Replace high pressure

sensor.

Check unit side.

• Isn’t the air circulation

of outdoor unit short-

circuited?

• Are installation spaces

adequate?

• Isn’t there any fouling

or clogging on heater

exchanger?

Control operation check*

Defective outdoor control

PCB

➞

Replace.

Excessive refrigerant

amount: Recharge

refrigerant by weighing

proper amount on a scale.

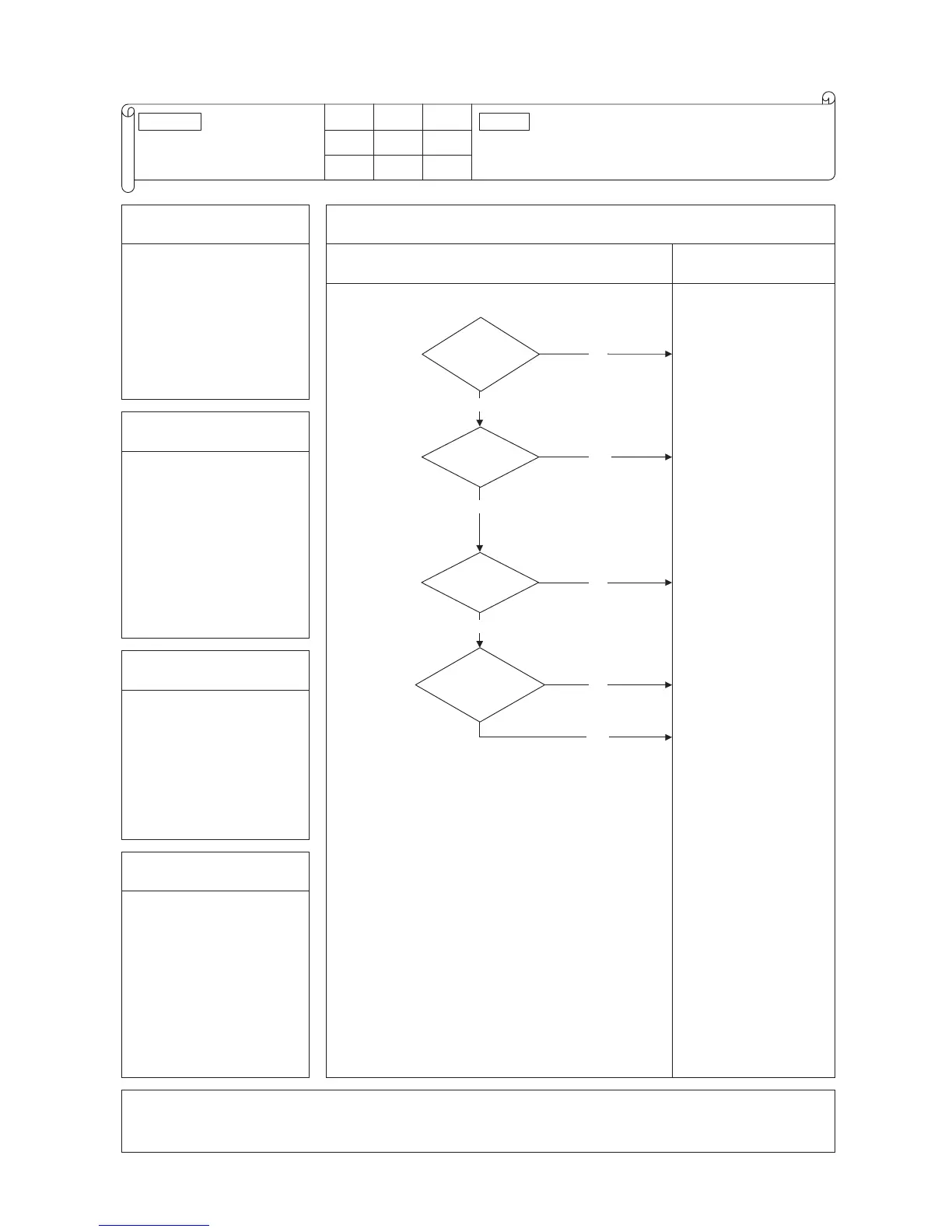

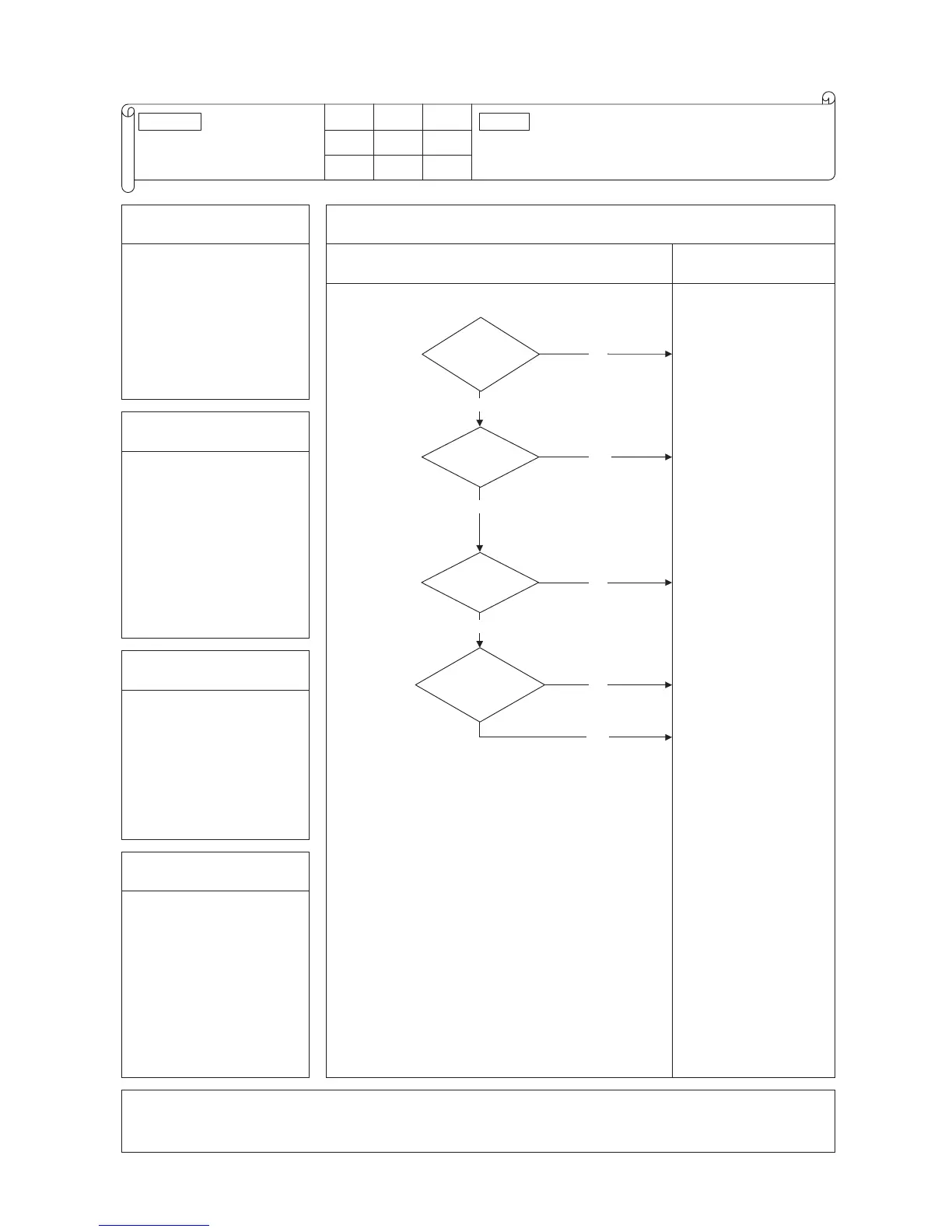

2. Error detection method

For the error detection method,

refer to the protective control by

controlling compressor rotation

speed and cooling high pressure

protective control of micro

computer control function for

corresponding models.

(

Refer to 41 page

)

3.

Condition of Error displayed

• When anomalous rise of

the high pressure sensor is

detected 5 times within 1 hour.

• When high pressure sensor

anomaly is detected for 10

minutes continuously.

4. Presumable cause

• Defective high pressure sensor

•

Defective outdoor control PCB

• Indoor, outdoor unit

installation spaces

• Short-circuit of air on indoor,

outdoor units

• Fouling, clogging of heat

exchanger

• Excessive refrigerant quantity

Note:

Cooling

high pressure

operation

(

Model SCM100

,

125

)

Loading...

Loading...