8. TECHNICAL SPECIFICATIONS

8.1 GENERAL

CONSTRUCTION: Stainless steel 18/10, DIN 1.4301 (AISI 304) for inner and outer tank vessel.

TANK TYPE: Vertical type cylindrical tank, free standing, smooth inner sides, rounded angles, perfectly polished welding, ad-

justable legs for uneven floors. Direct expansion bottom designed to ensure total drain of tank. The design of evaporator plates

prevents milk freezing even at low milk volumes. Crash test at 60BAR. Function pressure: 30BAR. Fine insulation precisely

controlled infusion of high – density environment friendly polyurethane foam. 30rpm (90W) single-phase agitator motor for

IC 50 – 1200liters, 30rpm (120W) single-phase agitator motor for IC 1500 – 2000liters , stainless steel lid without any screws

inside and one-piece agitator (without joints). Automatic stop of the agitation motor in case the lid opens. Milk inlet 180mm

and stainless steel cover. Elevated parts (opening handle, stirring motor and electrical control panel) for easy cleaning. Milk

outlet and milk cooling tank evaporator plate inclination according to the international standards (ISO 5708). Stainless steel

springs for easy opening and closing of the milk cooling tank lid (for IC 200 – 2500 liters). Stainless steel dipstick and standard

calibration chart. IP55 panel for electric instrument (Applicable Standard: EN 60529/91, Applicable directives: LVT 73/23/EEC).

Stainless steel 2” sanitary fitting to accommodate user-specified output valve. Perforated stainless steel condensing unit cover

with removable sides for easy maintenance and for the condensing unit ventilation – protection (Patent No. : 1004080) for IC

50lt-1000lt.

CONDENSING UNIT: Close type condensing unit compressor by L’Unite Hermetique, coolant type R404A (full ecological).

A solenoid valve, high pressure switch, low pressure switch, high pressure switch for the second run regulation (Models IC

1000-2500lt) on the refrigerating circuit) protect the condensing unit and improve its performance.

INSULATION TYPE: INTERVOL RFN-24. Two components polyurethane rigid foam system. Blowing agent used is HCFC-141b

(CFC – free system). Thickness: 45mm. Density: 40kg/m

3

(DIN53420). Compressive strength: 20kPa (DIN53421). Thermal con-

ductivity, 24C: 0.023 W/m K (DIN18164).

PANEL FOR ELECTRIC INSTRUMENT: PROTECTION CLASS: IP 55 class-standard (Applicable Standard: EN 60529/91, Applicable

directives: LVT 73/23/EEC). TYPE: Tank mounted.

MILK CONTROLLER - THERMOSTAT: OPERATING TEMPERATURE: +0 +60C. STORAGE TEMPERATURE: -30 +85C. POWER

SUPPLY: 230V – 50Hz 10%. POWER ABSORPTION: 3VA max. MANUFACTURER: DIXELL SRL, ITALY. FUNCTION: When the com-

pressor reaches the set point, it stops its function and the auto agitation of milk begins for 15minutes pause, 3 minutes agita-

tion and so on until the milk temperature SET+ Hy when the compressor starts again. In case of probe failure , the output is

according to parameter “COn” - Compressor ON time with faulty probe (range: 0 255min, val.15min) and “COF” ” - Compres-

sor OFF time with faulty probe (range: 0 255min, val.30min). Note: All of the milk controller parameters are adjustable.

DIPSTICK: High precision stainless steel dipstick (AISI 304) for easy and direct volume reading in mm.

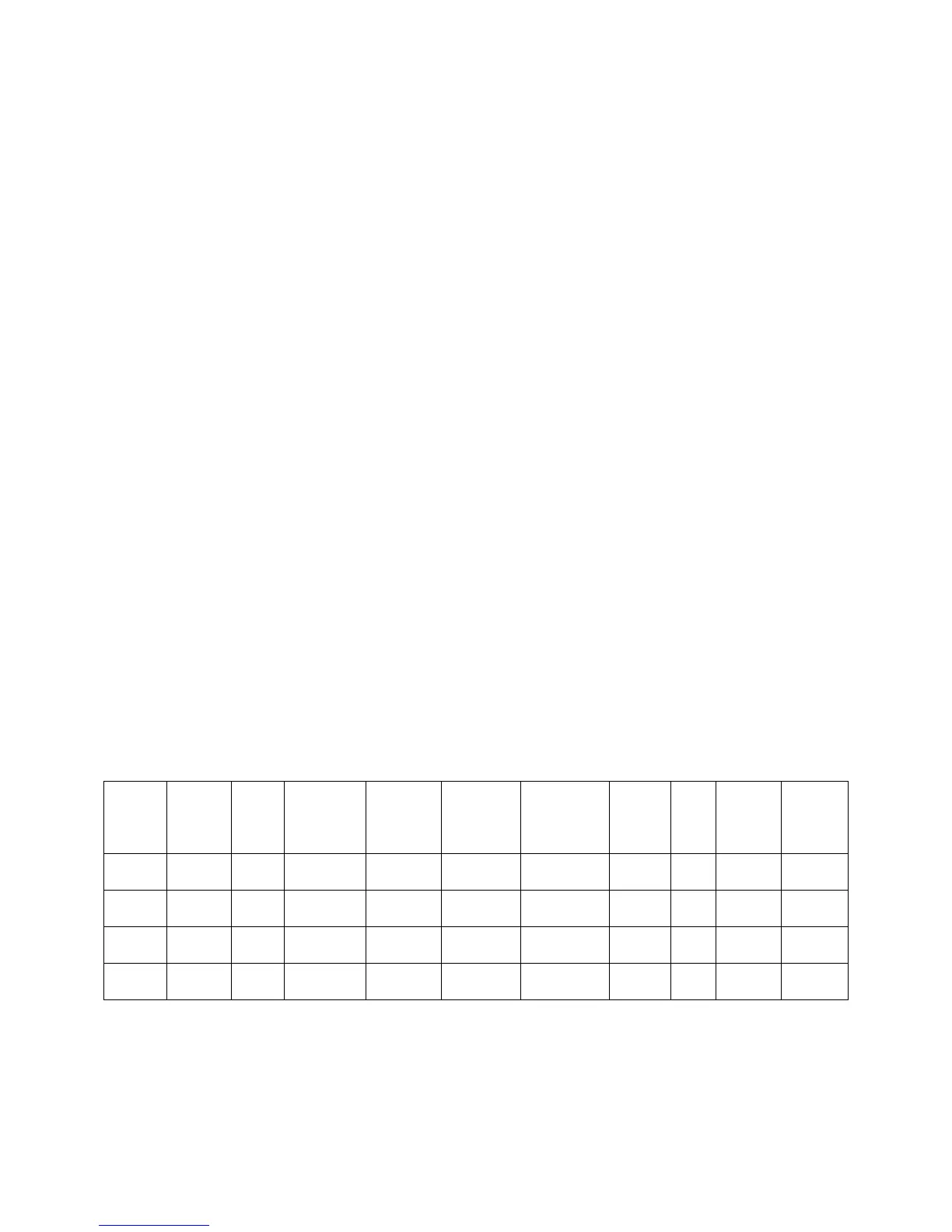

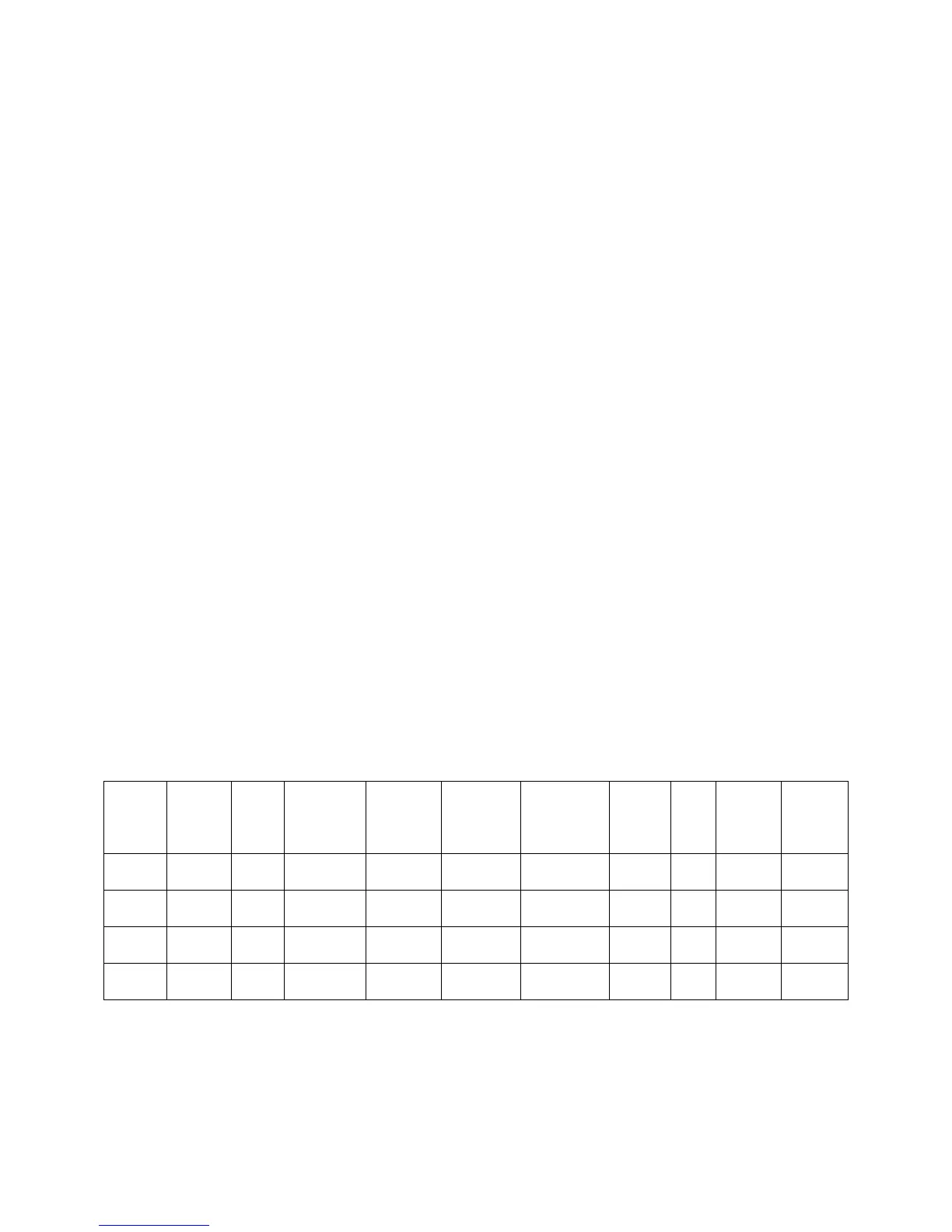

8.2 POWER SPECIFICATIONS

(Note: Other tank sizes, voltages and capacities are available.)

Loading...

Loading...