IM-447 / Page 15

MicroTech Network Control System

Each Console Heat Pump Unit is available with a MicroTech

Unit Controller. The unit controller is a factory mounted,

preprogrammed and pre-tested stand-alone microprocessor

capable of communicating to a local personal computer

through the MicroTech Network Master Panel.

The MicroTech control system includes unit-mounted

return air; discharge air and leaving water temperature

sensors; tenant setpoint adjustment knob and an optional

tenant override button; and the capability of replacing the

return air sensor with a wall-mounted room sensor.

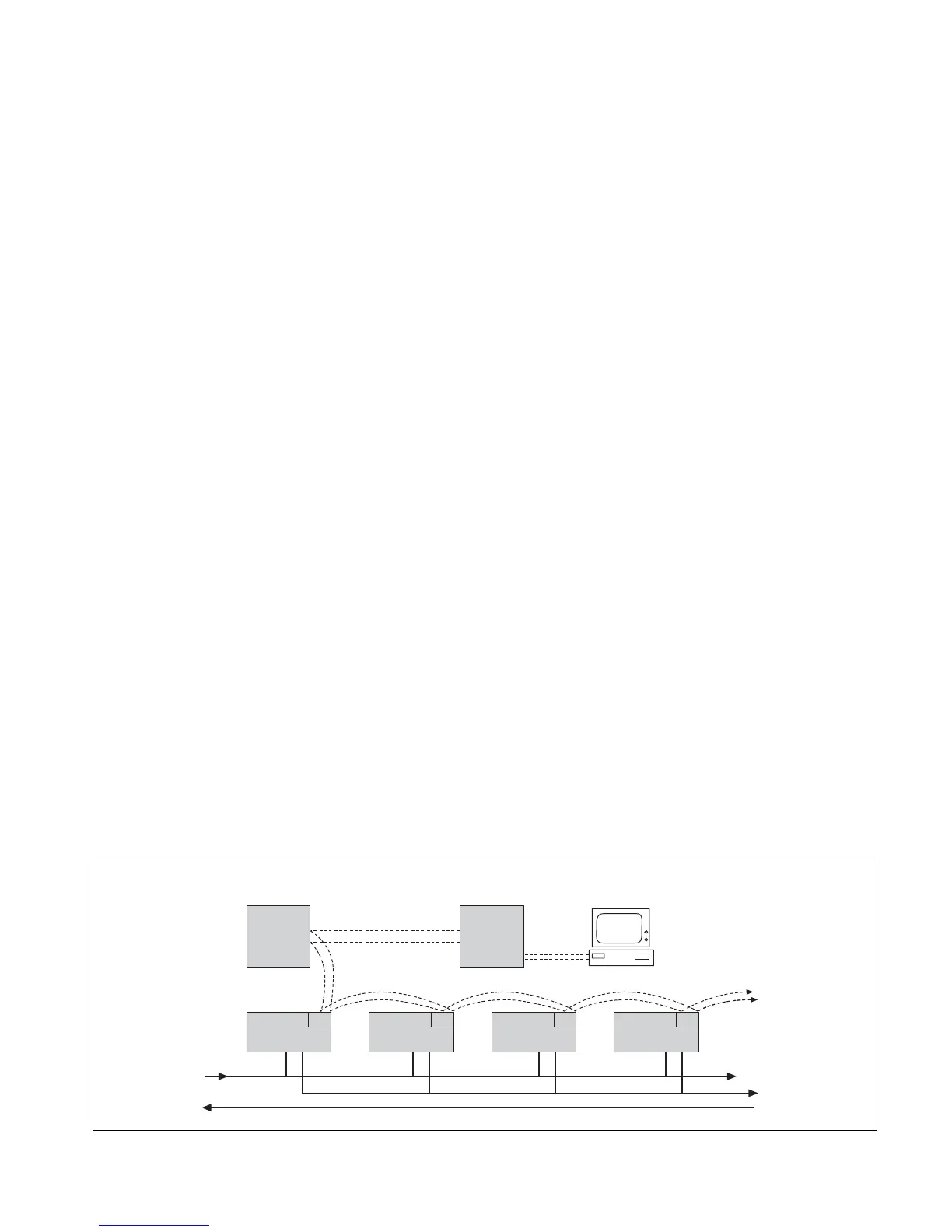

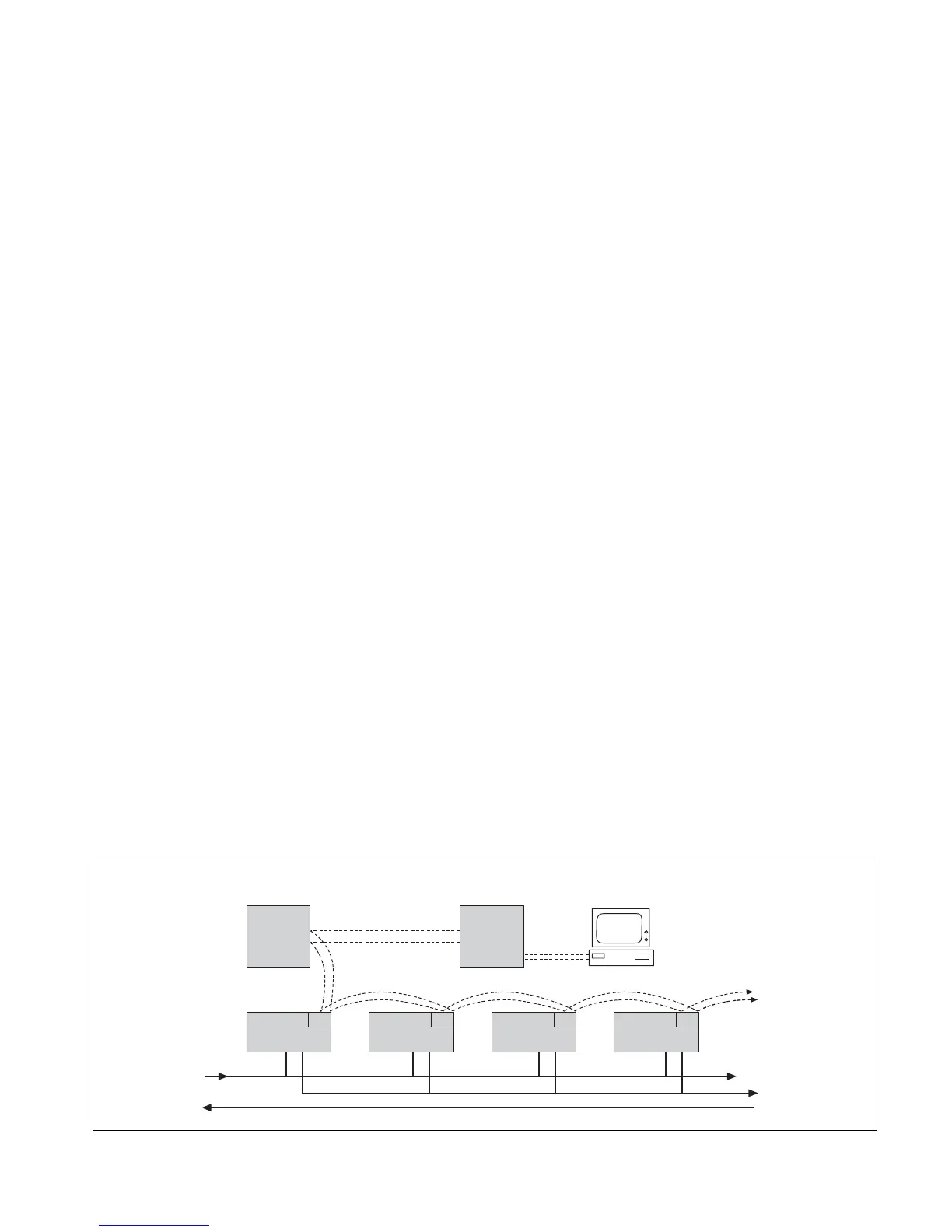

The MicroTech Network Control System is a fully

distributed, direct digital control (DDC) system which allows

the owner to control and monitor water source heat pump

units and auxiliary equipment through a personal computer

to maintain comfort conditions.

The PC has the ability to communicate with each heat

pump unit and with the entire system through two dedicated

conductors, twisted and shielded, in a “daisy chained”

format. Each controller utilizes EEPROM microprocessor

technology, retaining programmable setpoint parameters and

control logic. Each controller may operate as stand-alone,

independent of the network communications and will:

• Control heating and cooling from a return air sensor.

• Provide fan and compressor operation.

• Monitor all safety controls.

• Monitor discharge air temperature.

• Monitor leaving water temperature.

• Provide status of all vital unit functions.

• Provide optional control output.

The MS-DOS compatible software package allows the

operator to interface with each unit controller into the entire

network. Parameters within each controller are factory set

but can be changed from the PC. All control sequencing,

stop/start and safety monitoring is displayed on the PC

screen with the following unique values and parameters for

each unit:

• Return air, discharge air and entering water temperatures.

• Compressor, fan and reversing valve status.

• High pressure, low temperature, brownout and drain pan status.

• Occupied and unoccupied heat and cool setpoints.

• Auto/manual and occupied/unoccupied fan control.

• Mode, fault, system, schedule and setpoint operation.

• Compressor starts and fan run hours.

• Load shed level and tenant override.

In addition, the following unique operation and

maintenance parameters can be displayed for each unit:

• Leaving water temperature

• Return air temperature setpoint adjustment

• Adaptive optimal start

• Occupied/unoccupied (on/cycle) fan mode

• Room temperature warning

• Filter changes from fan hours

• Compressor management: On/off differential, maximum

off time, maximum cycle

Time schedules can be graphically displayed showing start/

stop times for each day of the week and holidays. Up to 16

holiday dates and duration cycles can be set for a total of

240 possible holiday dates. Each heat pump can be assigned

to a different time schedule and any number of heat pumps

can be assigned to the same time schedule.

Group summary screens are available to display various

parameters for 12 units. Screens are grouped to cover major

groups such as temperatures, setpoints and status.

Control and monitoring of the entire water source heat

pump system through the MicroTech Network includes the

MicroTech Loop Water Controller and Application Specific

Controllers complete with graphic displays.

Wall-mounted room sensors are available to control the

heating and cooling operation of each MicroTech Unit

Controller. These include a basic room sensor with optimal

override, LED status and tenant setpoint adjustment.

For remote access, a Modem Access Unit allows a remote

PC to call the MicroTech Network through phone lines as

well as allowing the MicroTech Network to dial predefined

phone numbers.

Personal

Computer

Heat Pump

MicroTech

Network Master Panel

MicroTech

Loop Water Controller

Heat Pump Heat Pump Heat Pump

Communications To

Additional Units

Supply

Return

Network graphic

Loading...

Loading...