4) Fully open the Handle Lo of the manifold

valve.

5) Turn on the vacuum pump to begin

evacuation.

6) Conduct a 30-minute evacuation. Check

whether the compound meter indicates

-0.1Mpa(14.5Psi). If the meter does not

indicate -0.1Mpa(14.5Psi) after 30 minutes

has elapsed, continue evacuation for 20

more minutes. If the pressure does not

reach -0.1Mpa(14.5Psi) after 50 minutes

has elapsed, check if there are any leaks.

Fully close the Handle Lo valve of the manifold

valve and turn off the vacuum pump. After 5

minutes, confirm that the gauge needle is not

moving.

7) Turn the flare nut on the 3-way valve45°

counterclockwise for 6-7 seconds. Once

gas begins to come out, tighten the flare nut.

Make sure the pressure display on the

pressure indicator is higher than

atmospheric pressure. Then remove the

charge hose from the 3-way valve.

8) Fully open the 2-wayand 3-way valves and

securely tighten the cap on the 3-way valve.

2. Air Purging Using Refrigerant

Procedure:

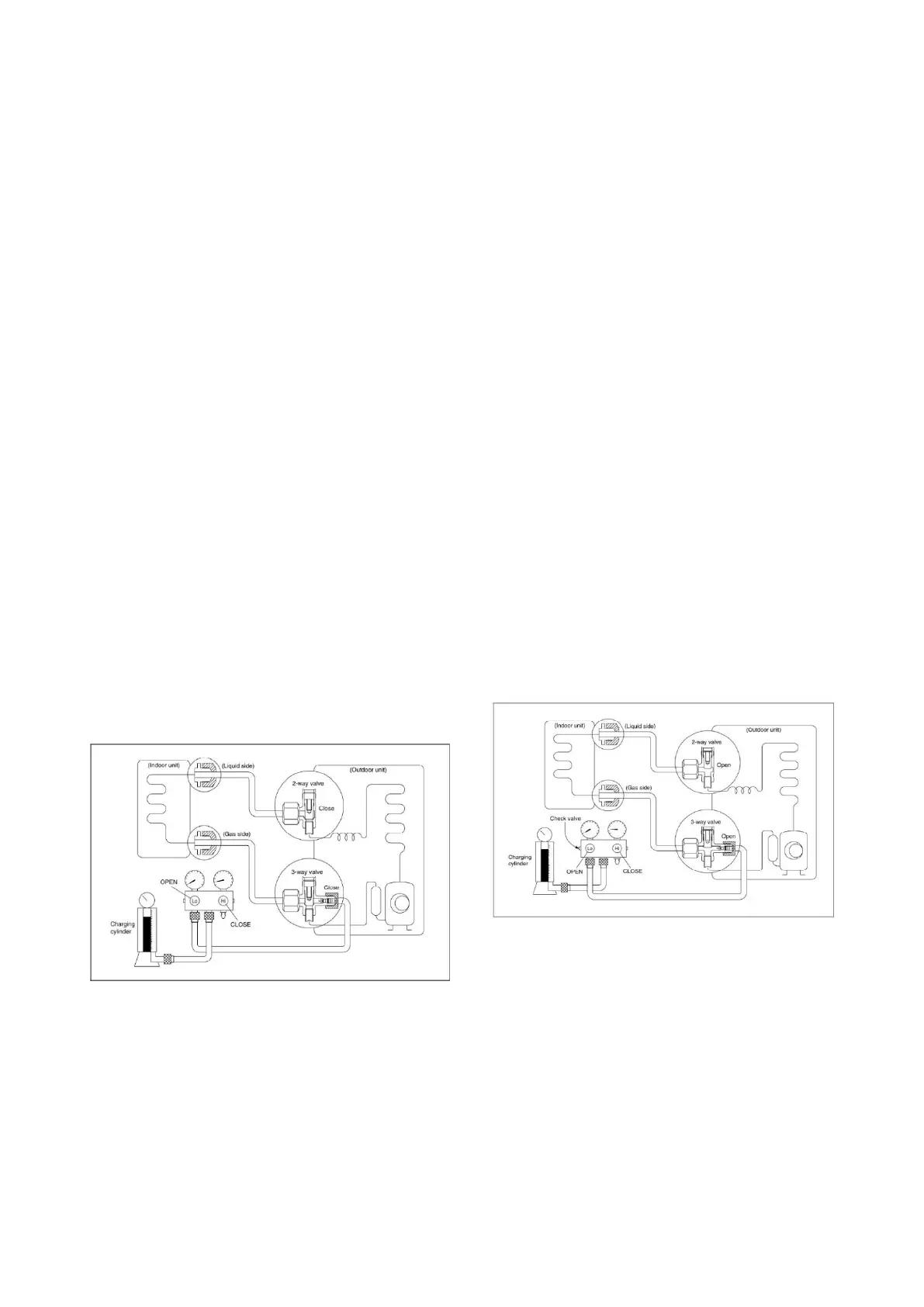

1). Confirm that both the 2-way and 3-way

valves are set to the closed position.

2). Connect the charge set and a charging

cylinder to the service port on the 3-way valve.

3). Air purging:

Open the valves on the charging cylinder and

the charge set. Loosen the flare nut on the

2-way valve approximately 45° for 3 seconds

then closing it for 1 minute. Repeat 3 times.

After purging the air, use a torque wrench to

tighten the flare nut on the 2-way valve.

4). Check for gas leaks.

Check the flare connections for gas leaks.

5). Discharge the refrigerant.

Close the valve on the charging cylinder and

discharge the refrigerant by loosening the flare

nut on the 2-way valve approximately 45° until

the gauge displays a value between 0.3 to 0.5

Mpa(43.5 to 72.5Psi)

6). Disconnect the charge set and the charging

cylinder. Set the 2-way and 3-way valves to the

open position.

Be sure to use a hexagonal wrench to open and

close the valve stems.

7). Mount the valve stems nuts and the service

port cap.

Be sure to use a torque wrench to tighten the

service port cap to a torque of 18N·m.

Be sure to check for gas leaks.

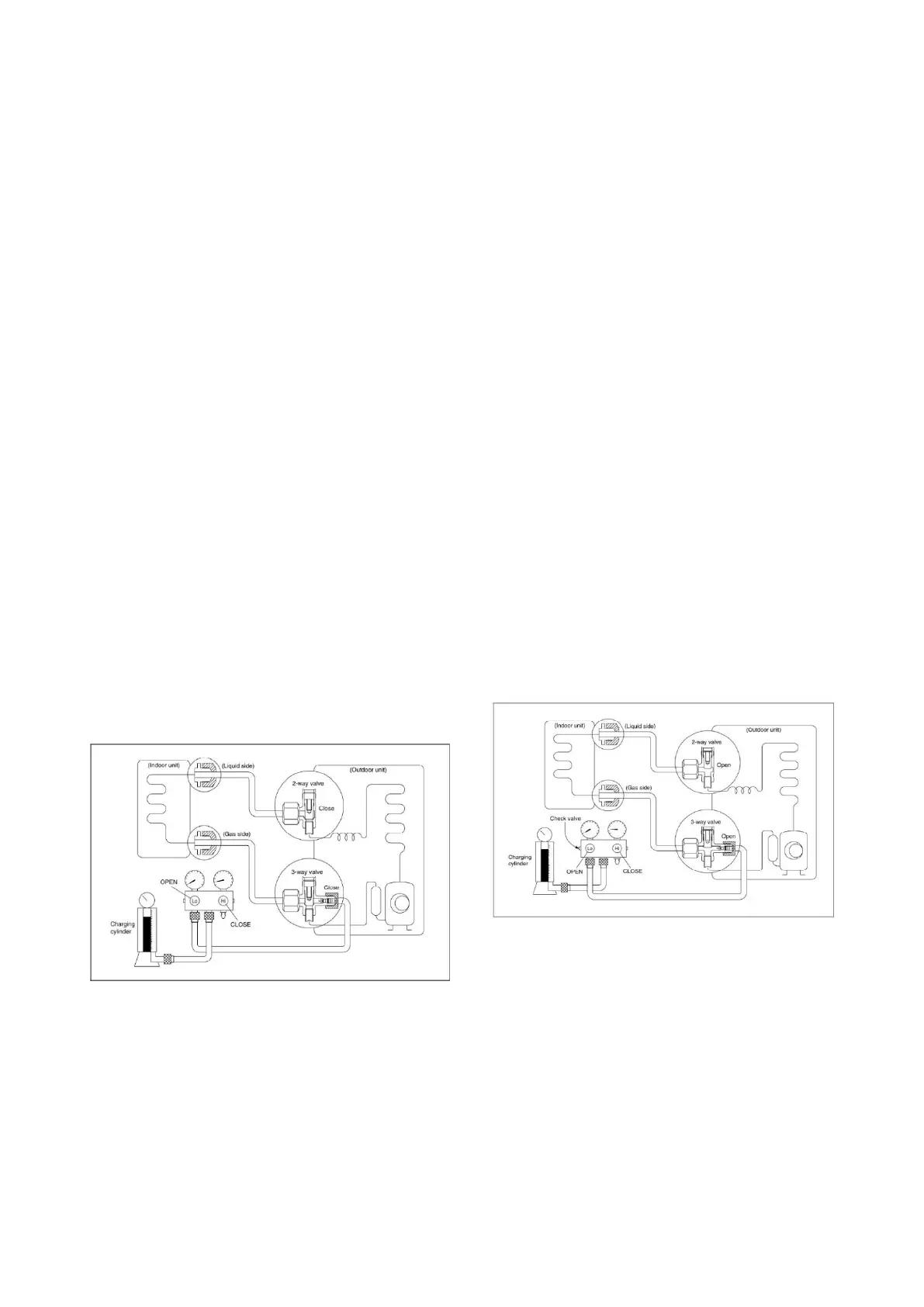

14.4.4 Adding Refrigerant after Long-Term

System Operation

Procedure

1). Connect the charge hose to the 3-way

service port and open the 2-way and 3-way

valve.

Connect the charge hose to the valve at the

bottom of the cylinder. If the refrigerant is

R410A, place the cylinder bottom-up to ensure

liquid charge.

2). Purge the air from the charge hose.

Open the valve at the bottom of the cylinder

and press the check valve on the charge set to

Loading...

Loading...