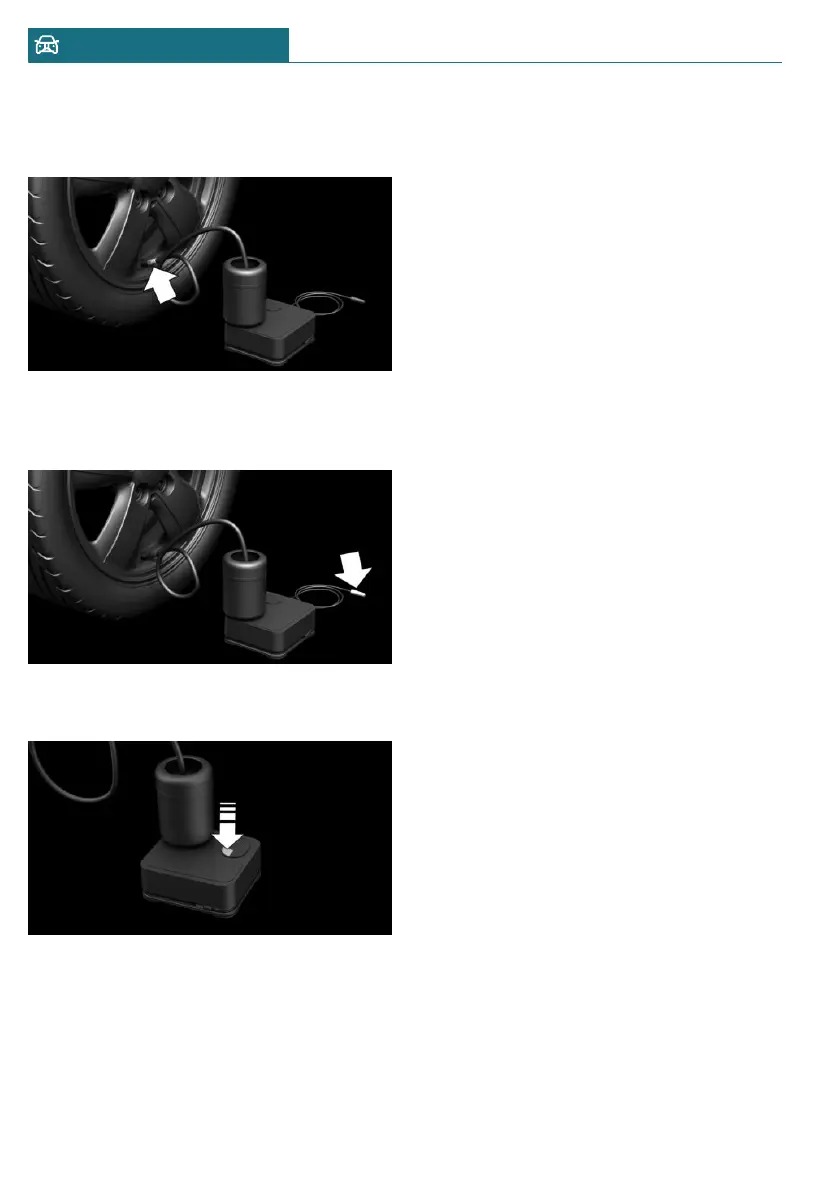

4. Screw the filler hose of the sealant bot-

tle onto the tire valve of the faulty

wheel.

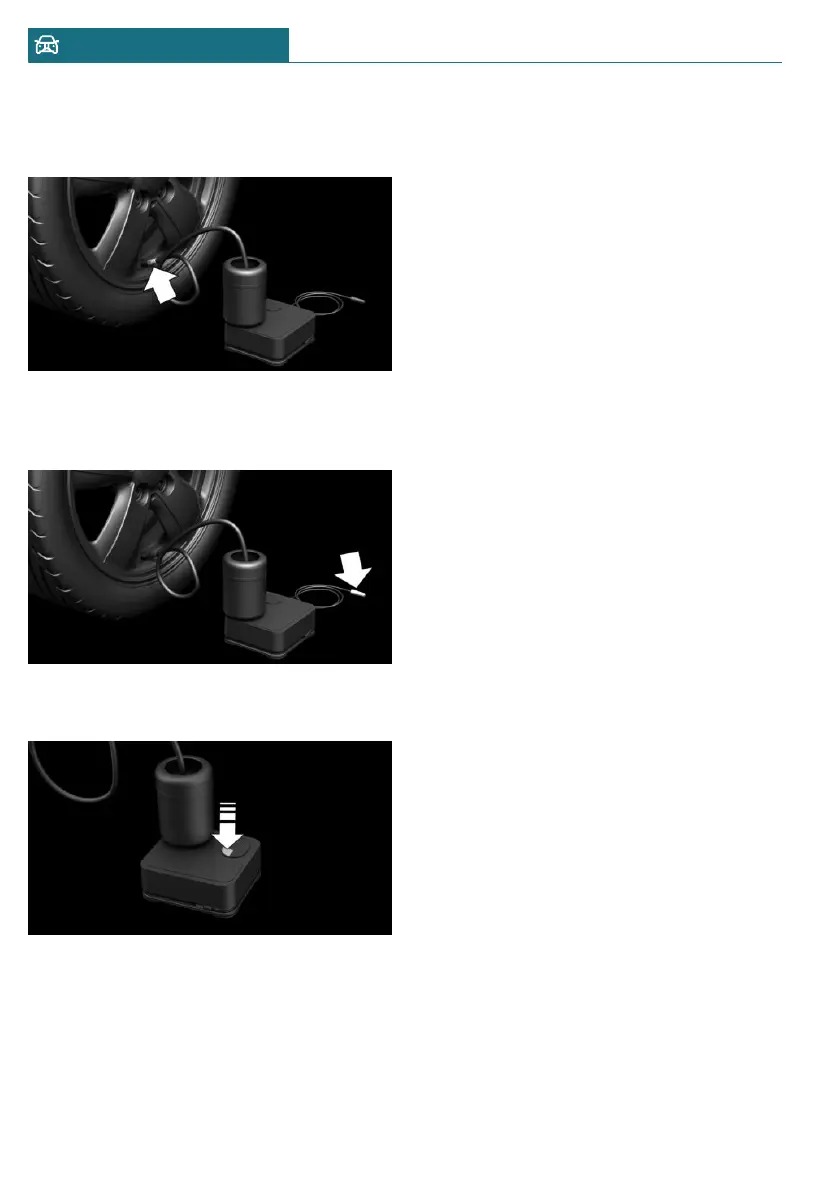

5. With the compressor switched off, in-

sert the connector into the power socket

in the vehicle interior.

6. With the ignition switched on or the en-

gine running, switch on the compressor.

Let the compressor run for max. 10 mi-

nutes to fill the tire with sealing compound

and achieve a tire inflation pressure of ap-

prox. 2.5 bar.

While the tire is being filled with sealing

compound, the tire inflation pressure may

sporadically reach approx. 5 bar. Do not

switch off the compressor in this phase.

Checking and adjusting the tire

inflation pressure

Checking

1. Switch off the compressor.

2. Read the tire pressure on the tire pres-

sure display.

To continue the trip, a tire inflation pres-

sure of at least 2 bar must be reached.

Removing and stowing the sealant

bottle

1. Unscrew the filler hose of the sealant

bottle from the tire valve.

2. Press the red unlocking device.

3. Remove the sealant bottle from the com-

pressor.

4. Wrap and store the sealant bottle in

suitable material to avoid contamination

of the cargo area.

Minimum tire inflation pressure is not

reached

1. Pull the connector out of the power

socket in the vehicle interior.

2. Drive 33 ft/10 m forward and back to

distribute the sealing compound in the

tire.

Seite 262

MOBILITY Wheels and tires

262

Online Edition for Part no. 01405A53AA0 - II/22

Loading...

Loading...