14

Where replacement parts are necessary for periodic maintenance and servicing, genuine factory

replacement parts must be used to restore your equipment to original specifications. The manufacturer

will not claim responsibility for damages as a result of the use of unapproved parts.

If equipment has been altered in any way from original design, the manufacturer does not accept any

liability for injury or warranty.

MAINTENANCE AND SERVICE

Maintenance Schedule

After the first 12 hours of use, check tightness of bolts, especially those on the C-springs. Torque

specifications are listed in appendix A and the gang arbor bolt torque is defined in the “Disk Gang and

Blades” section below.

Prior to each use, check for loose bolts and replace lost or worn parts.

Parts diagrams and listings for service and repair references may be found in appendix B.

Grease hinge pins every 15 hours.

Grease spiral reel and disk bearings every 50 hours (sparingly).

Grease rolling basket bearings every 50 hours (sparingly).

Grease wheel bearings every 50 hours (sparingly) and check for endplay. Repack annually.

Note: Clean grease fittings and replace those that are broken or missing. Over greasing may damage

bearing seal and cause premature bearing failure.

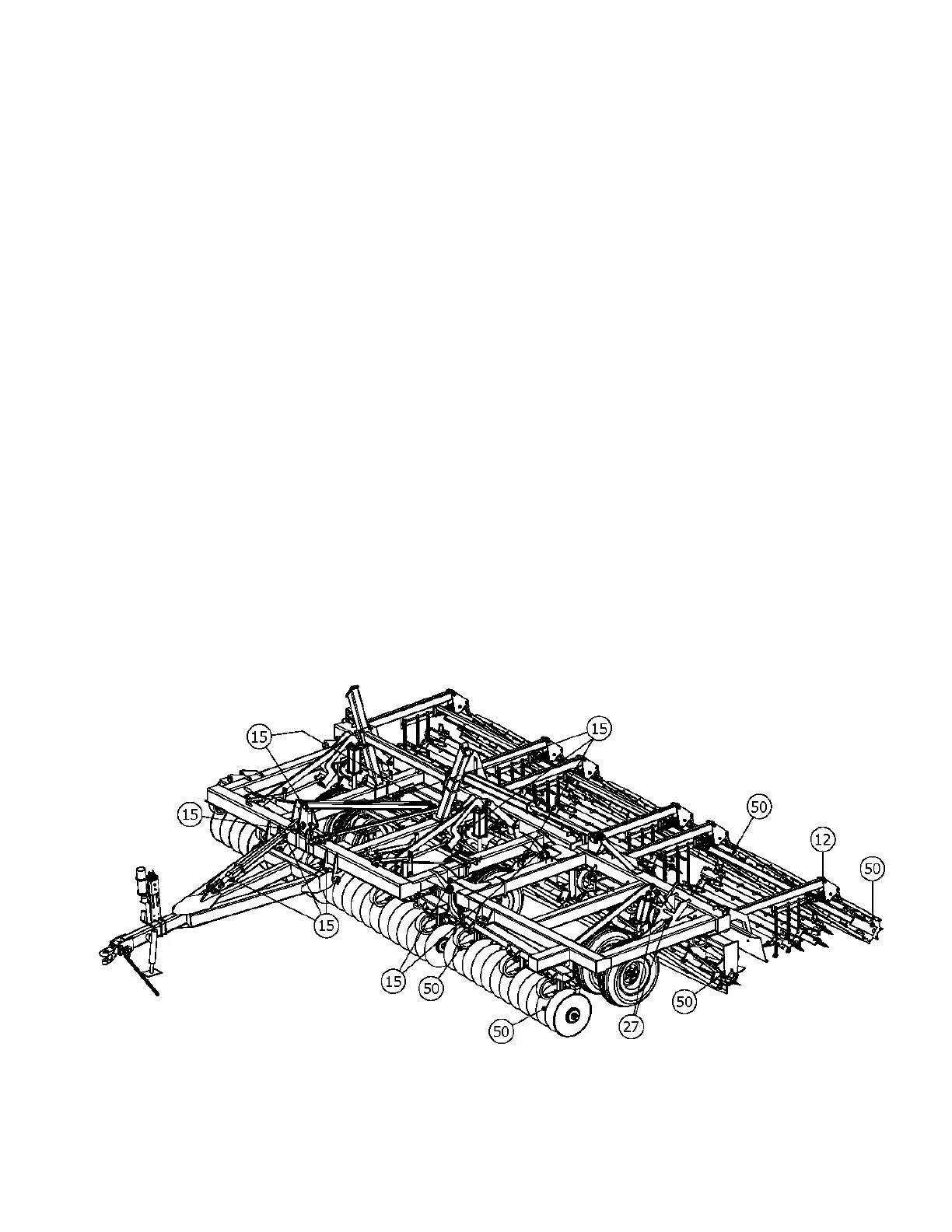

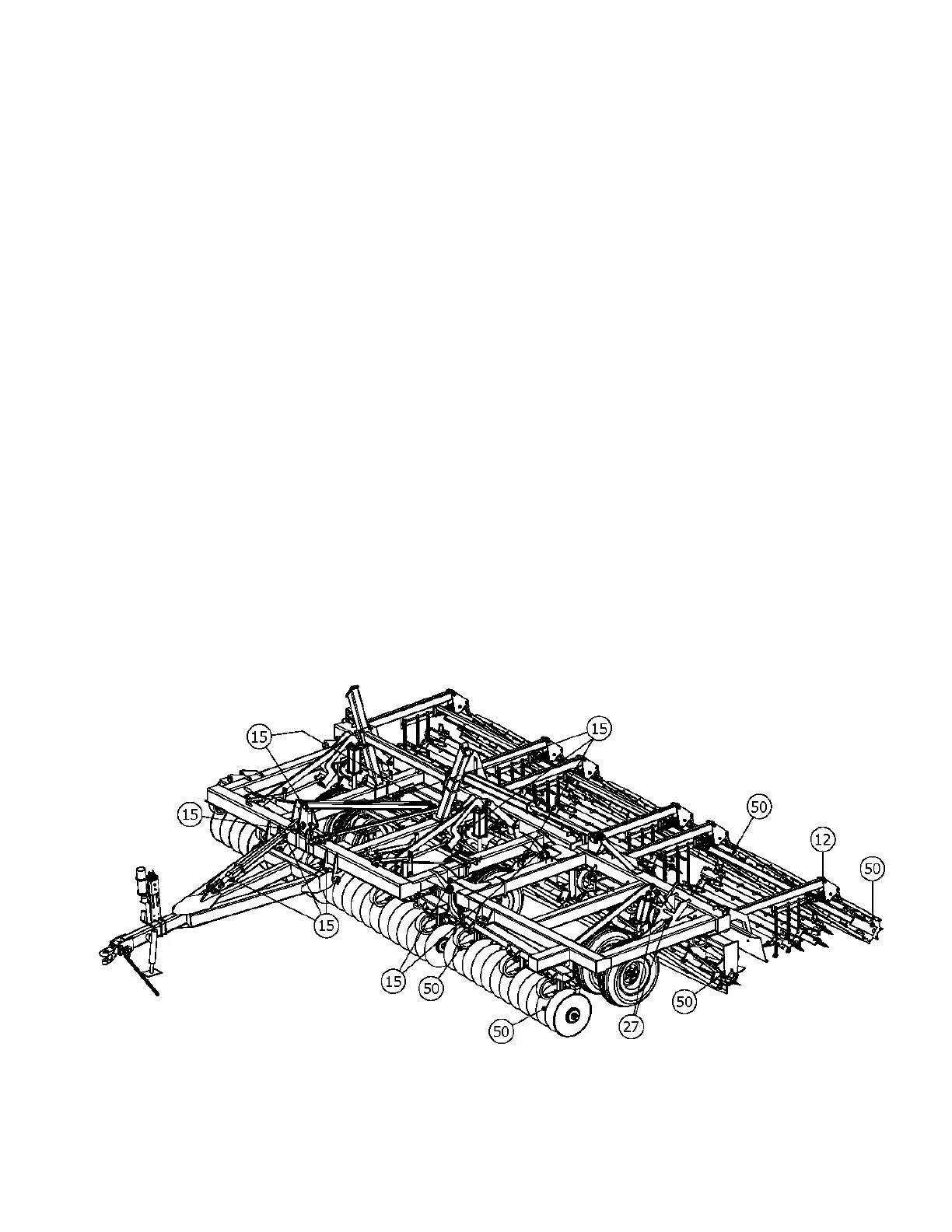

Grease Fitting Locations

Number indicates grease interval in hours of operation.

Loading...

Loading...