INTRODUCTION

ThemachineissuppliedwithAC220Vinput.It’susingadvancedinverter

technologytotransfer50/60HZpowerfrequencyelectrictoabove100KHZhigh

frequencyelectricthroughtheinvertercombinedwithpowerfulcomponentssuchas

MOSFETandsoon.Thenaftervoltagereducing-rectifying-wavefilteringitalsoadopts

pulse-widthmodulation(PWM)andclosed-loopbackcircuitcontroltechnologyto

outputstableDCcurrent.Thusthisunithasthefollowingcharacteristics:highefficiency,

lowenergyconsumption,compact,gooddynamiccharacteristics,stablearc,

continuousadjustablecurrentandsoon.Alsoit’swithprotectionfunctionfor

overvoltage,overcurrentandoverheattoensurethesafetyanddurabilityofthewelder.

Thewelderisofconstantcurrentcharacteristics,andweldingcurrentis

stableanddoesn'tchangewiththearc.Andincuttingprocess,thetemperature

canreach10000-15000

afterthearciscompressedbyhigh-speedflowingair,then

themachineentersintohighionizationstateandgetspowerfulplasmaarc.

Theunitiswithfootpedalconncetorwhichisforremotecurrentcontrol

andmoreconvenientforoperation.Andit'swidelyusedinaluminum,carbon

steel,stainlesssteel,cooperandtitaniumwelding,etc.

Welcometopurchasingourproductandgivingusmorevaluableadvice.Andwe

willbecommittedtoperfectproductsandservicestocreatethetopbrandamongthe

weldingindustry.

1.

Creepage-protectingswitchshouldbeusedwhenyouoperatethemachine!

2.

Withinindoorenvironmentthemachinemayproduceradiowave,sotheuser

shouldmakefullofpreventivemeasures.

3.

Pleasemakesurethepowersupplyiscutoffbeforeanyconnectingoperation.

4.

Ifdistancebetweenwork-pieceandmachineistoofar(

50m),andwelding

cablesaretoolong,pleaseselectthecablewithbiggersectiontoreducethe

voltagedropping.

SUPERSeries·User’sManual

-14-

SOLUTIONTOFAULT

Belowphenomenonisrelatedtofittings,weldingmaterials,environmentfactor,

supplypowers,pleasetrytoimprovetheweldingenvironment.

1.Currentisunstableduringweldingprocessanditmaybecaused

bythefollowings

1.1Electricnetworkvoltagechanges.

1.2Harmfulinterferencesfromelectricnetworkorotherequipments.

1.3Undersizeofexternalinputcable.

2.Outputcurrentnotuptoratedvalue

Currentwillnotmatchthesettingvaluewhenpowervoltagedepartsfromtherated

value.Whilevoltageislowerthantheratedvalue,themaxoutputmaybelowerthan

theratedvalue.

3.Arc-strikingdifficultandeasilypausesunderMMAorTIG

3.1Makesuretherodortungstenisofgoodqualityotherwiseitisdifficulttomeetthe

requestofthehighqualitywelding.

3.2Itwillbehardtostrikearciftherodisnotdryenoughorthetungstenisnot

sharpened.Itwillalsocauseunstablearcandtheweldingqualitywillbe

influencedbyincreaseddefect.

4.ToomuchspatterunderMMAwelding

4.1Highcurrentwithrodofsmalldiameter.

4.2Theoutputterminalpolarityisreversed.Fornormaluseyoucanadoptpositive

connectionwhichmeanstheholderconnectsto“-”polarityandwork-piecetothe

“+”polarity,sopleaseexchange.

5.Unsmoothcuttingappearanceandunsatisfactorycuttingeffect

5.1 Make sure the compressed air source is stable and with enough pressure.

Normallytheairpressureshouldbenotlessthan0.3Mpa(around3Kgf/cm²),and

therangeoffluctuationshouldbeunder±0.05Mpa.

5.2Theelectrodeandtipdiameterdonotmatchthecuttingcurrentverywell.

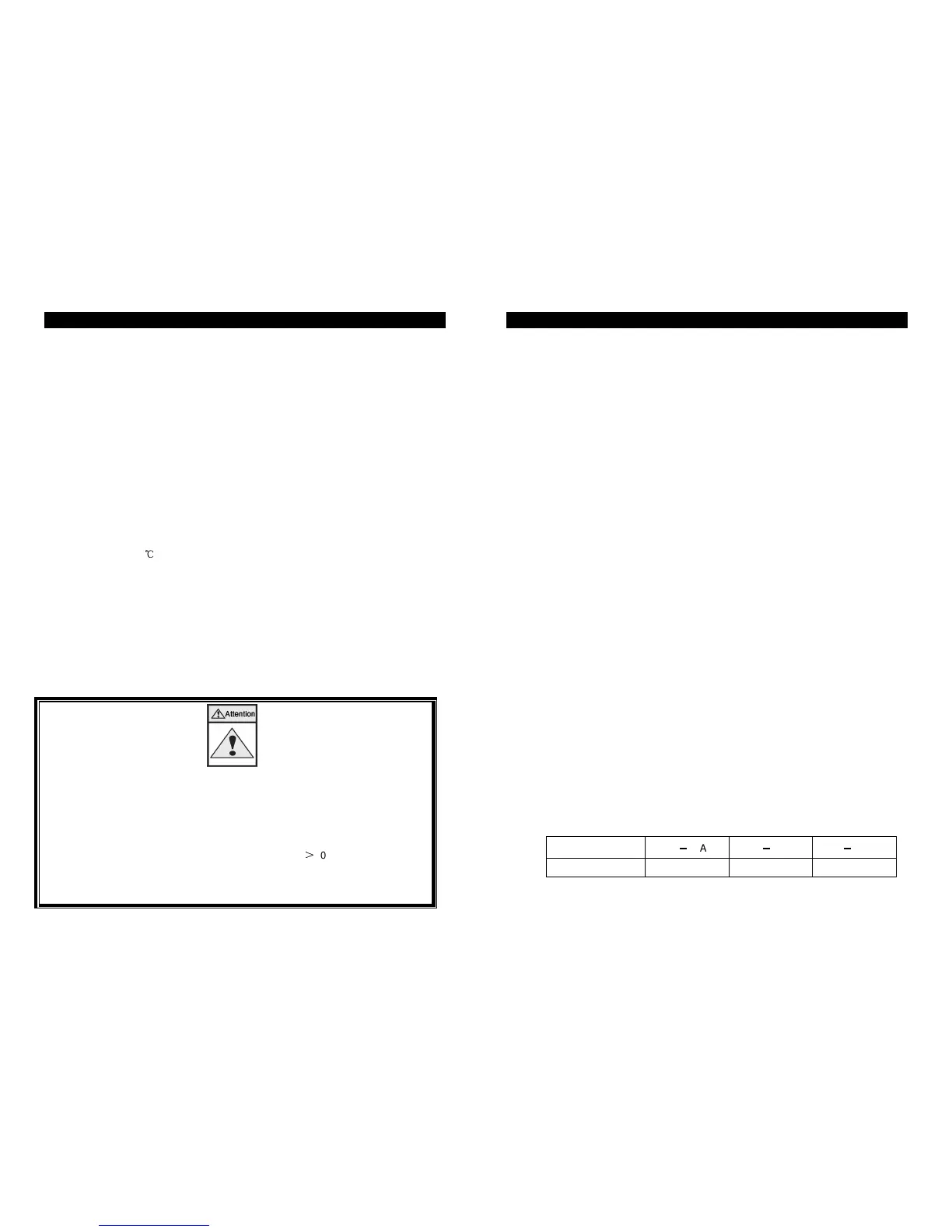

Tipstandard

Currentrange 10

30A 30

40A 60

100A

Tipdiameter 1.0mm 1.2mm 1.3mm

Loading...

Loading...