ENGINE

(8) Insert

the

tappets, each

tappet

being com-

plete with shim.

Be

sure

that

guide pin

holes in

tappet

and

pump

housing are

aligned. Attach lock plate and,

through

the

plate, insert guide pin. After installing the

guide pins, lock the pins by bending

the

plate sharply.

Installing

tappet

(9) Install the smoke-set device, positioning its

return spring and washer correctly, and

lock it by inserting split pin.

(10) Adjust and set the reassembled injection

pump

in the following manner:

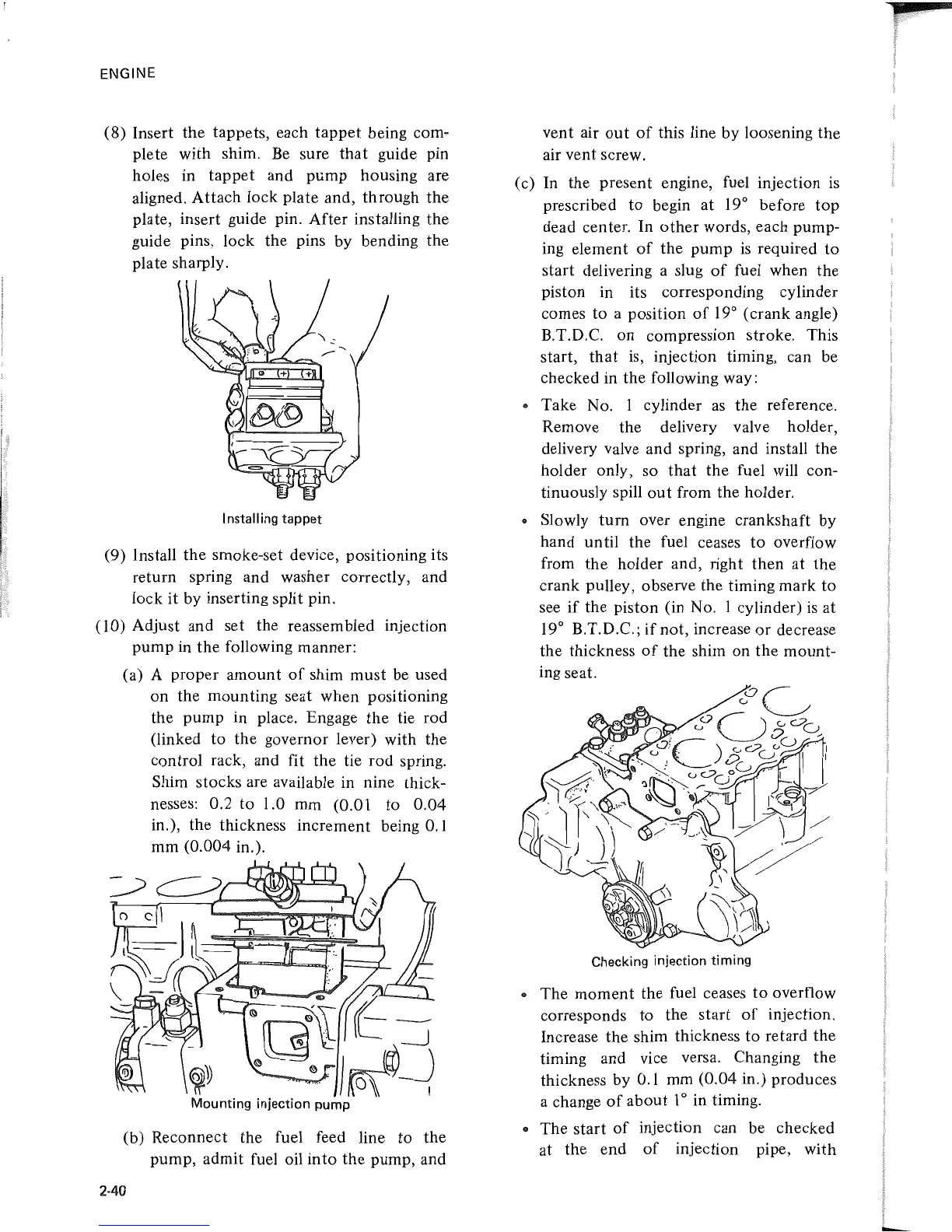

(a) A proper

amount

of

shim

must

be used

on the mounting seat when positioning

the

pump

in place. Engage

the

tie rod

(linked

to

the governor lever) with the

control rack, and fit

the

tie

rod

spring.

Shim stocks are available in nine thick-

nesses: 0.2

to

1.0 mm (0.01

to

0.04

in.), the thickness increment being 0.1

mm (0.004 in.).

(b) Reconnect the fuel feed line

to

the

pump, admit fuel oil

into

the pump, and

2·40

vent air

out

of

this line by loosening the

air vent screw.

(c) In the present engine, fuel injection

is

prescribed

to

begin at 19° before

top

dead center. In

other

words, each pump-

ing element

of

the

pump

is

required

to

start delivering a slug

of

fuel when the

piston in its corresponding cylinder

comes

to

a position

of

19° (crank angle)

B.T.D.C.

on

compression stroke. This

start,

that

is, injection timing, can be

checked in the following way:

..

Take No. 1 cylinder

as

the reference.

Remove the delivery valve holder,

delivery valve and spring, and install the

holder only, so

that

the fuel will con-

tinuously spill

out

from the holder.

..

Slowly

turn

over engine crankshaft by

hand until the fuel ceases

to

overflow

from

the

holder and, right then

at

the

crank pulley, observe the timing mark

to

see

if

the piston (in

No.1

cylinder)

is

at

19°

B.T.D.C.;

if

not,

increase

or

decrease

the thickness

of

the shim on the mount-

ing seat.

Checking injection timing

• The

moment

the fuel ceases

to

overflow

corresponds

to

the start

of

injection.

Increase the shim thickness

to

retard the

timing and vice versa. Changing the

thickness by 0.1 mm (0.04 in.) produces

a change

of

about lOin timing.

..

The

start

of

injection can be checked

at the end

of

injection pipe, with

p

Loading...

Loading...