ENGLISHen

12

a suitable dust collector attached to the saw.

The dust collector must comply with the data

stated in the technical specifications.

See to it that only as little as possible wood dust

will get into the environment:

– Remove wood dust deposit in the work area

(do not blow away!);

– fix any leakages on the dust collector;

– ensure good ventilation.

Hazard generated by modification of

the machine or use of parts not tested and

approved by the equipment manufacturer!

Assemble the machine in strict accordance with

these instructions.

Use only parts approved by the manufacturer.

This applies especially to:

– Saw belts (see "Technical Specifications" for

stock nos.);

– safety devices (see "Technical Specifications"

for stock nos.).

Do not change any parts.

Caution!

The use of other tools and accessories can result

in a risk of injury.

Hazard generated by machine defects!

Keep the machine and accessories in good

repair. Observe the maintenance instructions.

Before every use check the machine for

possible damage: before operating the machine

all safety devices, protective guards or slightly

damaged parts need to be checked for proper

function as specified. Check to see that all

moving parts work properly and do not jam. All

parts must be correctly installed and meet all

conditions necessary for the proper operation of

the machine.

Damaged protection devices or parts must be

repaired or replaced by a qualified specialist.

Have damaged switches replaced by a service

centre. Do not operate the machine if the switch

can not be turned ON or OFF.

Keep handles free of oil and grease.

Keep cutting tools clean and sharpened in able

to work better and safer.

Do not used damaged or deformed saw belts.

Risk of injury by noise!

Wear hearing protection.

Danger from blocking workpieces or

workpiece parts!

If blockage occurs:

1. switch machine off,

2. unplug mains cable,

3. wear gloves,

4. Clear the blockage using a suitable tool.

4.1 Symbols on the Machine

Danger!

Disregard of the following warnings may lead

to serious personal injury or material

damage.

Read instructions.

Wear protective goggles and ear

protectors.

Disconnect the mains plug before

starting any setting, maintenance or

repair work.

Do not direct the light beam into the

eyes of people or animals.

Wear ear protectors.

Height adjustment

Set saw belt track.

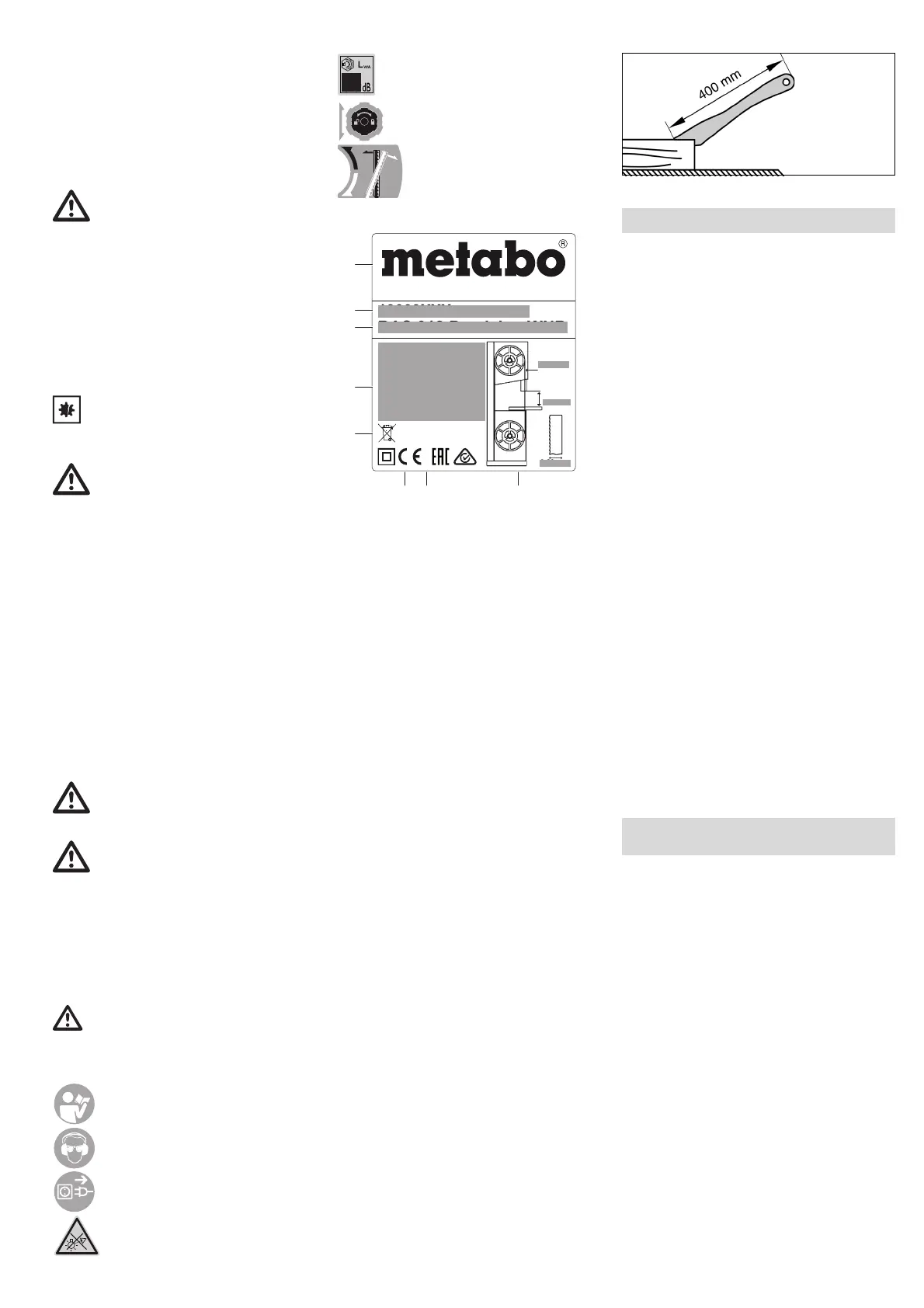

Information on the nameplate:

(a) Manufacturer

(b) Serial number

(c) Device designation

(d) Motor data (see also "Technical data")

(e) Disposal symbol – Device can be disposed of

via the manufacturer

(f) CE mark – This device fulfils the EU

Directives according to the Declaration of

Conformity

(g) Year of manufacture

(h) Dimensions of permitted saw belts

4.2Safety Devices

Upper belt guard

The upper saw belt guard (6) protects against

inadvertent contact with the saw belt and against

flying chips.

So that the upper saw belt cover provides sufficient

protection against contact with the saw belt, the

upper saw belt guide must be at least 3 mm from

the work piece.

Lower saw belt guard

The lower saw belt cover (7) protects against

inadvertent contact with the saw belt beneath the

sawing table.

The lower saw belt guard must be installed during

operation.

Housing doors

The housing doors (4) protect against contact with

the powered parts inside the saw.

The housing doors are equipped with interlocking

contacts. These turn the motor OFF when one

housing door is opened while the saw is running.

The housing doors must be closed while the

machine is in use.

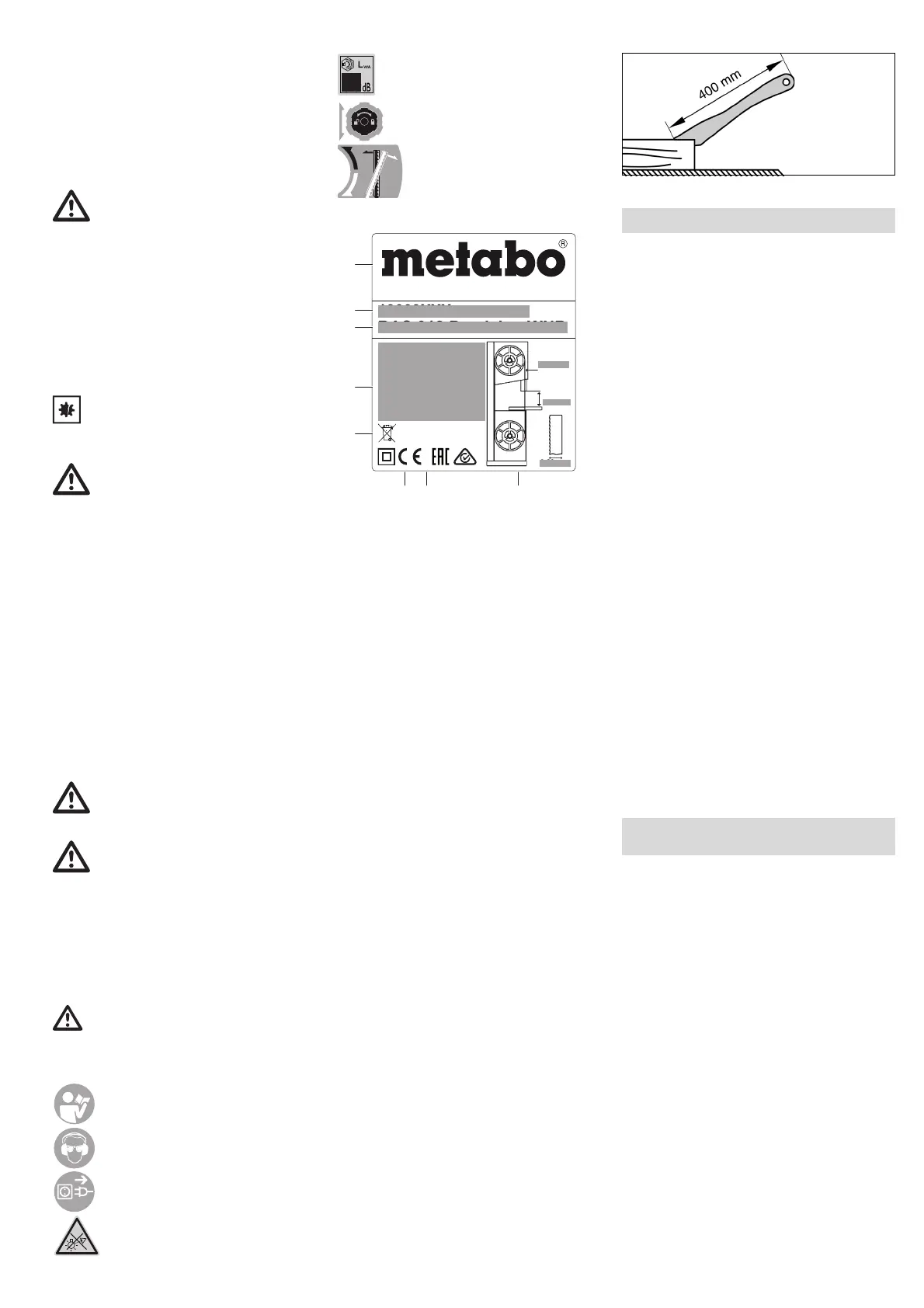

Push stick

The push stick (8) serves as an extension to the

hand and protects against inadvertent contact with

the saw belt.

The push stick must always be used if the distance

between the saw belt and a rip fence is less than

120 mm.

The push stick must be held at angle of 20° … 30°

to the surface of the saw table.

Replace push stick if damaged.

See page 2 - 3.

1 On/off switch cutting line illumination

2On switch

3 Off switch

4Housing doors

5 Turn-lock fastener for opening the housing

door

6 Upper saw belt guard (on the upper belt guide)

7 Lower saw belt guard

8Push stick

9Hole in saw table

10 Saw table

11 Table insert

12 Chip extraction nozzle

13 Clamping screw (inclination setting saw table)

14 Saw table fastening screws

15 Rip fence screw on saw table

16 Fence guide extrusion

17 Parallel stop

18 Parallel stop clamping lever

19 Setting knob for saw belt tension

20 Mitre fence

21 Clamping handle on the mitre fence

22 Setting knob (height adjustment for the upper

belt guide)

23 Lock nut (height adjustment for the upper belt

guide)

24 Upper belt guide

25 Dust guard strip

26 Lock nut (for setting knob for the angle of the

upper band saw rollers)

27 Setting knob for the angle of the upper band

saw rollers

28 Upper thrust bearing

29 Screws for upper thrust bearing

30 Upper guide bearing

31 Screw for upper guide bearing

32 Lower thrust bearing

33 Screws for lower thrust bearing

34 Lower guide bearing

35 Screw for lower guide bearing

6.1 Unpacking

Unpack and transport saw with assistance from a

second person.

Do not lift or transport saw by holding the upper

saw belt guard (6).

6.2 Fix saw

For a safe stand, the saw has to be fixed on a

stable base.

Fasten to work bench:

1. Drill four holes in the supporting surface.

2. Put fixing bolts through the base plate and

secure with nuts.

6.3 Installing the Saw Table

1. Guide saw table (10) over the saw belt and

place on the saw table guide.

2. Fasten saw table to the saw table guide with

four screws (14) and washers - do not tighten,

align the saw table first (See chapter 6.4).

6.4 Align the saw table

The saw table needs to be aligned in two planes

– laterally so that the belt runs accurately in the

middle of the table insert;

– at right angles to the saw belt.

BAS 318 Precision WNB

YYYY

19009XXX

9997812345

Metabo- Allee 1, D-72622 Nuertingen,

Germany; Made in China

L=2240 mm

max.

170 mm

6-20 mm

1~ 220-240 V

I = 4,0 A

P 0,66 kW S1 100%

2

P 0,9 kW S1 100%

1

50 Hz 410/880 m/min

60 Hz 490/1000 m/min

(a)

(b)

(c)

(d)

(e)

(f) (g) (h)

5. Overview

6. Unpacking, Erection,

Assembly and Transport

Loading...

Loading...