Single circuit heat recovery employs a standard water

cooled chiller equipped with heavier electrical components

and a 380 psig high pressure limit switch. These modifica-

tions allow leaving condenser water temperatures up to 135°F

for building or process heating applications.

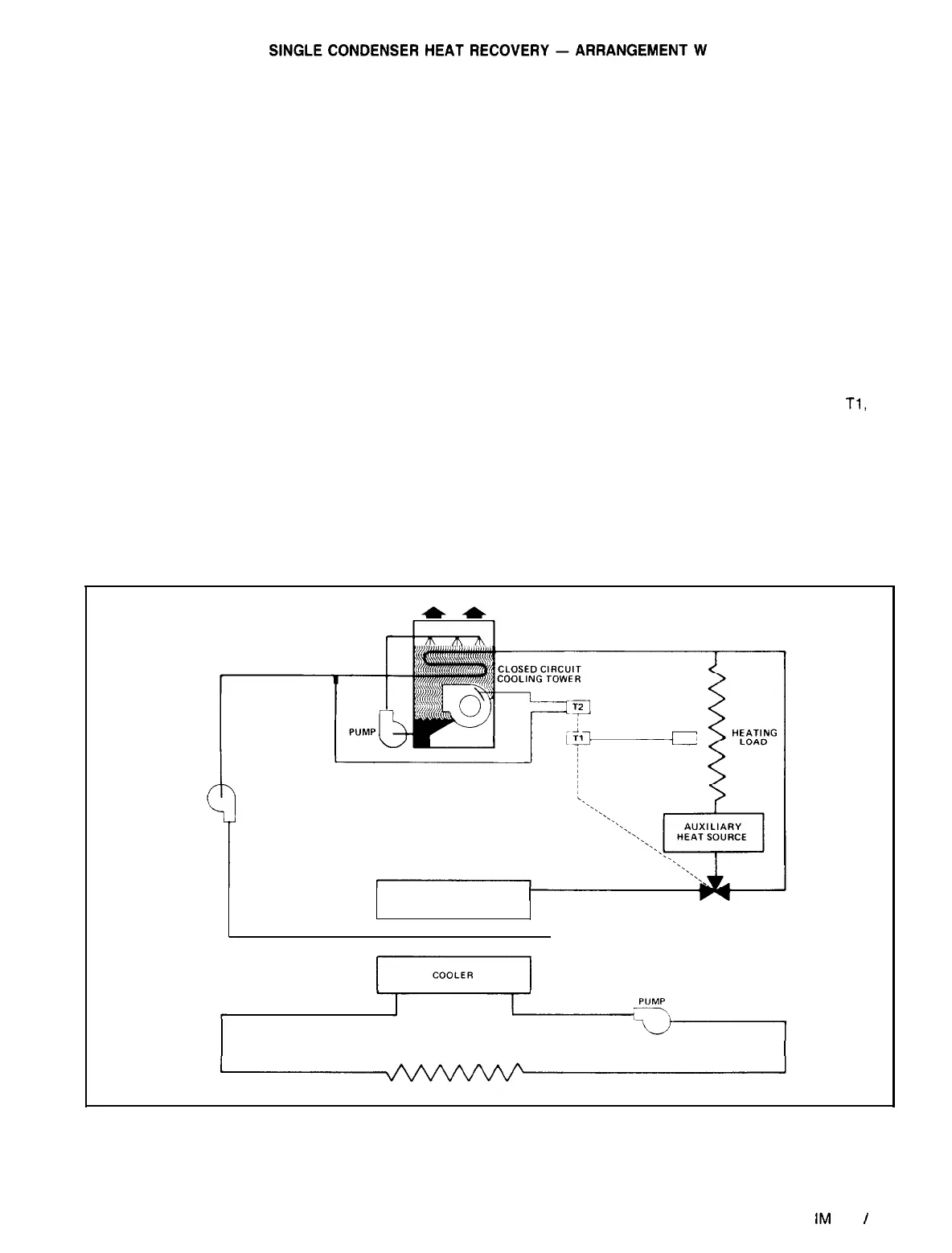

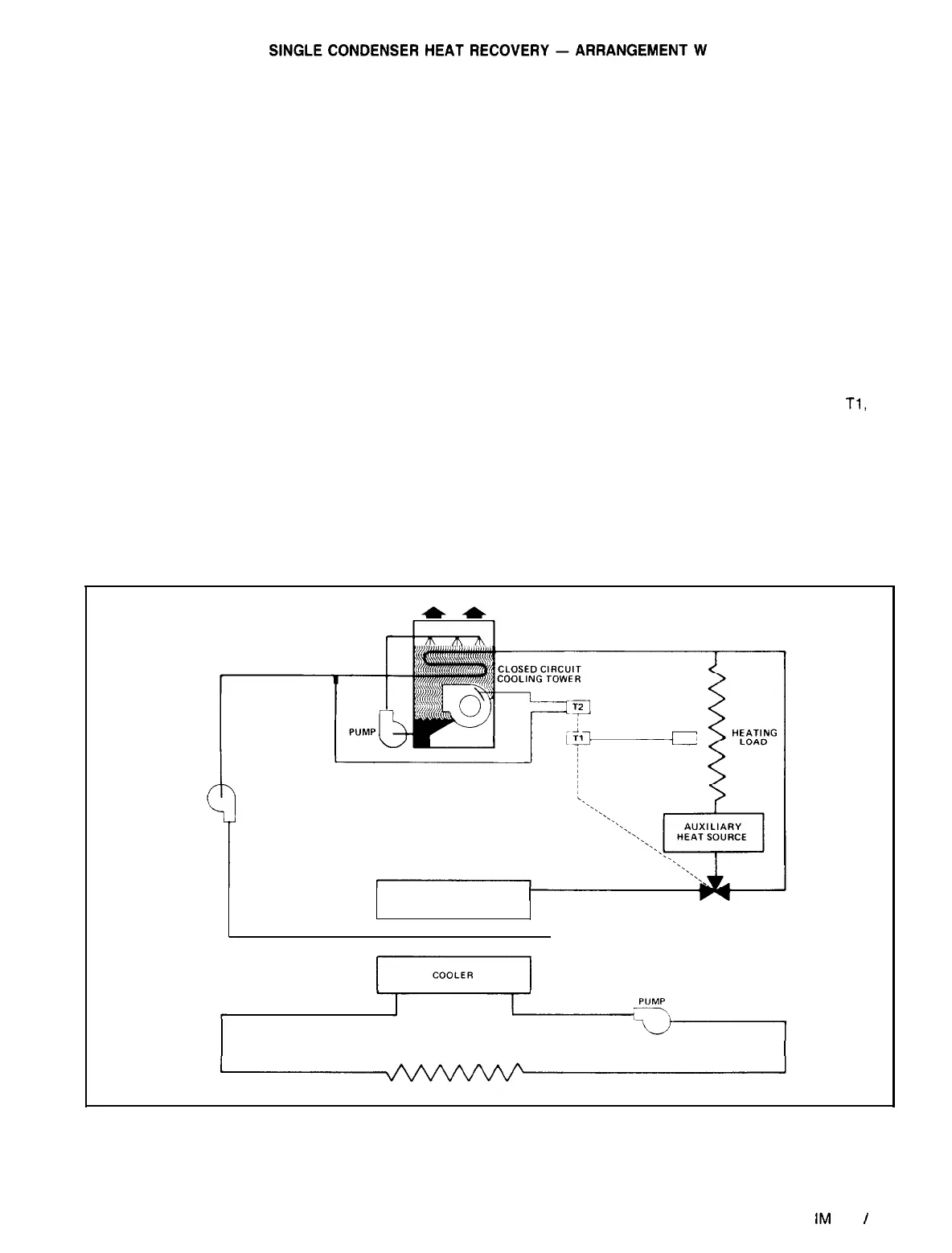

A typical heat recovery arrangement will include a closed

circuit cooling tower used to reject unwanted condenser heat

to the outdoor ambient air. The cooling tower should be

sized to reject all the condenser heat during summer design

operation. This insures proper operation in the

nonheat-

recovery mode. Use of a closed circuit tower is normally re-

quired in order to prevent fouling of heating coils in the heat

recovery loop. Condenser water remains free of contamina-

tion from minerals and impurities normally contained in make-

up water in an open cooling tower.

If a closed circuit cooling tower is to be located in an am-

bient temperature below freezing, protection against coil and

sump freeze-up must be provided. Coil freeze protection can

be provided by using a glycol solution or by maintaining a

heat load on the coil

at all times and maintaining water flow

through the coil. Sump water freeze protection can be pro-

vided by locating the spray water circulating pump and sump

tank inside a heated space or by placing heating coils in the

sump. Head pressure and water temperature are normally

controlled by the tower capacity control. Adequate capacity

control is usually obtained by fan cycling and regulating

dampers located in the fan discharge. This will maintain a

constant tower water temperature. Consult the closed circuit

manufacturer for information on specific applications.

An auxiliary heat

source is necessary if the available con-

denser heat is not sufficient to satisfy all of the heat load.

The auxiliary heat source must be located between the con-

denser and the heat load and the control should be inter-

locked with the closed circuit tower to prevent auxiliary

heating while rejecting heat to the ambient.

When the heating load is satisfied, a two-position, three-

way valve is set to divert condenser water around the heat

load and the auxiliary heat source. Whether operating in sum-

mer or winter, the chiller is always controlled by the cooling

load and not the heating load.

TYPICAL OPERATION

-

On a call for cooling, the chiller

starts and hot condenser water flows through the diverting

valve to the closed circuit cooling tower rejecting heat to the

outdoors. The tower dampers modulate to maintain a pro-

per entering condenser water temperature which will give ef-

ficient operation by means of the proportional controller T2

located in the outlet fluid line of the tower.

When a heating load is sensed by mode switch

Tl,

the

three-way valve is switched to allow condenser water to flow

through the heating circuit. The proportional controller T2 is

also reset upwards to give the desired water temperature for

heat recovery. The unused condenser heat will be rejected

out through the closed circuit tower. If the condenser heat

of rejection cannot satisfy the heating load after an ap-

propriate delay, the auxiliary heat source will be activated.

Figure

11. Typical Single Condenser (Per Refrigerant Circuit) Heat Recovery

PUMP

HEATRECOVERY

CONDENSER

TWO POSITION

DIVERTING VALVE

COOLING LOAD

NOTE: The schematic shows one refrigerant circuit. Models with two refrigerant circuits have two condensers

IM

508

I

Page 11

Loading...

Loading...