17

Display Unit

Counts

up

810

00

8

10

20 10 20 10

60

4

321

1

2

3

4

Tool (1)

Tool (2)

Tool (3)

Tool (4)

Touch

signal

probe

Counts up

Datum

plane (0)

Offset value

Work

piece

Machine table

1 2

3

4

5

Workpiece

Touch signal probe

Datum plane

Workpiece

Machine table

X

0

Scale reference point

Start point (x, y)

Evenly divide by n

End point (x, y)

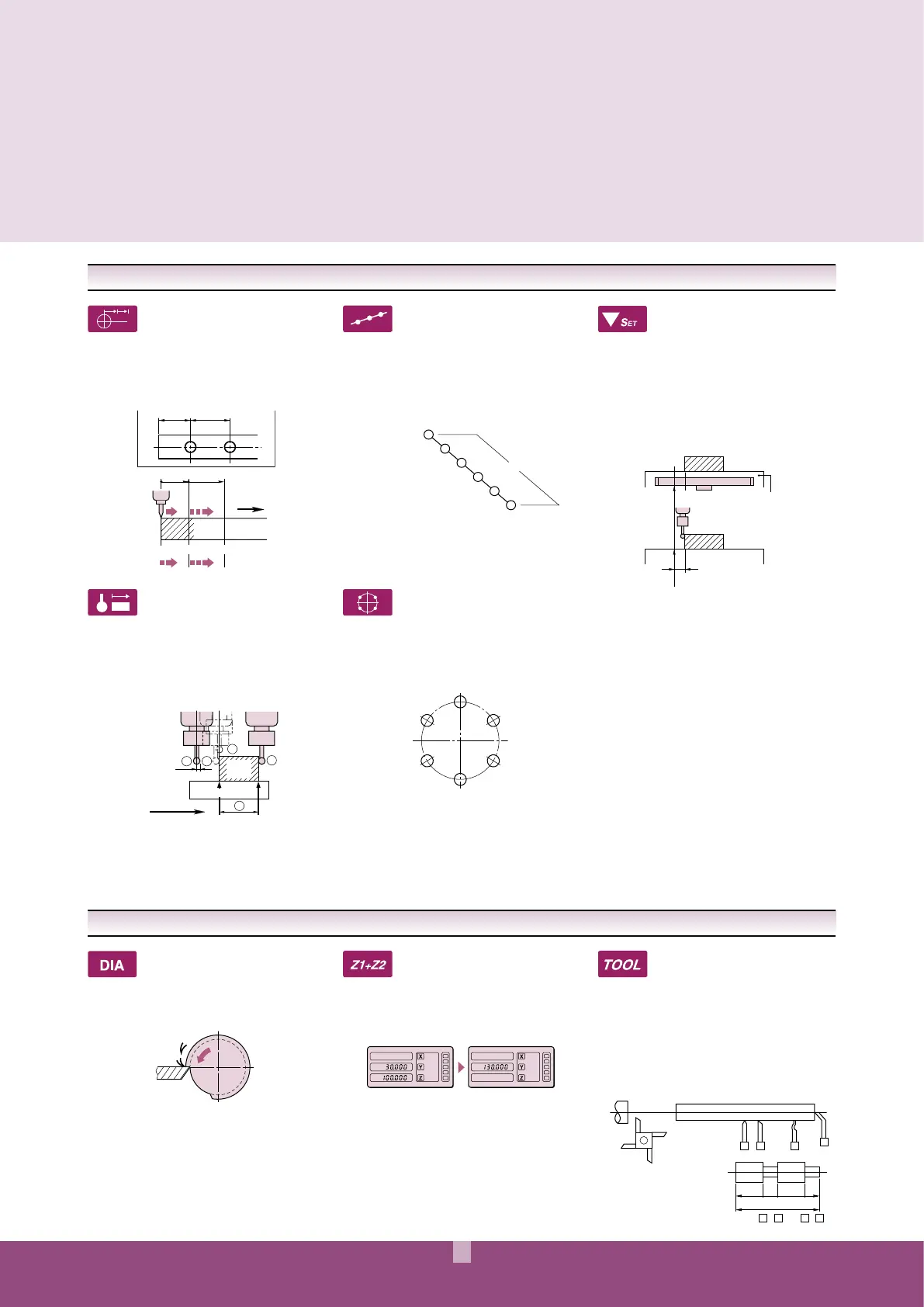

Zero approach machining

[INC mode]

:ERO¬APPROACH¬MACHINING¬CAN¬BE¬REPEATED¬AT¬PRESET¬

intervals. Since the counter keeps the total displacement

in absolute coordinates, a positioning error made by the

operator at one tooling position has no effect on the

remaining positions.

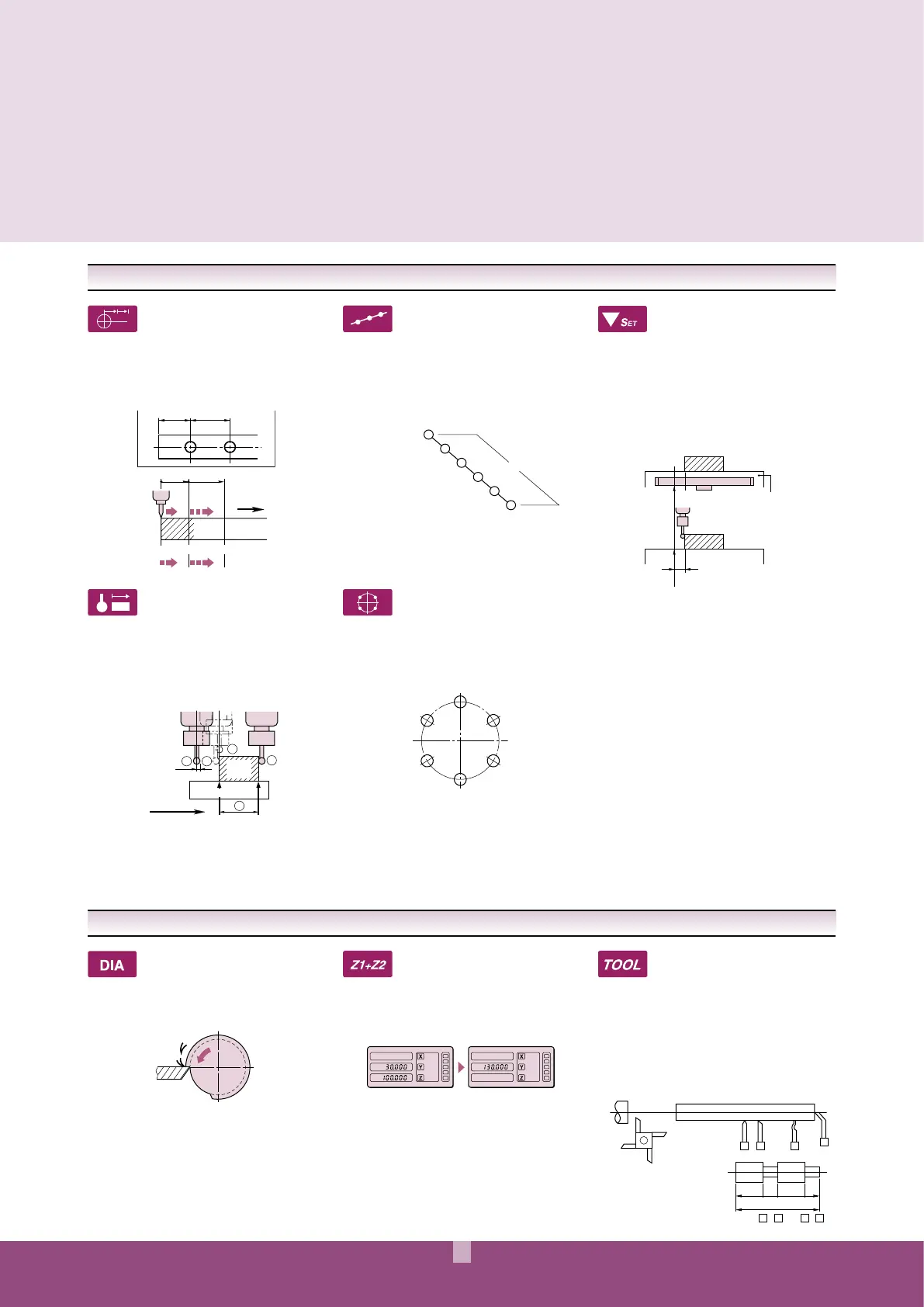

Diameter display

The doubled scale displacement can be displayed. This

convenient function can be used to display the diameter

of a workpiece during a turning operation.

Bolt-hole circle machining

In milling, the drilling positions along the circumference

of the base circle in the absolute zero approach

mode can be easily displayed by entering the center

coordinates, diameter, and number of divisions of the

base circle.

Touch-signal probe

The optional touch-signal probe makes it easy to

perform such operations as datum point setting

(detecting the workpiece edge and setting the counter

display to zero), workpiece centering, and dimensional

measurement (detecting the workpiece end point and

holding the counter display).

Memorization of machining

reference point for each

cutting tool (for KA counter)

Absolute coordinate and incremental coordinate can be

switched by every one of four cutting tools. The counter

can memorize the center of a machining workpiece as

a reference point and it can display the diameter of the

machine workpiece by using absolute coordinate. The

counter can zeroset/preset at the arbitrary position by

using incremental coordinate.

Scale reference point setting

4HE¬LINEAR¬SCALE¬HAS¬SCALE¬REFERENCE¬POINTS¬AT¬MM¬

intervals. When one of the points is detected, the linear

scale issues a signal to hold/restart counting. If the

distance from a scale reference point to the machine

origin is registered as the offset value, it will be retained

even when the power is off (hold function). When the

power is turned on, the machine origin or machining

datum can be easily recalled (set function).

Addition of 2-scale data

The sum of the displayed values of two axes can be

displayed. If a machine has two feed components, fine

feed and coarse feed, each with its own scale, this

function can be used to sum the two feed values.

Pitch machining

"ORES¬HOLES¬BETWEEN¬TWO¬ARBITRARY¬POINTS¬ON¬THE¬89¬

PLANE¬AT¬EQUAL¬SPACES¬"Y¬INPUTTING¬THE¬NUMBER¬OF¬HOLES¬

and positions of the start and end points, holes can

be bored easily at equal spacing. Errors due to table

positioning by the machine are automatically corrected

to the next target value.

LATHE FUNCTIONS

MILLING MACHINE FUNCTIONS

Loading...

Loading...