3. Meyer Hydraulic Fluid M-1 is specially formulated with an anti-ice

additive for almost constant viscosity in subzero temperatures.

Because it is free-flowing in extreme cold, the unit's performance

and efficiency are not affected by winter weather. It is effective for a

maximum of one year. Always carry an extra quart of Meyer

Hydraulic Fluid M-1 or equal fluids. Use of any inferior fluids will

void the Meyer warranty.

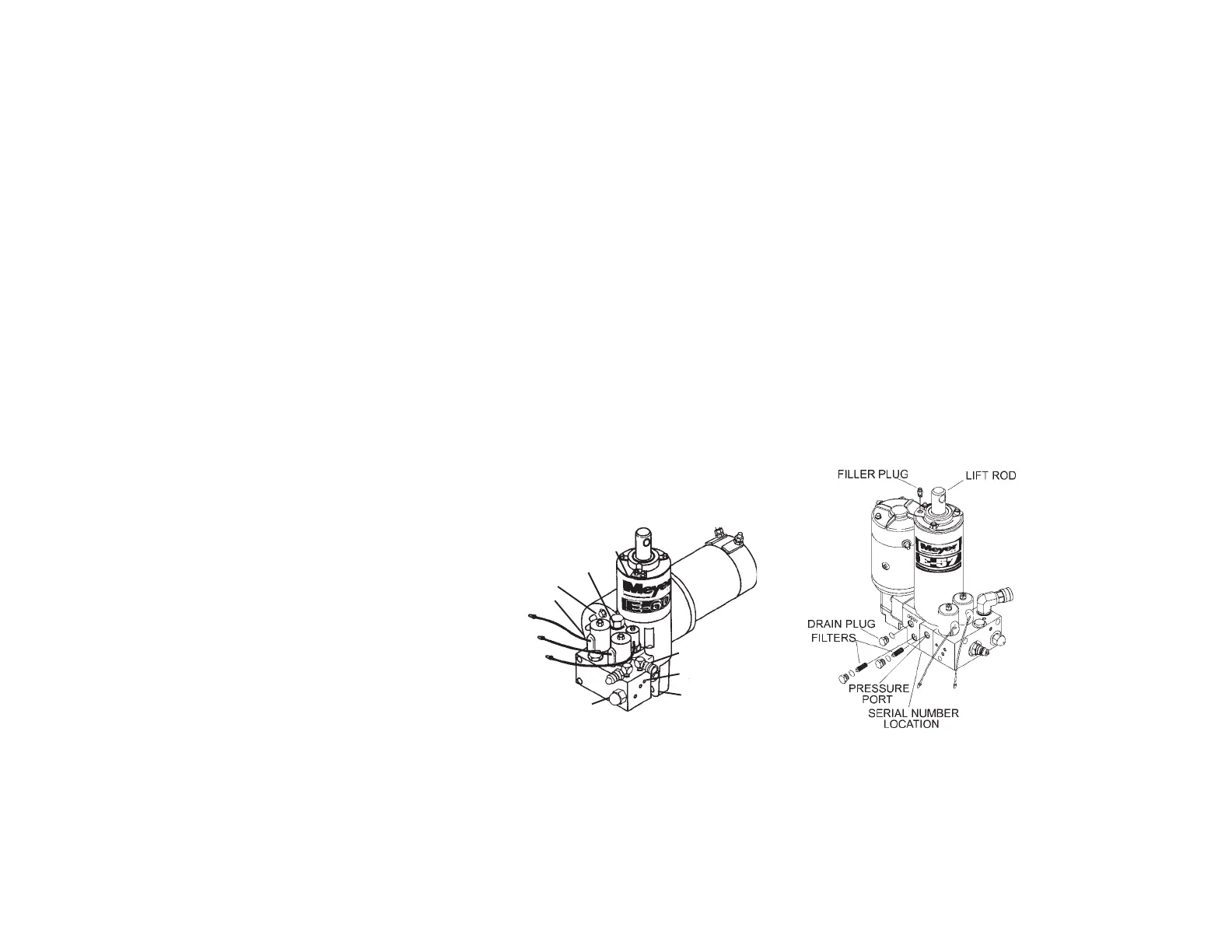

4. Refill power unit with Meyer Hydraulic Fluid M-1 by fully retracting

lift piston and filling reservoir to 1-1/2" below the filler hole. On

Power Angling models, fill and bleed hoses and Power Angling

cylinders by loosening hydraulic fittings at cylinders until they leak.

Power angle the plow repeatedly from one side to the other unit

fluid flows steadily from the fittings while maintaining a constant

check on the reservoir fluid level. The filling end of the cylinder

should be higher than the piston end to facilitate removal of air.

Raise and lower the plow several times. With lift rod fully retracted

check fluid level and replace filter plug.

SNOW PLOW STORAGE

1. When snow plow is disconnected,

extend lift cylinder to end of stroke

and coat chrome rod with light grease.

This fills the cylinder with hydraulic fluid

and protects the interior and exterior

from rust and corrosion.

2. Whenever Moldboard is disconnected,

coat the exposed portions of the power

angling cylinder chrome rods with light

grease to protect them from corrosion.

3. Be sure to reconnect quick couplers at

the P.A. Rams and plug in weather plugs

on Hydraulic Unit to keep them clean

and prevent contamination of the

system.

4. Coat all pivot pins and other wear points with chassis lubricant.

5. Unplug all electical connections at power unit. Coat all connections

with a dielectric compound to prevent corrosion and plug into their

corresponding weather plugs. Unplug the snow plow lights, tape or

use a dielectric compound at light connections to prevent

corrosion.

6. Remove EZ Mount® lift frame module from vehicle. Liberally coat

insides of clevis frame receiver tubes and ends of lift frame with

chassis grease/anti-seize lubricant. Protect clevis frame receiver

tubes from dirt and other types of contamination by installing the

receiver tube caps when the lift frame is removed from the vehicle.

7. WARNING: LIFT ARM EXTENDS BEYOND BUMPER OF

VEHICLE. TO MINIMIZE DAMAGE FROM A FRONT-END

COLLISION, LIFT ARM SHOULD BE REMOVED FROM VEHICLE

WHEN SNOW PLOW IS REMOVED.

FIGURE 0-3

20

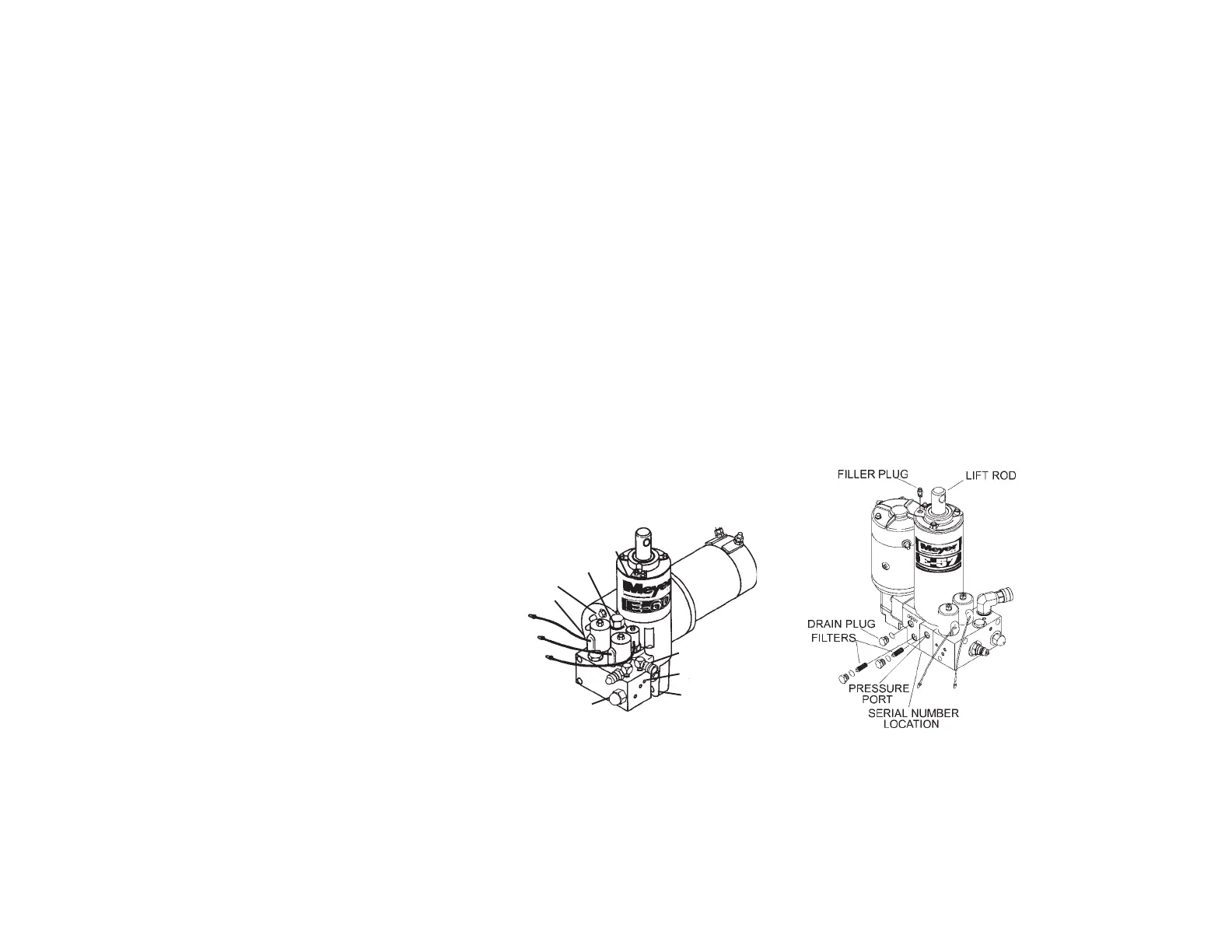

E-60

Cross-over Relief Valve

"C" Solenoid

(green wire)

"B" Solenoid

(red wire)

"A" Solenoid

(black wire)

Grounding Point

Pressure Relief Valve

Filler Hole and

Relief Valve

Right Angle

Lower

Adjustment

Angle Left

Motor

Filter Pressure Port

Loading...

Loading...