CONDENSER

GENERAL

-

For proper performance, the condenser water

must enter the bottom connection of the condenser. Water

cooled condensers may be piped for use with cooling towers,

well water or heat recovery applications. Cooling tower ap-

plications should be made with consideration to freeze pro-

tection and scaling problems. For specific applications, con-

tact cooling tower manufacturer for equipment characteristics

and limitations.

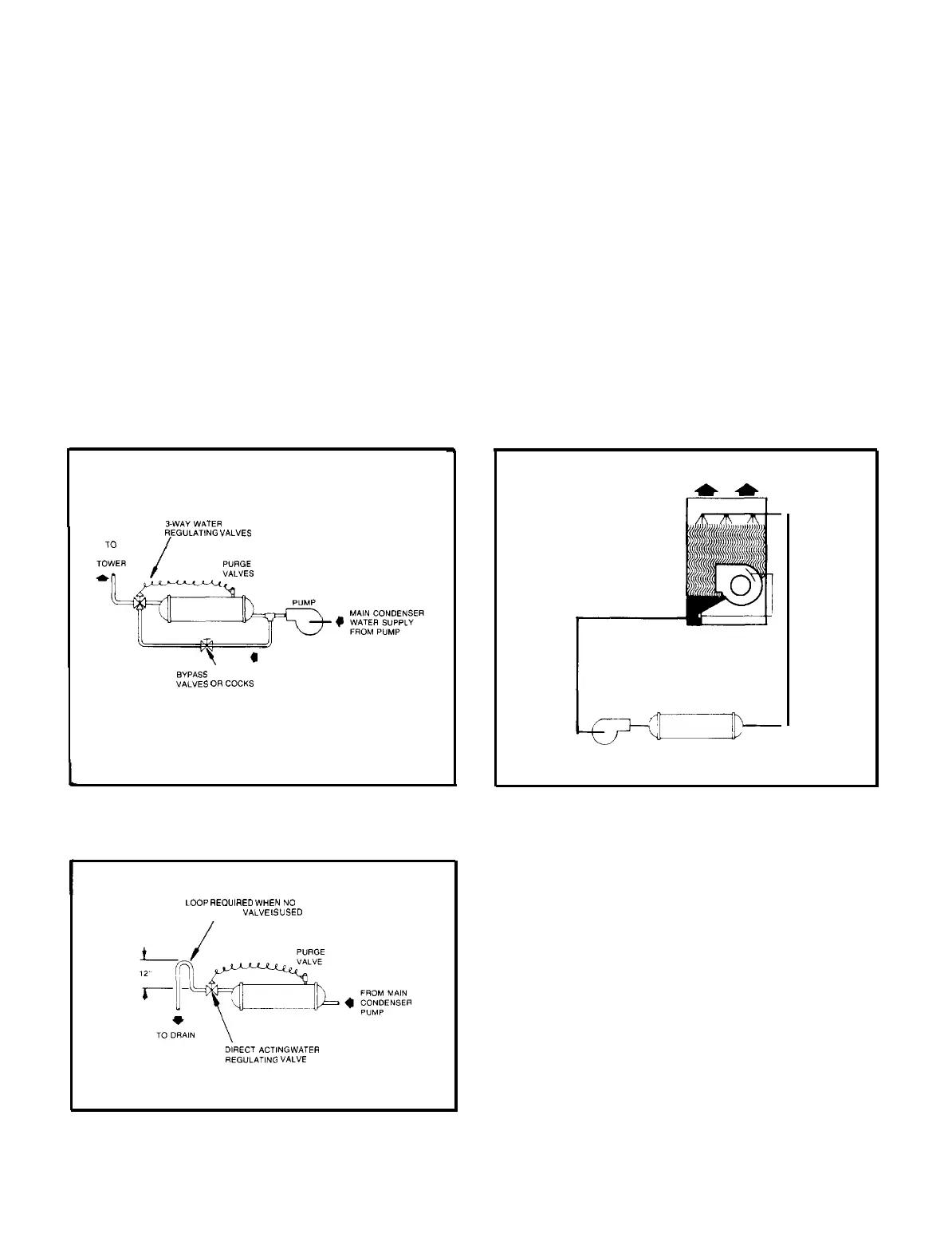

HEAD PRESSURE CONTROL, TOWER SYSTEM

-

Some

means of controlling operating head pressure must be pro-

vided. Minimum condensing temperature allowed is 80°F.

Minimum entering tower condenser water temperature is

70°F. Typical systems are shown in Figures 8 and 9. In Figure

8, a three-way pressure actuator water regulating valve is

used for cooling applications, In Figure 9 the capacity of the

cooling tower is controlled through damper and/or fan

WATER PIPING

modulation. These typical systems, depending on the specific

application, must maintain a constant condensing pressure,

regardless of temperature conditions and must assure

enough head pressure for proper thermal expansion valve

operation. Note also that both systems assure full water flow

to the tower.

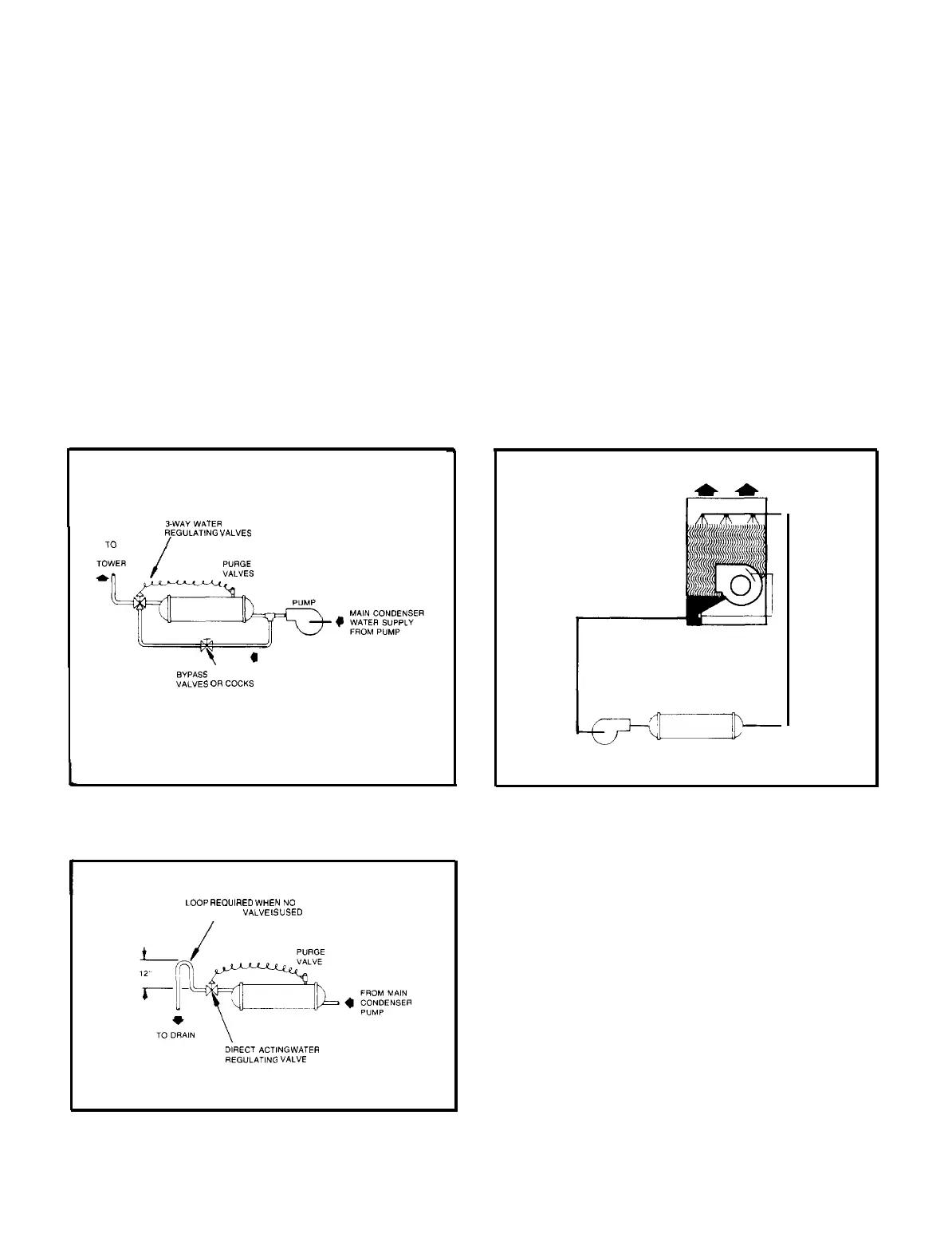

HEAD PRESSURE CONTROL, WELL WATER SYSTEM

-

Where well water is used for condensing refrigerant, a direct

acting water regulating valve is recommended (see Figure

10). The valve is normally installed at the outlet of the con-

denser. On shutdown, the valve will close and, in this way,

prevent water siphoning out of the condenser. Siphoning

causes drying of the waterside of the condenser and rapid

build-up of fouling. When no valve is used, a loop at the outlet

end is recommended (See Figure 10).

COOLING TOWER SYSTEMS-HEAD PRESSURE CONTROL

Figure 8. 3-Way Water Valve

Figure

9. Fan

Modulation

REGULATING VALVES

TO

COOLING

BYPASS

BALANCING

VALVES

OR

COCKS

Figure 10. Well Water Cooling System

I

LOOP REOUIAED WHEN

NO

REGULATING VALVE

IS

USED

DIRECT

ACTlNG

WATER

REGULATING VALVE

COOLING TOWER

Page 10 I IM 508

Loading...

Loading...