4-- 11© 2012 Mobile Climate Control T-299 Rev. 08/2012

Table 4-6 STANDARD TORQUE REQUIREMENTS

SIZE TUBE O.D. * FLARE

O-RING

THREAD **

STEEL TUBING ALUM. TUBING

4 1/4 inch (.250) 11-13 ft./lbs. 30-35 ft./lbs. 5-7 ft./lbs. 7/16

5 3/8 inch (.375) 15-17 ft./lbs. 30-35 ft./lbs. 8-10 ft./lbs 9/16

6 3/8 inch (.375) 18-20 ft./lbs. 30-35 ft./lbs. 11-13 ft./lbs 5/8

8 1/2 inch (.500) 36-39 ft./lbs. 30-35 ft./lbs. 15-20 ft./lbs 3/4

10 5/8 inch (.625) 52-57 ft./lbs. 30-35 ft./lbs. 21-27 ft./lbs 7/8

12 3/4 inch (.750) 71-79 ft./lbs. 30-35 ft./lbs. 28-33 ft./lbs 1-1/16

* The tube O.D. is measured at the point it passes through the nut. ** Thread pitch may vary.

4.10 TORQUE SPECIFICATIONS - REFRIGERANT

FITTINGS

All refrigerant hose fitting connections must be

torqued to the specifications listed in Table 4-6.

NOTE

No matter what typ e of lubricant (oil) usedin

the system, always use mineral oil to lubricate

the O-Rings and fittings. PAG oils will

absorb moisture and become very acidic and

corrosive. Mineral oil absorbs moisture at a

much lower rate than PAG oils.

4.11 TORQUE SPECIFICATIONS - BOLTS

The torque values listed in Table 4-7 and Table 4-8

are are based on the use of lubricated threads.

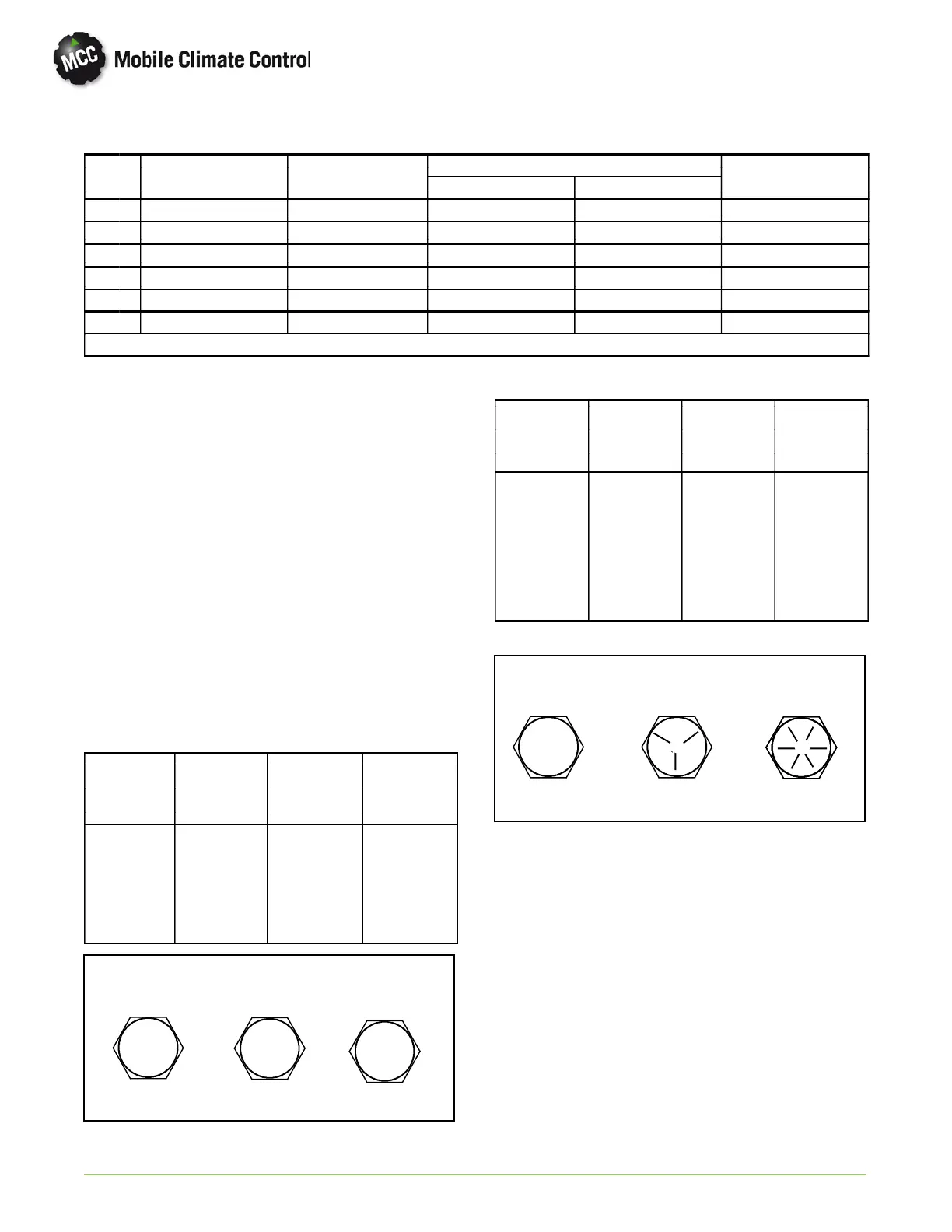

Table 4-7 Metric Torque Specs

Bolt Size

Dia. mm

Torque

(Ft-Lb

Cast Iron

Grade 8.8

Torque

(Ft-Lb

Cast Iron

Grade 10.9

Torque

(Ft-Lb

Cast Iron

Grade 12.9

6

7

8

10

12

14

16

7

10

18

30

55

85

130

9

13

23

45

75

120

175

9

18

27

50

95

145

210

8.8 10.9

12.9

Commercial Grade Head Markings

Metric Bolts

Grade 8.8 Grade 10.9

Grade 12.9

Figure 4-3 Metric Bolt Markings

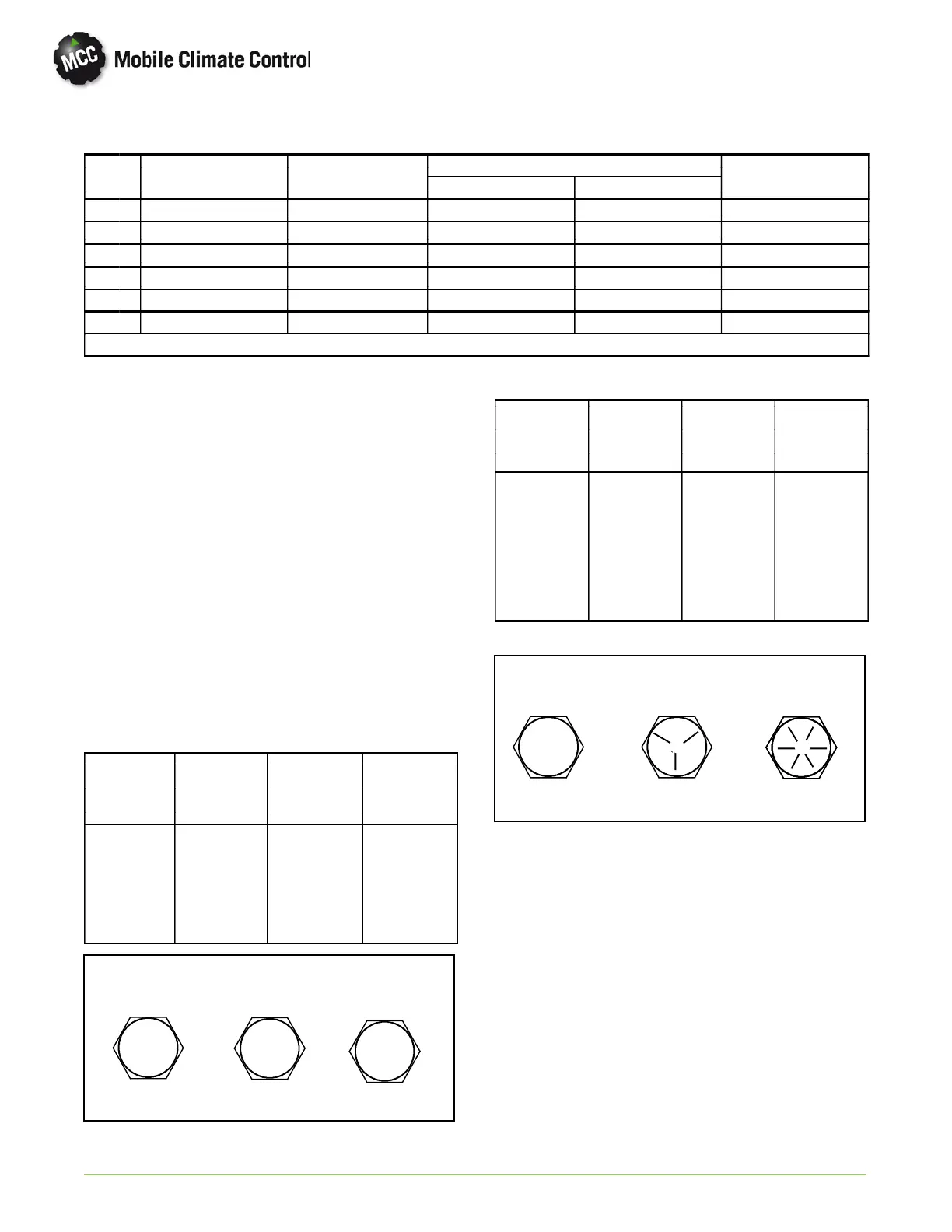

Table 4-8 U.S. Torque Specs

Bolt Size

Dia. mm

Torque

(Ft-Lb)

Cast Iron

Grade 2

Torque

(Ft-Lb

Cast Iron

Grade 5

Torque

(Ft-Lb

Cast Iron

Grade 8

1/4-20

5/16-18

3/8-16

7/16-14

7/16-20

1/2-13

1/2-20

5/8-11

5/8-18

5

10

18

30

32

45

50

82

93

7

15

30

45

50

70

75

135

155

11

22

40

65

70

95

110

190

215

Commercial Grade Head Markings

U.S. Customary Bolts

Grade 5

Grade 8

Grade 2

Figure 4-4 U.S. Bolt Markings

4.11.1 Electrical Control Panel - Torque Values

Torque values for all Split-System electrical panels

are as follows.

1. Torque value for wire connections at the plastic

circuit breakers are: 24 In-Lbs max.

2. Plastic Breaker mounting screw torque is:15

In-Lbs.

3. Torque value for wire connections at the plastic

terminal strip are: 25 In-Lbs max.

4. Terminal Strip m ounting screws are: 25 In-Lbs

max.

Loading...

Loading...