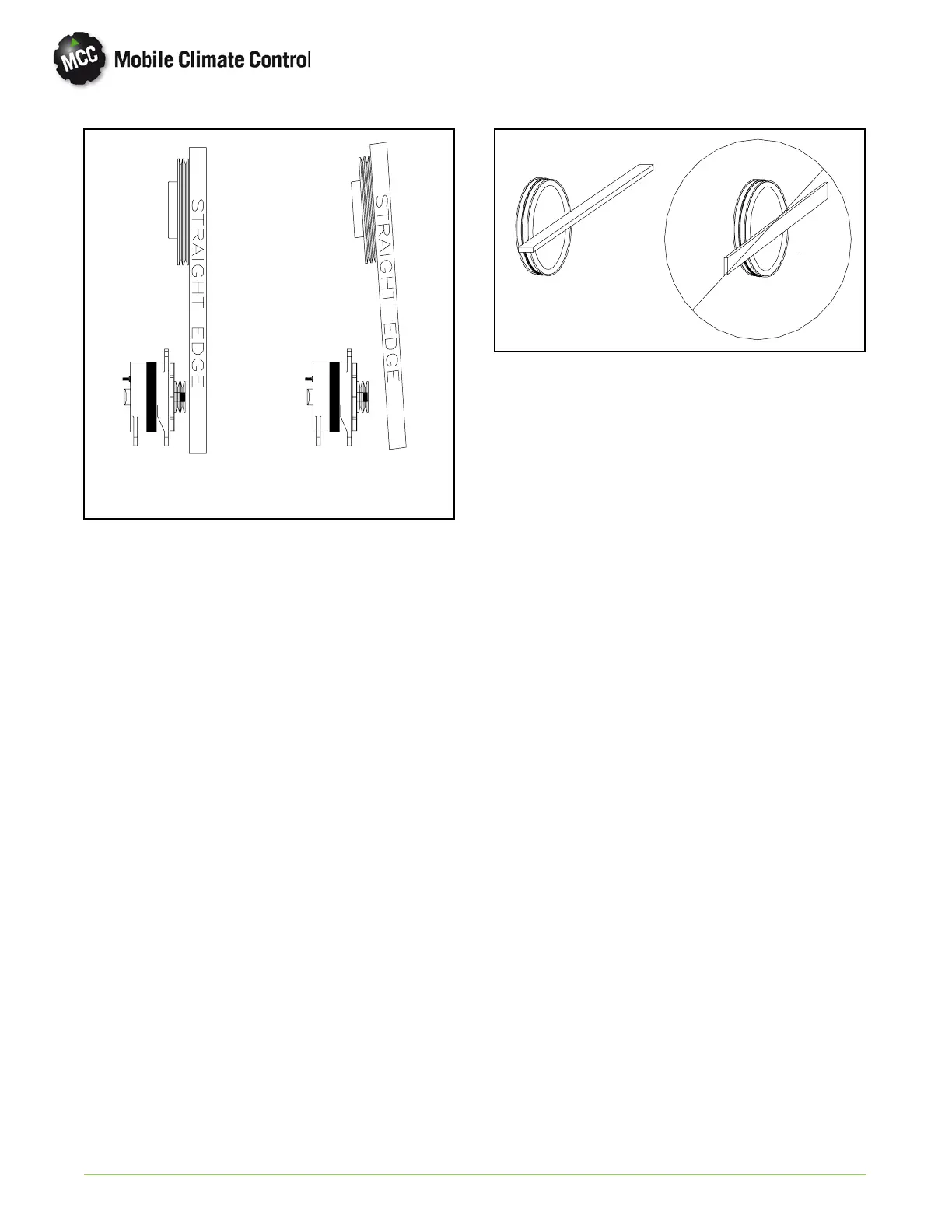

Parallel

Misalignment

Angular

Misalignment

Figure 4-6 Belt Misalignment

Parallel adjustment is designed into a mount for final

alignment during the installation process. Parallel

misalignment is corrected by moving the driven

pulley (alternator or compressor) into alignment

with th e drive pulley. This can be done using several

methods. Spacing the component forward or

rearward by adding or removing spacers is the most

popular method used to achieve proper alignment.

Other methods such as sliding the component

forward or rearwards using slide plates and/or slots

in the main weldment are also used.

Angular m isalignment is often caused by to lerances

in several pieces, such as hardware to mou nting holes

and plates to components. Angular misalignment is

corrected by loosening the mounting hardware,

adjusting the compressor/alternator to the proper

angle and retightening the mounting hardware.

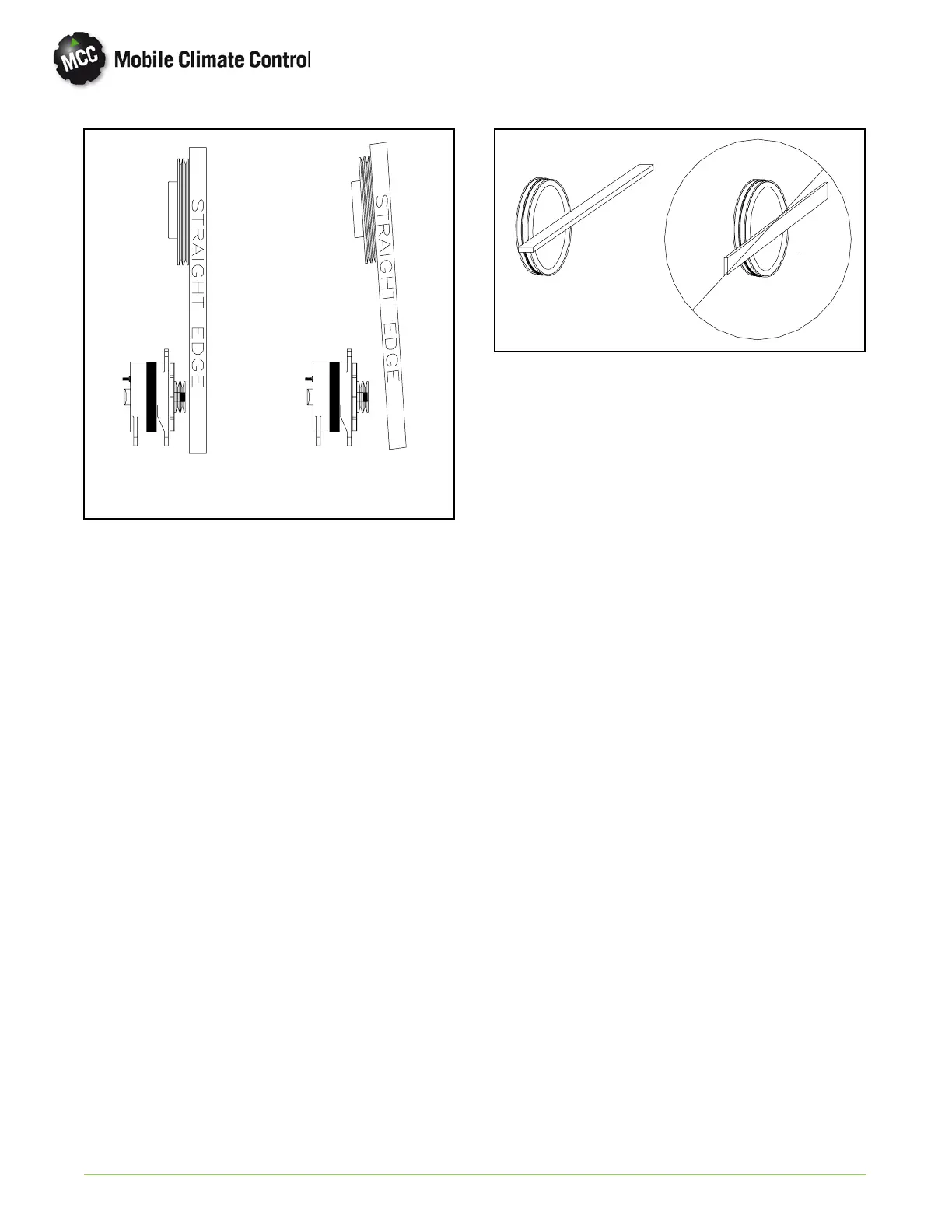

Correct

Incorrect

Figure 4-7 Straight-Edge Application

Proper use of a straight edge is illustrated in

Figure 4-7 . Never use a straight edge on the

wide/flat side, as th ey are n o t accurate. The thin edge

is a straight surface and the only accurate surface.

Thestraightedgemustbeflushacrossthefaceofthe

pulley. Then, to measure the alignment, lower the

other end down to the driven pulley(s). Adjustments

are made based on results of the aforementioned.

Note that the pulley rim width must be considered

when making the aforementioned measurements.

The next step is to lay the straight edge flush across

the face of the driven pulley. This is the best way to

determine angular misalignment. Again, adjust as

required. You should repeat this step for all pulleys

until acceptable alignment is achieved. No te th e

drive pulley is the primary guide for alignment. Do

not use idlers as a guide for proper component belt

alignment as bearing play could give you false

readings.

4.12.4 Drive Belt Tension Guidelines

Proper belt tension is essential for not only belt life,

but also the alternator and compressor life as well.

Heat is a major enemy o f compressors and

alternators that can cause unnecessary stress and

greatly reduce component life.

Listed in Table 4-9 are the examples specific to belt

tension concerns:

A. Under tension would promote belt slippage

causing excessive heat. Heat equ als premature

alternator and/or compressor failure.

B. Over tension could cause premature bearing

failure and excessive wear on drive and driven

components.

Proper belt tension is obtained by referring to

Table 4-9. Find the belt used and where applied

(compressor or alternator drive, Single ”V” or Ploy

”V” 4-8 ribs).

Loading...

Loading...