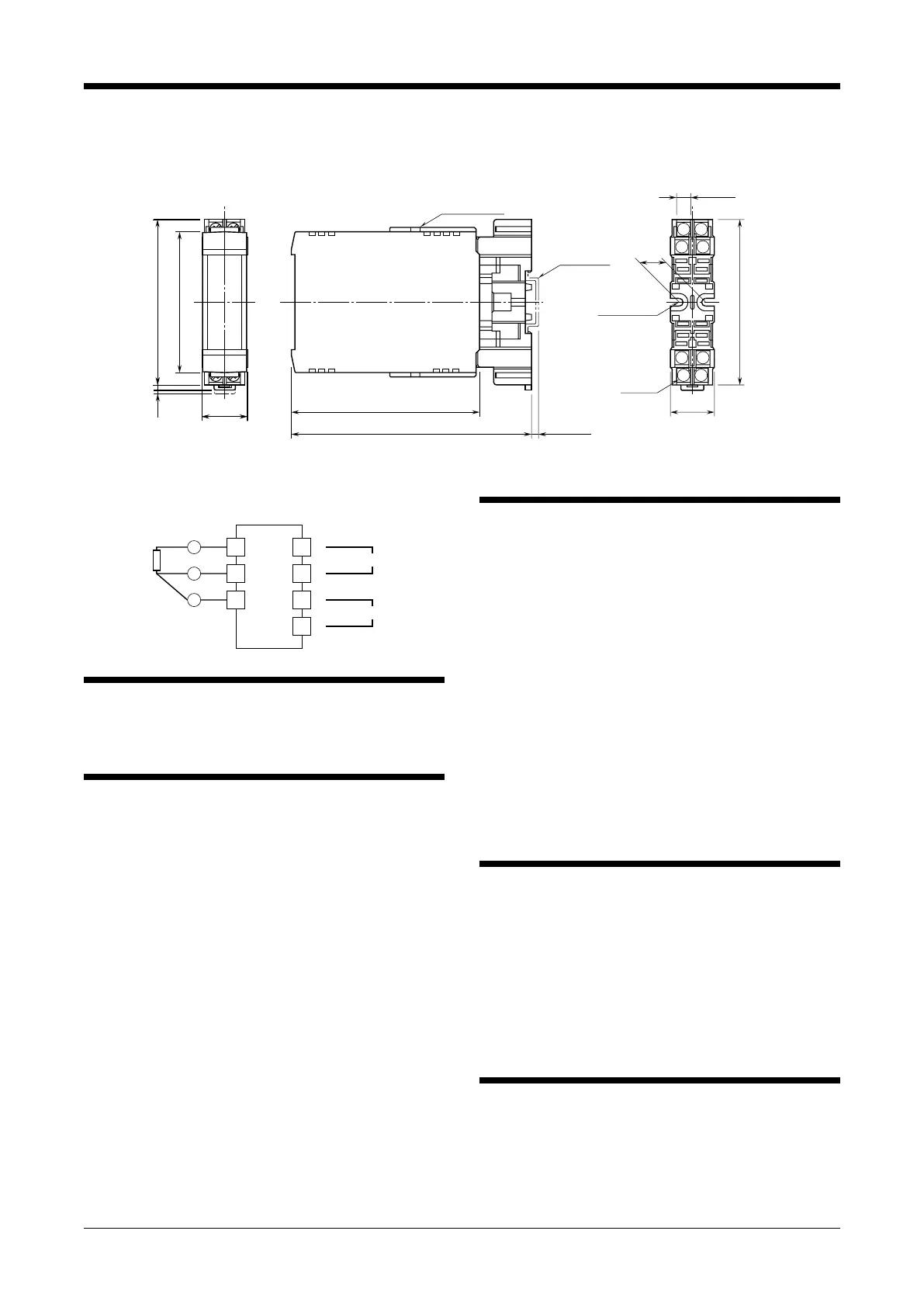

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the connection diagram on the side of the unit.

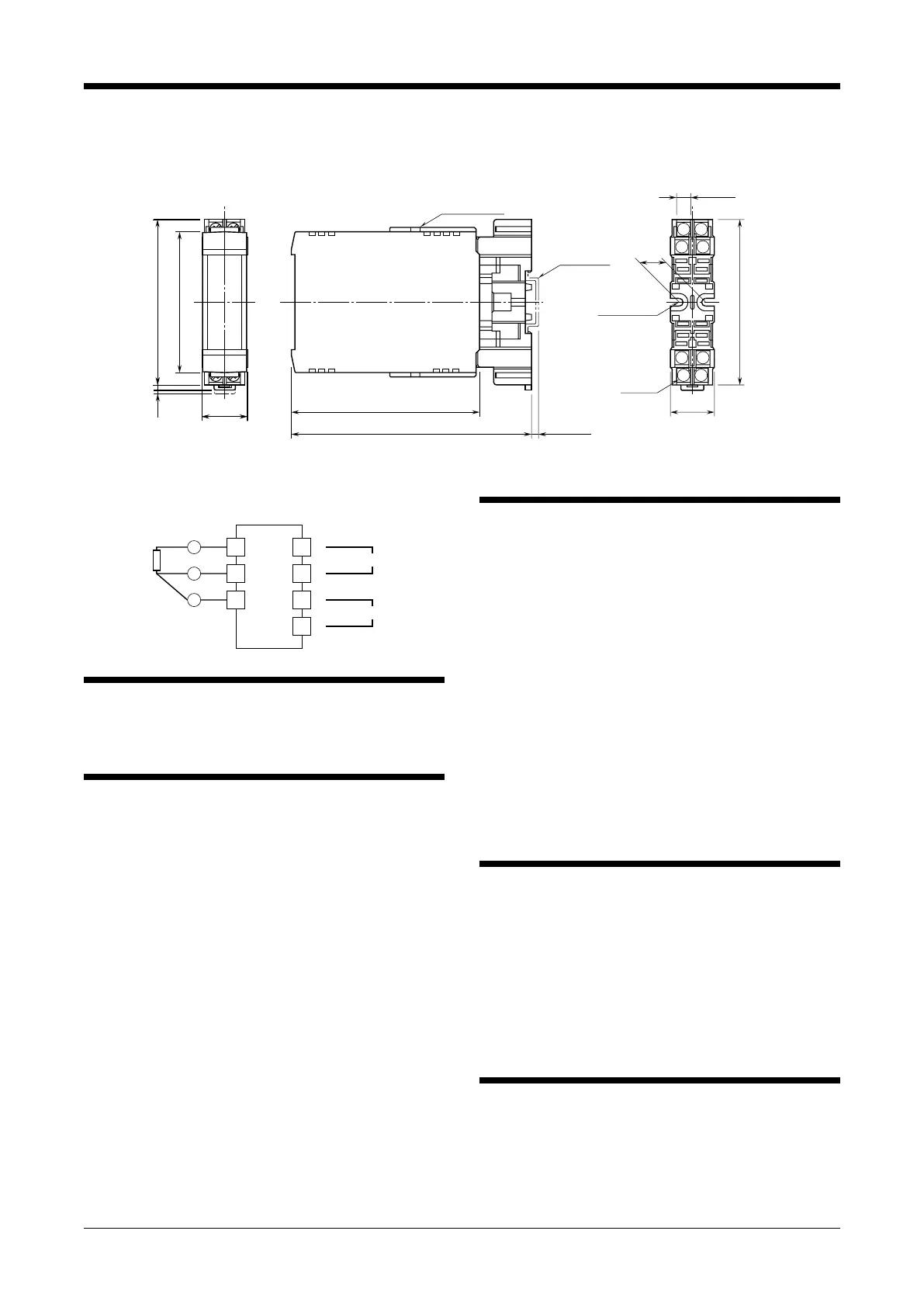

■ EXTERNAL DIMENSIONS unit: mm (inch)

12

34

7

6

8

5

3 (.12)2 (.08)

26 (1.02)

107 (4.21) 26 (1.02)

93 (3.66)

15

(.59)

2–4.5 (.18)

HOLE

15 (.59) deep

DIN RAIL

35mm wide

[3.3 (.13)]

8–M3.5

SCREW

93 (3.66)

CLAMP

(top & bottom)

137 (5.39)

80 (3.15)

•When mounting, no extra space is needed between units.

7.8 (.31)

■ CONNECTION DIAGRAM

+

–

OUTPUT

5

6

+

–

POWER

7

8

1

2

A

B

B

RTD

3

WIRING INSTRUCTIONS

■ SCREW TERMINAL

Torque: 0.8 N·m

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Input: Check voltage across the terminal 1 – 2 with a

sensitive voltmeter (With 20°C or 68°F, approx. 220mV

with Pt 100, approx. 110mV with Pt 50 Ω).

If RTD wires are broken, the output goes over 100% (be-

low 0% with downscale) due to burnout function. Check

leadwires in such a case.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration.

The output signal can be finely adjusted to match it to a re-

ceiving instrument, or to compensate input wire resistance

when the unit is combined with a zenor barrier. Follow the

regular calibration procedure explained below:

■ HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

LIGHTNING SURGE PROTECTION

We offer a series of lightning surge protector for protec-

tion against induced lightning surges. Please contact us to

choose appropriate models.

HR / HRS

EM-3413 Rev.5 P. 2 / 2

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Loading...

Loading...