4-- 12© 2012 Mobile Climate Control T-299 Rev. 08/2012

Clearance Zone Identification

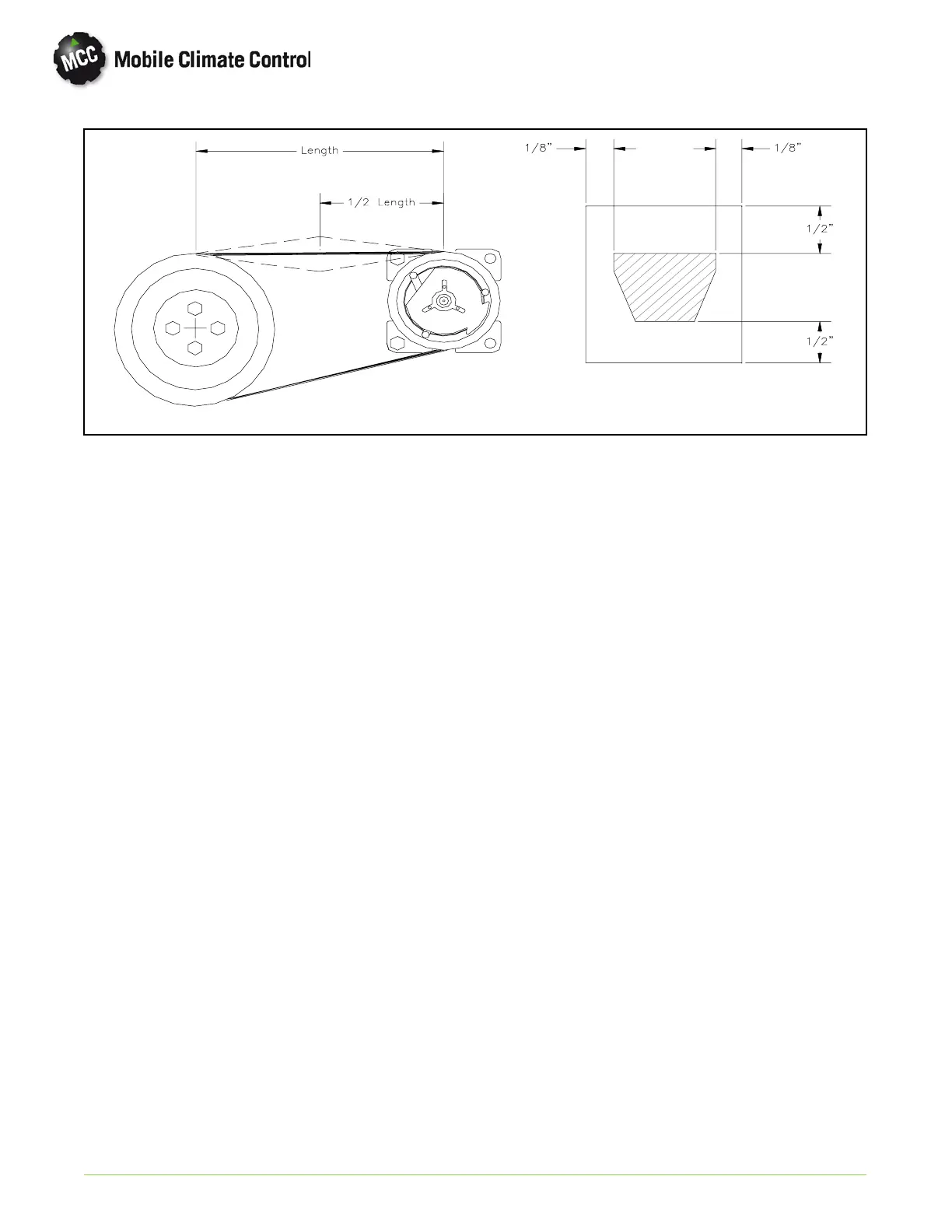

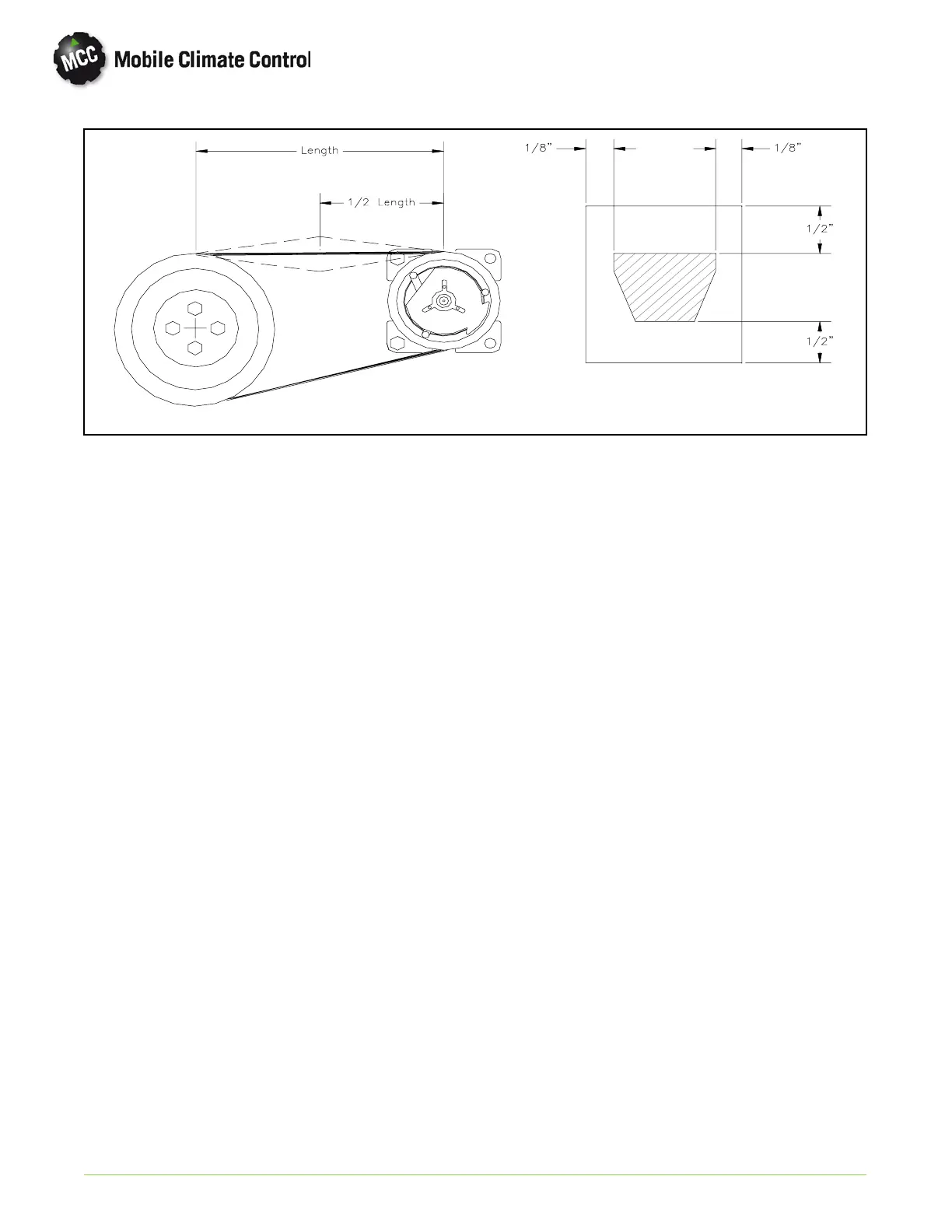

Clearance at Mid Span

Figure 4-5 Belt Clearance Requirements

4.12 DRIVE BELT INSTALLATION

4.12.1 Introduction

There are several factors that have major effects on

compressor and alternator drive belt(s) life

expectancy and reliability. Belt alignment and proper

tension being the most critical and controllable by

the installer and end-user. Improper alignment

and/or tension will cause premature failure of drive

belts, driven components as well as a possible safety

issue. When improperly installed and/or

maintained, drive belts can cause significant damage

to equipment. The following are the biggest factors

that effect belt life and system dependability.

A. Belt Alignment

B. Belt Tension

1. Over Tensioned

2. Under Tensioned

C. Belt Clearance

D. Temperature-Heat

E. Fluids

F. Maintenance Procedures

4.12.2 Belt Clearance

A certain belt clearance needs to be maintained for

belt span vibration when installing compressors and

alternator belts. Figure 4-5 shows the recommended

guidelines for clearance. Due to the large number of

variables, actual testing is required to determine

whether th e clearances are acceptable.

4.12.3 Pulley Alignment

Correct belt alignment is essential for alternator and

compressor belt life. The center line of all pulleys

related to compressor or alternator drive must be

within 1/3 degree of true center. Refer to Figure 4-6

for approximate measurements, and keep in mind,

these are maximum values. You should try to attain

perfect alignment whenever possible to maximize

component and belt life.

Maximum allowable run-out for Poly ”V” belts is

1/8 inch.

Maximum allowable run-out for Standard ”V” belts

is 1/4 inch.

Alignment methods are illustrated in Figure 4-6 and

Figure 4-7. A high quality straight edge is a necessity,

your eye is not an acceptable meth o d of determining

proper belt alignment. All mounting brackets should

allow for minor belt center line adjustments.

Loading...

Loading...