Midea

V6R

Series Engineering Data Book

5.8.2 Procedure

Box continued on next page …

Warning

Only use nitrogen for flushing. Using carbon dioxide risks leaving condensation in the piping. Oxygen, air, refrigerant,

flammable gases and toxic gases must not be used for flushing. Use of such gases may result in fire or explosion.

Procedure

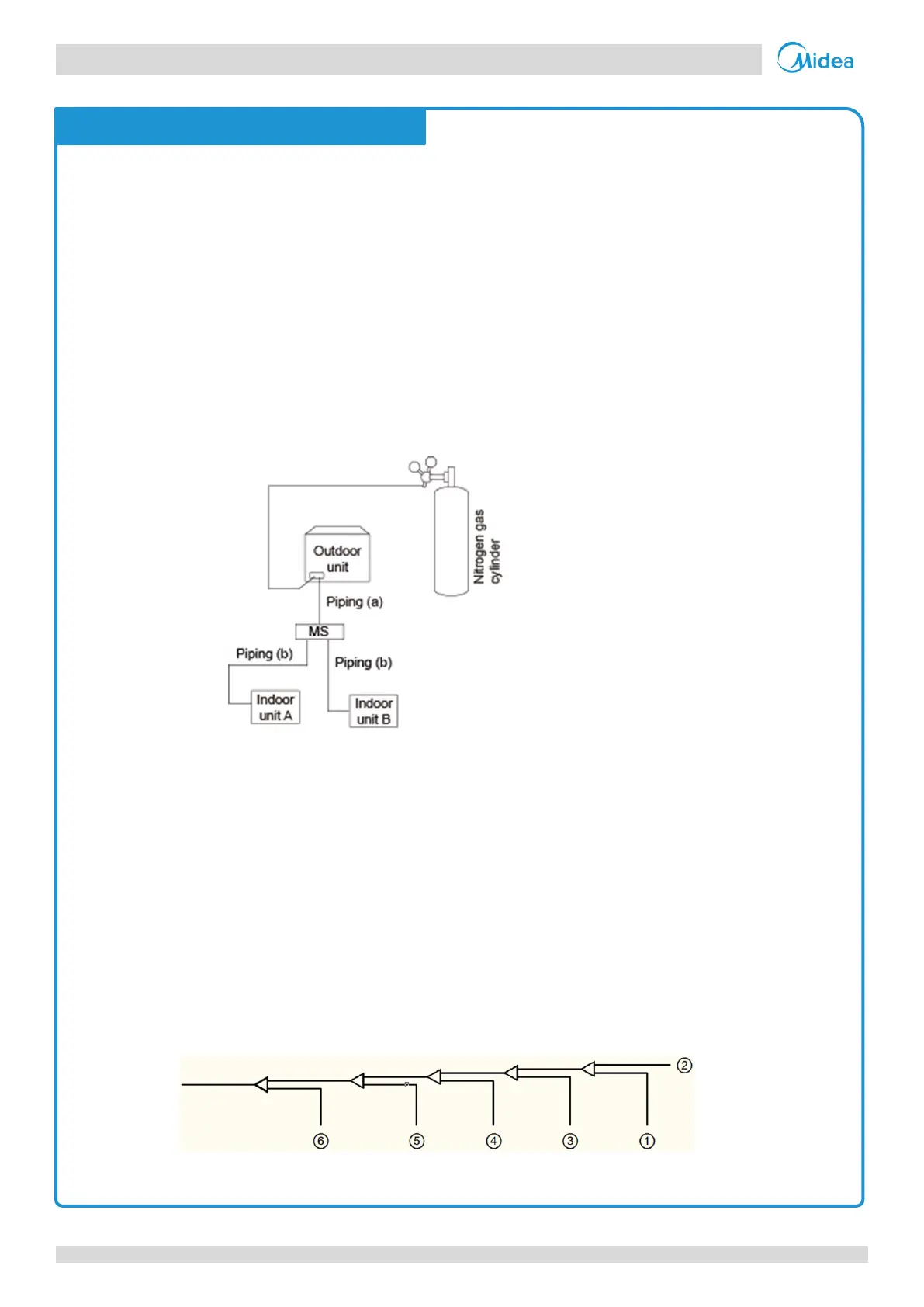

1. Braze the refrigerant piping and branch joints between outdoor unit(s) and MS box (piping (a) in Fig. 5-16), but not

connect piping (a) to MS box.

2. Flush piping (a) with nitrogen, and then connect piping (a) to MS box according to the description of 5.4.8.

3. Braze the refrigerant piping and branch joints between MS and indoor units (piping (b) in Figure 5.16), but not

connect piping (b) to MS box.

4. Flush piping (b) with nitrogen, and then connect piping (b) to MS box according to the description of 5.4.8.

5. Flush all refrigerant piping from outdoor unit stop valves to ensure no impurities remained. Flus

h piping (a) with nitrogen,

Pipe Flush Procedure

The liquid and gas sides can be flushed simultaneously; alternatively, one side can be flushed first and then Steps 1 to

8 repeated, for the other side. The flushing procedure is as follows:

1.

Cover the inlets and outlets of the indoor units to prevent dirt getting blown in during pipe flushing. (Pipe flushing

should be carried out before connecting the indoor units to the piping system.)

2. Attach a pressure reducing valve to a nitrogen cylinder.

3. Connect the pressure reducing valve outlet to the inlet on the liquid (or gas) side of the outdoor unit.

4.

Use blind plugs to block all liquid (gas) side openings, except for the opening at the indoor unit which is furthest

from the outdoor units (“Indoor unit A” in Figure 3-5.11).

5. Start to open the nitrogen cylinder valve and gradually increase the pressure to 0.5MPa.

6. Allow time for nitrogen to flow as far as the opening at indoor unit A.

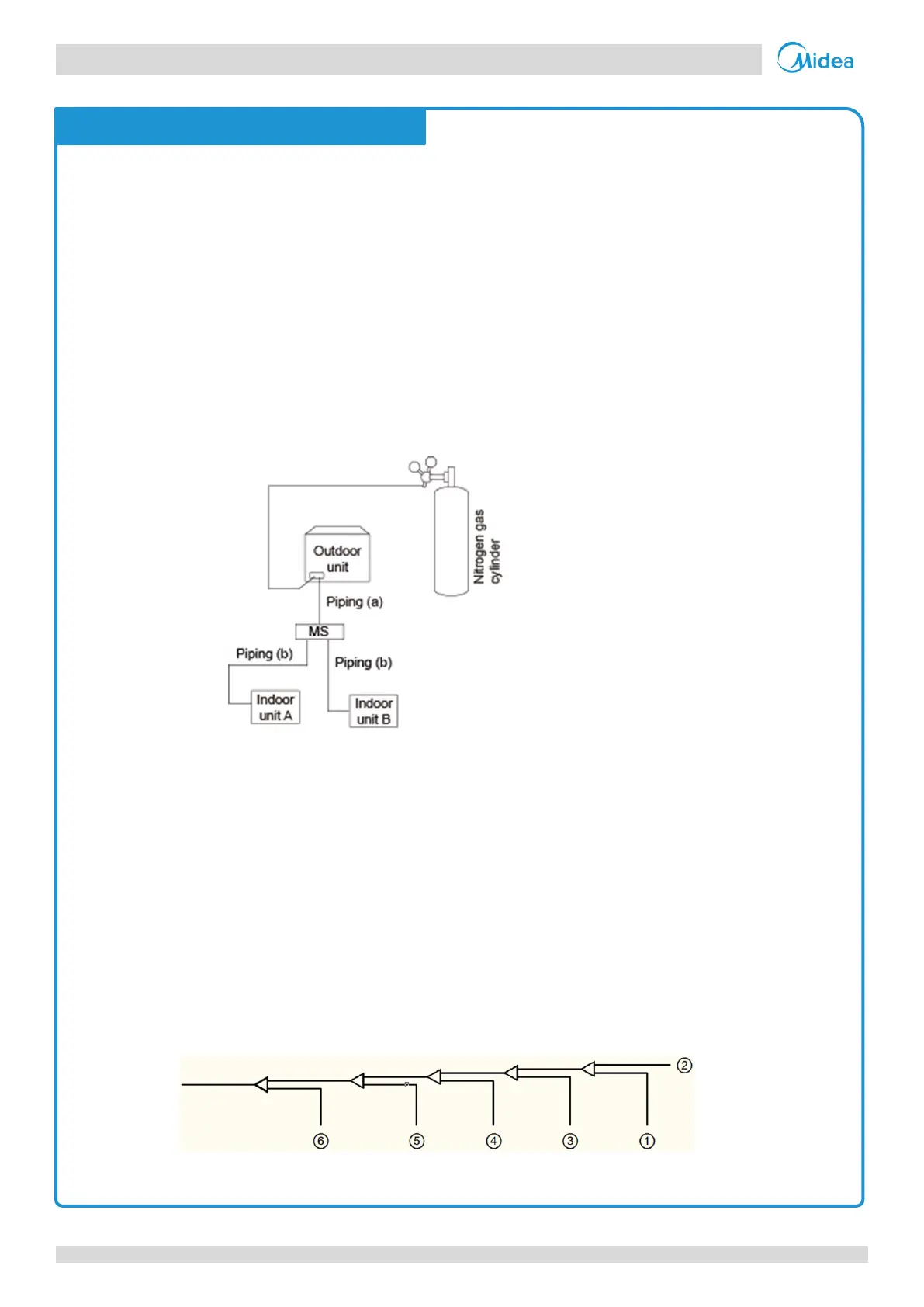

Figure 3-5.12: Pipe flushing sequence

1

Notes:

1. 1-2-3-4-5-6 working towards the MS box

Figure 3-5.11: Pipe flushing using nitrogen

Loading...

Loading...