-

55

-

6. FORMING PIPING AND DRAIN HOSE

1. Forming piping

Piping is possible in the right, rear, downward, left, left rear or left downward direction.

NOTE

the panels when connecting pipes.

Cut out the panel smoothly along the

line in case of side or bottom piping.

Left hand side piping Right hand side piping

Piping in the left direction

Piping in the left rear direction

Piping in the right rear direction

Piping in the right direction

Forming of pipings

• Hold the bottom of the

before stretching it

and shaping it.

Taping of the exterior

• Tape only the portion that

goes through the wall.

• Always tape the wiring

with the piping.

Pipings

2. Drain change procedures

(1) Remove the screw and drain hose.

(2) Remove the drain cap by hand or pliers.

(3) Insert the drain cap which was removed at procedure (2) securely using a hexagonal wrench etc.

(4) Install the drain hose and screw securely.

Screw

Drain cap

CAUTION

Incorrect installation of drain hose and cap can cause water leakage.

7. DRAINAGE WORK

• Arrange the drain hose in a downward angle.

• Avoid the following drain piping.

Wavy

The drain hose

tip is in water.

The gap to the ground

is 5 cm or less.

The drain hose tip

is in the gutter.

Odor from

the gutter

• Pour water to the drain pan located under the heat exchanger, and ensure that the water is discharged outdoor.

• When extended drain hose is present inside the room, insulate it securely with heat insulator available in the market.

Since this air-conditioner is designed to collect dew drops on the rear surface to the

drain pan, do not install the connecting wire above the gutter.

CAUTION

Incorrect drainage work can cause water leakage.

8. INSTALLING INDOOR UNIT

Installing the indoor unit to installation board Removing the indoor unit from installation board

(1) Remove the bottom panel. (Refer to 5.2)

(2) Pull the indoor unit base latch downward. (both right and left

hand sides). (The indoor unit base latch can be removed from the

installation board.)

(3) Push up the indoor unit upward so that it can be removed from

installation board.

Bottom panel

Wall

Installation board

Indoor unit base latch

(2 locations)

(1) Pass the pipe through the hole

in the wall, and hook the upper

part of the indoor unit to the

installation board.

(2)

Gently push the lower part to

fix the indoor unit base lower

latch to installation board.

Installation board

Wall

Installation board

Indoor unit base latch

(2 locations)

Latch (7 locations)

(3) Install the latches of the bottom panel

(7 locations).

Secure the bottom panel with the 3 screws

(in the cap).

9. CONNECTING PIPING WORK

1. Preparation of connecting pipe

1.1. Selecting connecting pipe

Select connecting pipe according to the following table.

Model SRK20/25/35 Model SRK50/60

Gas pipe ø9.52 ø12.7

Liquid pipe ø6.35 ø6.35

• Pipe wall thickness must be greater than or equal to 0.8 mm.

• Pipe material must be O-type (Phosphorus deoxidized seamless copper pipe ICS 23.040.15, ICS

77.150.30).

1.2. Cutting connecting pipe

(1) Cut the connecting pipe to the required length with pipe cutter.

(2)

Hold the pipe downward and remove the burrs. Make sure that no foreign material enters the pipe.

(3) Cover the connecting pipe ends with the tape.

2. Piping work

2.1. Flaring pipe

(1)

(2)

Flare dimensions for R32 are different from those for conventional refrigerant.

-

-

ment gauge.

Copper pipe

outer diameter

A

0

–0.4

B

Copper pipe

outer diameter

Rigid (clutch) type

R32 or R410A Conventional

ø6.35 9.1 ø6.35

0-0.5 1.0-1.5ø9.52 13.2 ø9.52

ø12.7 16.6 ø12.7

2.2 Connecting pipes

(1) Connect pipes on both liquid and gas sides.

Gas side

Service valve size (mm) Tightening torque (N·m)

ø6.35 (1/4") 14-18

ø9.52 (3/8") 34-42

ø12.7 (1/2") 49-61

CAUTION

•

can cause refrigerant leakage.

•

leakage.

3. Heating and condensation prevention

(1) Dress the connecting pipes (both liquid and gas pipes) with insulation to prevent it from heating and

dew condensation.

Use the heat insulating material which can withstand 120°C or higher temperature. Make sure that insu-

lation is wrapped tightly around the pipes and no gap is left between them.

(2) Wrap the refrigerant pipings of indoor unit with indoor unit heat insulation using tape.

(3) -

sulation pad (standard accessory provided with indoor unit).

(4) Wrap the connecting pipes, connecting cable and drain hose with the tape.

(2) (3) (4)

NOTE

Locations where relative humidity exceeds 70%, both liquid and gas pipes need to be dressed with 20mm

or

thicker heat insulation materials.

CAUTION

• Improper insulation can cause condensate(water) formation during cooling operation.

Condensate can leak or drip causing damage to household property.

• Poor heat insulating capacity can cause pipe outer surface to reach high temperature during heating

operation. It can cause cable deterioration and personal injury.

4. Finishing work

Pipe

assembly

(h)Screw

(1) Make sure that the exterior portion of connecting pipes, connecting cable and

drain hose is wrapped properly with tape. Shape the connecting pipes to match

with the contours of the pipe assembly route.

(2) Fix the pipe assembly with the wall using clamps and screws. Pipe assembly

should be anchored every 1.5m or less to isolate the vibration.

(3) Install the service cover securely. Water may enter the unit if service cover is

not installed properly, resulting in unit malfunction and failure.

WARNING

(only for R32)

•

must/shall be installed outdoors.

•

allowed indoors.

CAUTION

Make sure that the connecting pipes do not touch the components within the unit. If pipes touch the

internal components, it may generate abnormal sounds and/or vibrations.

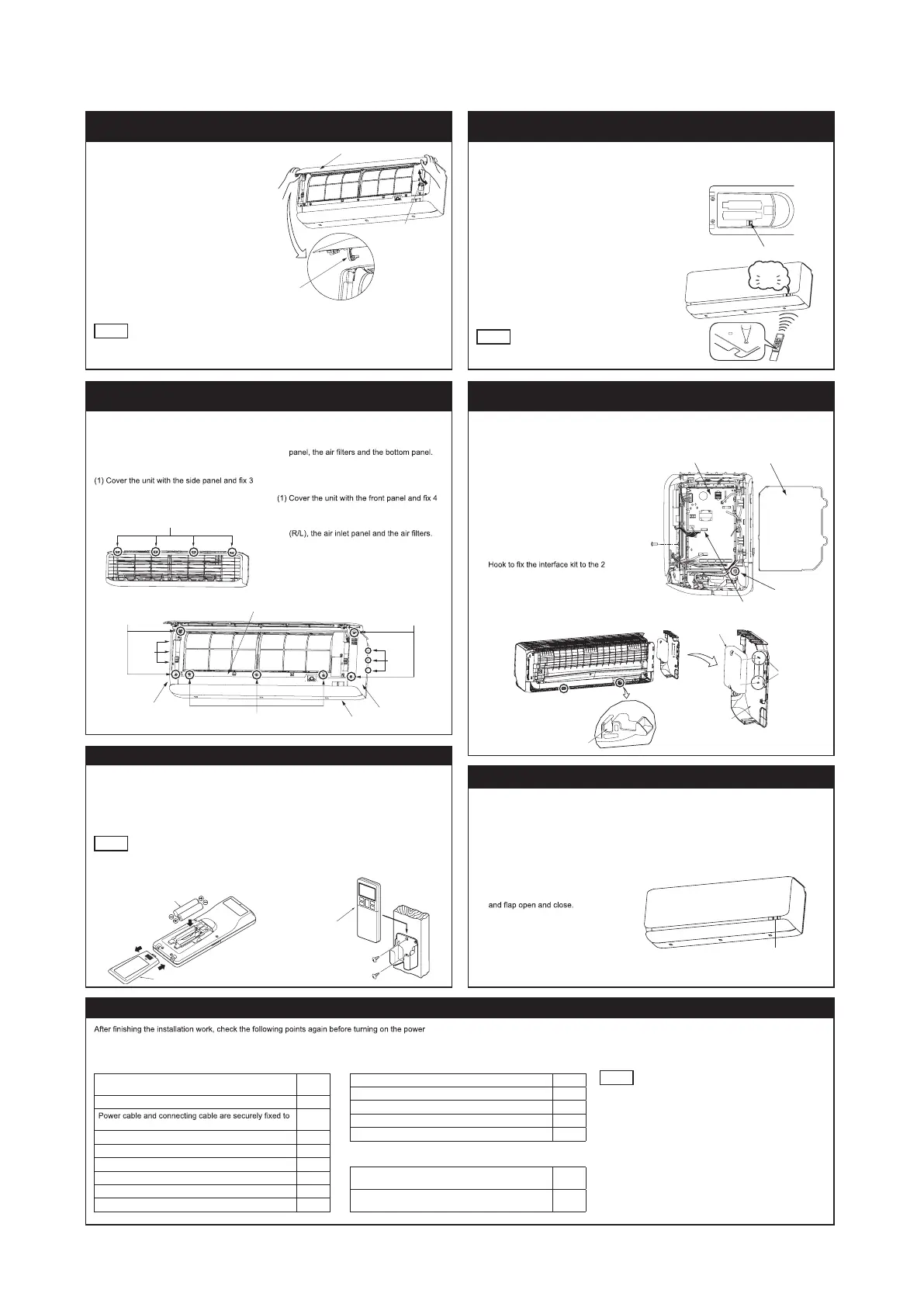

10. HOW TO OPEN, CLOSE, REMOVE AND INSTALL

THE AIR INLET PANEL

13.

INSTALLING TWO AIR-CONDITIONERS IN THE SAME ROOM

1. Open

Pull the air inlet panel at both ends of lower part

and release latches, then pull up the panel until

you feel resistance.

(The panel stops at approx. 60° open position)

2. Close

Hold the panel at both ends of lower part, lower

it downward slowly, then push it slightly until the

latch works.

3. Removing

Open the panel by 80° (as shown in the right

illustration) and then pull it forward.

4. Installing

Insert the panel arm into the slot on the front

panel from the position shown in right illustration,

hold the panel at both ends of lower part, lower

it downward slowly, then push it slightly until the

latch works.

NOTE

• When carrying out maintenance, handle the air

inlet panel with care.

Approx. 80°

m

In case two air-conditioners are installed in the same room, apply this setting so that one unit can be

operated with only one wireless remote control.

Setting one wireless remote control

(1) Slide and take out the cover and batteries.

(2) Cut the switching line next to the battery with

wire cutters.

(3) Set the batteries and cover again.

Setting one indoor unit

(1) Turn off the power source and turn it on after 1

minute.

(2) Send the signal by pressing the ACL switch on

the wireless remote control that was set according

to the procedure described on the above side.

(3) Check that the reception buzzer sound “Peep”

is emitted from the indoor unit. Since the signal

is sent about 6 seconds after the ACL switch is

pressed, point the wireless remote control to the

indoor unit for a while.

NOTE

If no reception buzzer is emitted, restart the setting

from the beginning.

TIME SETUP ACL

Reception

Peep

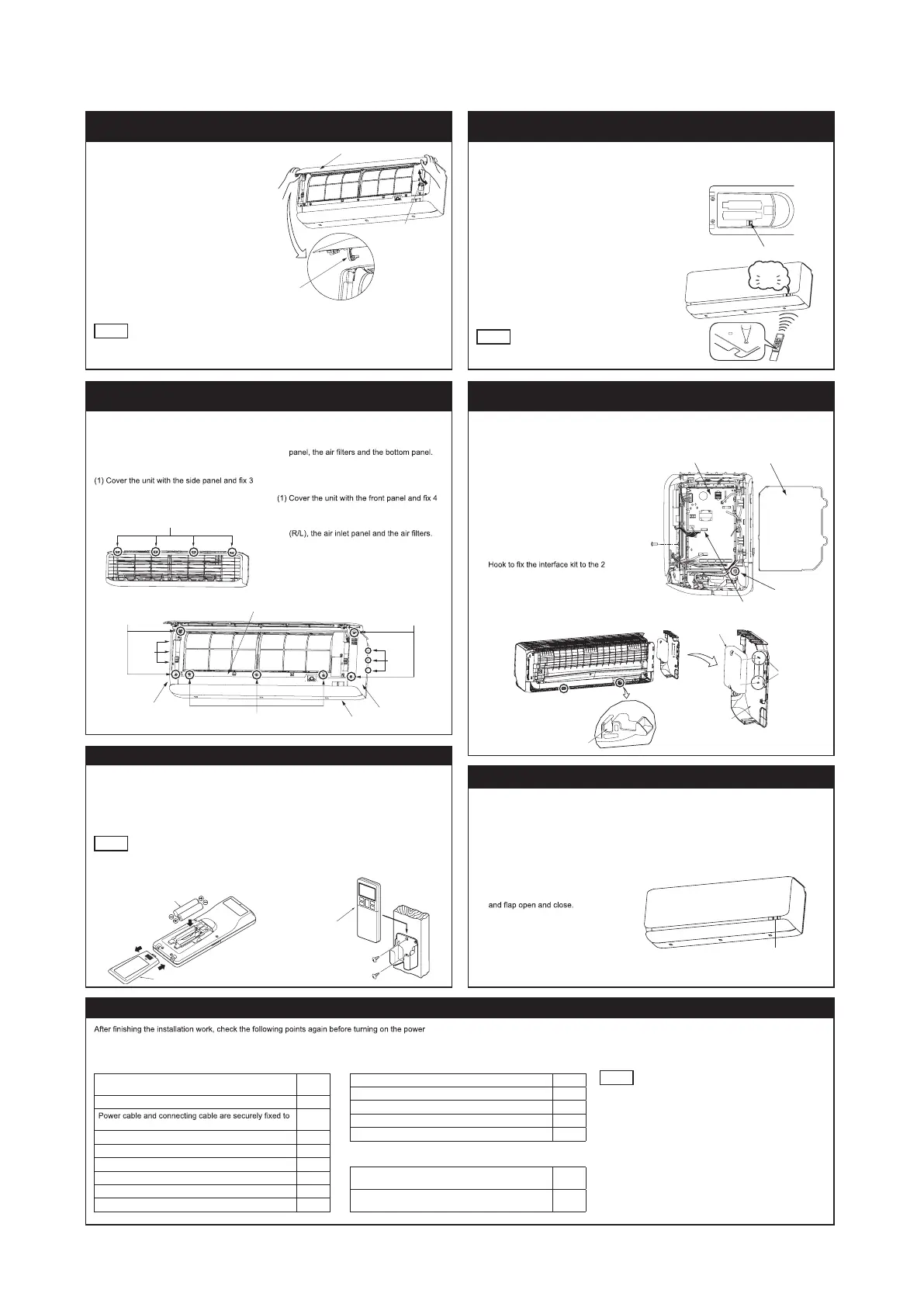

11. HOW TO REMOVE AND INSTALL THE SIDE AND

FRONT PANEL

14. TERMINAL CONNECTION FOR AN INTERFACE

1. Side panel (R/L)

1.1. Removing

(1) Remove the 2 screws.

(2) Remove the 3 latches and then side panel

can be removed.

1.2. Installing

latches.

(2) Secure the side panel with the 2 screws.

Latch

2. Front panel

2.1. Removing

(1) Remove the side panel (R/L), the air inlet

(2) Remove the 3 screws.

(3) Remove the 4 upper latches and then front

panel can be removed.

2.2. Installing

upper latches.

(2) Secure the front panel with the 3 screws.

(3) Install the bottom panel, the side panel

To install wired remote control, superlink etc., interface kit is needed.

(1)

Remove the air inlet panel, bottom panel

and side panel (R).

(2) Remove the control cover. (Remove the

screw.)

(3) There is a terminal (respectively marked

with CNS) for the indoor control board.

While connecting an interface, connect

to the respective terminal securely with

the connection harness supplied with

an option “Interface kit SC-BIKN-E and

SC-BIKN2-E” and fasten

the connection harness onto the indoor

control box with the clamp and screw

supplied with the kit.

(4)

latches on side panel (L).

For more details, refer to the user’s

manual of “Interface kit SC-BIKN-E and

SC-BIKN2-E”.

Indoor unit PCB

Control cover

Fixing point of

the clamp

Screw (Front panel)

Screw

Side panel (R

Latches

Side panel (R)

Side panel (L)

Latches

Side panel (L)

Pass the interface kit

12. INSTALLING WIRELESS REMOTE CONTROL

Mount the batteries

(1) Slide and take out the cover of backside.

(2) Mount the batteries [R03 (AAA, Micro),

×2 pieces] in the body properly.

(Fit he poles with the indication marks + & −)

(3) Set the cover again.

NOTE

• Do not use new and old batteries together.

• In case the unit is not operated for a long time,

take out the batteries

Installing remote control holder

(1) Select the place where the unit can receive

signals.

(2) Fix the holder to pillar or wall with wood

screws.

15. PUMP DOWN WORK

For the environmental protection, be sure to pump down when relocating or disposing of the unit.

Pump down is the method of recovering refrigerant from the indoor unit to the outdoor unit before the

connecting pipes are removed from the unit. When pump down is carried out, forced cooling opera-

tion is needed.

Forced cooling operation

(1) Turn off the power source and turn it on

again after 1 minute. The air inlet panel

(2) After the air inlet panel closes, press the

ON/OFF button continuously for at least 5

seconds. Then operation will start.

For the detail of pump down, refer to the

installation manual of outdoor unit.

Cover

16. INSTALLATION CHECK AND TEST RUN

. Conduct a test run and ensure that the unit operates properly.

At the same time, explain to the customer how to use the unit and how to take care of the unit following the user’s manual.

Before test run

Before test run, check following points.

Power source voltage complies with the rated voltage of

air-conditioner.

Earth leakage breaker and circuit breaker are installed.

the terminal block.

Both liquid and gas service valves are fully open.

No gas leaks from the joints of the service valves.

Indoor and outdoor side pipe joints have been insulated.

Hole on the wall is completely sealed with putty.

Drain hose and cap are installed properly.

Screw of the terminal cover is tightened securely.

Test run

Check following points during test run.

Indoor unit receives signal of wireless remote control.

Air-conditioning operation is normal.

There is no abnormal noise.

Water drains out smoothly.

Display of wireless remote control is normal.

After test run

Explain the operating and maintenance methods to the

user according to the user’s manual.

Keep this installation manual together with user’s

manual.

NOTE

During restart or change in operation mode, the unit will not start

operating for approximately 3 minutes. This is to protect the unit

and it is not malfunction.

Wood screws

ø3.5 X 16

Wireless remote control

Gas pipe

Insulation

Tape

Insulation pad

Position it so that the slit area faces upward.

Wall

Seal hole with putty

Flared joint outside

for indoor unit

Indoor

unit

Wall hole cover

Left

RLF012A202B_cc.indd 2 H29/09/21 20:19

Loading...

Loading...