VC Pro VRF 50/60Hz

166

Midea VC Pro Series Engineering Data Book

5.5 Brazing

Care must be taken to prevent oxide forming on the inside of copper piping during brazing. The presence of oxide in a

refrigerant system adversely affects the operation of valves and compressors, potentially leading to low efficiency or even

compressor failure. To prevent oxidation, during brazing nitrogen should be flowed through the refrigerant piping.

Box continued on next page …

Warning

Never flow oxygen through piping as doing so aids oxidation and could easily lead to explosion and as such is

extremely dangerous.

Take appropriate safety precautions such as having a fire extinguisher to hand whilst brazing.

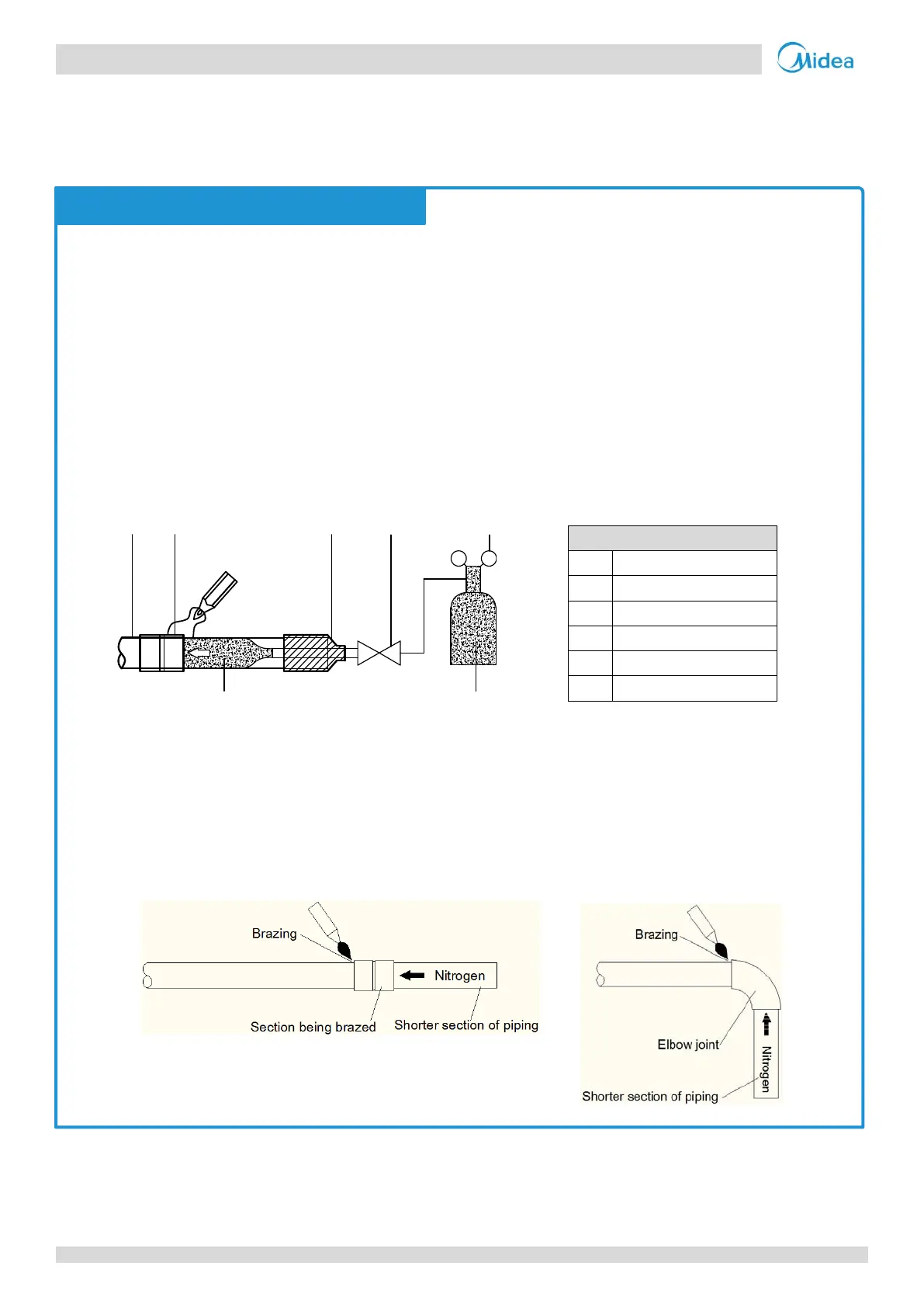

Flowing nitrogen during brazing

Use a pressure reducing valve to flow nitrogen through copper piping at 0.02-0.03MPa during brazing.

Start the flow before brazing starts and ensure that the nitrogen continuously passes through the section being

brazed until the brazing is complete and the copper has cooled down completely.

Figure 3-5.4: Flowing nitrogen through piping during brazing

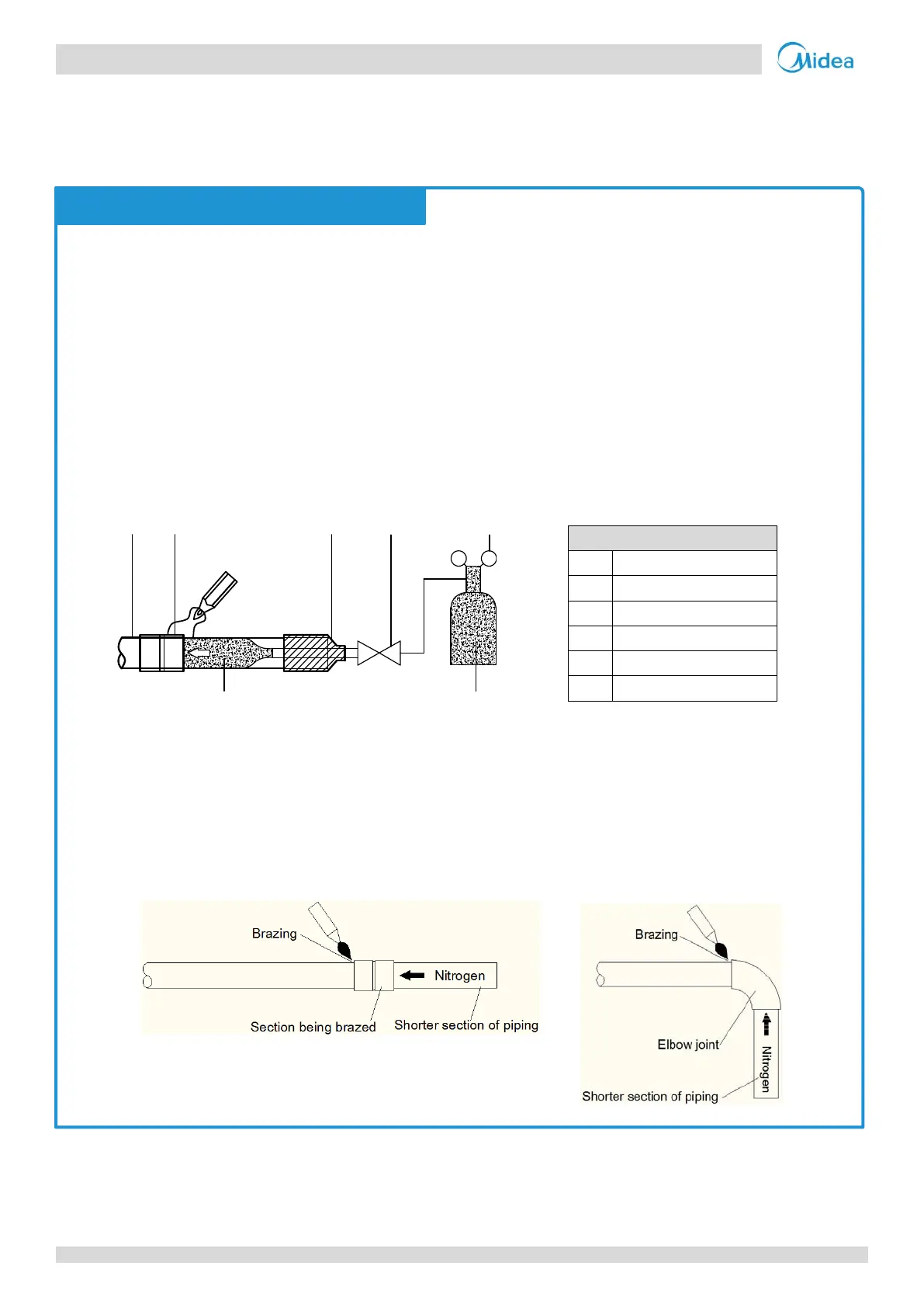

When joining a shorter section of piping to a longer section, flow nitrogen from the shorter side to allow better

displacement of air with nitrogen.

If the distance from the point where nitrogen enters the piping to the joint to be brazed is long, ensure that the

nitrogen is flowed for sufficient time to discharge all the air from the section to be brazed before commencing

brazing.

Figure 3-5.5: Flowing nitrogen from shorter side during brazing

Loading...

Loading...