Motor Preventive Maintenance

PELLERIN MILNOR CORPORATION

12,000 x 0.5 = 6,000 hours

Where:

12,000 is the standard lubrication interval

0.5 is the severity of service multiplier

5. Determine from Table 3, the amount of grease to apply to the motor bearings, based on the

frame size range. Adjust for a smaller bearing size if necessary. Example based on above:

Grease volume = 0.16 ounces (4.7 grams)

Grease gun strokes = 2.5

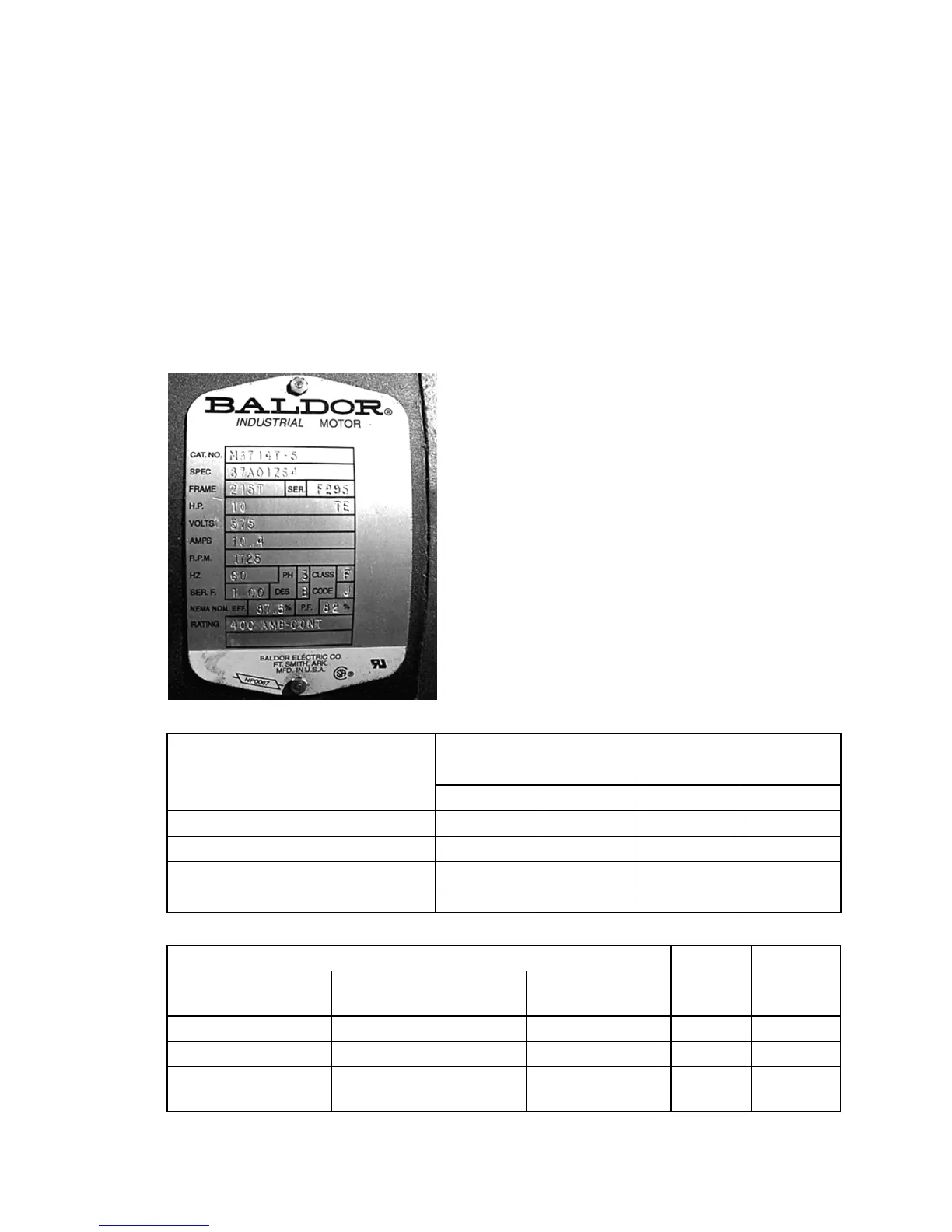

Figure 1: Typical Motor Data Plate

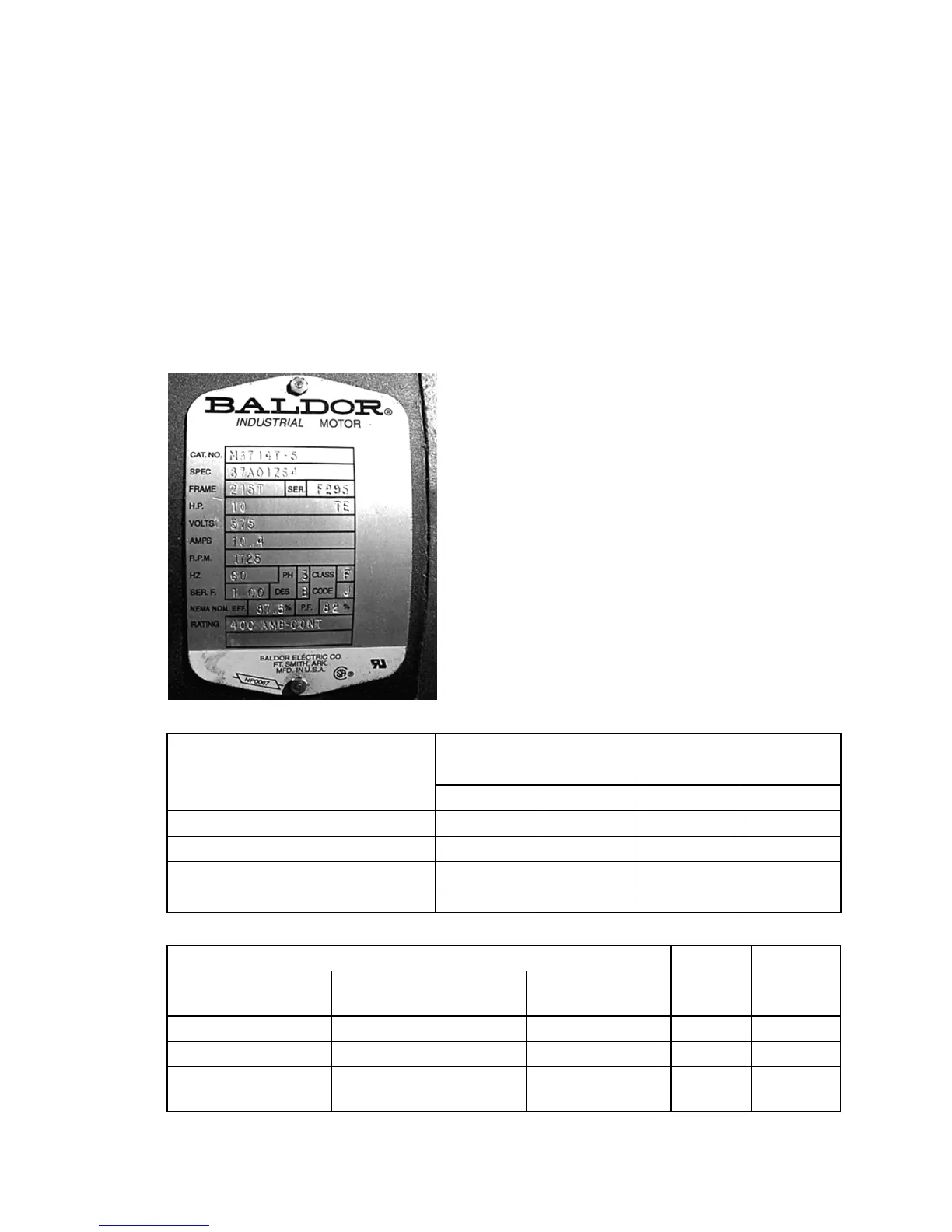

Table 1: Lubrication Interval for Standard Severity of Service

Same or Closest Higher RPM Rating

NEMA (IEC)

Frame Size Range

3600 RPM 1800 RPM 1200 RPM 900 RPM

Up to 215 (132) 5500 hours 12000 hours 18000 hours 22000 hours

254 to 286 (160 - 180) 3600 hours 9500 hours 15000 hours 18000 hours

324 to 365 (200 - 225) 2200 hours 7400 hours 12000 hours 15000 hours

6313 or 6314 bearings 2200 hours 3500 hours 7400 hours 10500 hours

404 to 5000

(280 - 315)

roller bearings 1100 hours 1750 hours 3700 hours 5250 hours

Table 2: Determining the Service Severity Rating and Multiplier

Considerations (any non-"Standard" condition raises rating)

Maximum Ambient

Temperature

Or Atmospheric

Contamination

Or Bearing Type

Service

Severity

Rating

Multiplier

104°F (40°C) Clean, little corrosion Deep groove ball Standard 1.0

122°F (50°C) Moderate dirt, corrosion Ball thrust, roller Severe 0.5

>122°F (>50°C)

Much dirt, abrasive

dust, corrosion

n.a. Extreme 0.1

Loading...

Loading...