18

14. Do not exceed the maximum press capacity and/or maximum actuator displacement (if in doubt use

the pressure gauge to determine the applied pressure).

15. On nishing work open the release valve.

16. Avoid situations where the work piece can fall off the press worktable.

17. Only work on one piece at a time.

18. The machine is not designed for long-term loading.

19. Never introduce any modications to the machine.

20. Do not perform mechanical or similar works (welding, cutting, etc.) on the work piece.

21. After completion of work, the machine must be secured against unauthorized use.

22. The machine must be regularly controlled and its damaged or worn and torn parts must be replaced

with new ones

by an authorised service

23. The work piece accidentally slipping or falling off the worktable constitutes a risk of injury or death.

24. When transporting and handling the hydraulic press between the warehouse and the destination, take

into account the occupational health and safety principles for manual transport operations which apply

in the country where the hydraulic will be used.

25. Do not operate if tired or intoxicated.

26. The surface under the press should be dry and level. It should be stable and maintain correct balance

whilst the press is in use. Use protective non-slip boots.

27. Press operators should wear safety goggles and a face mask to protect against possible impact as well

as heavy duty protective gloves. Do not put objects or limbs close to articulated parts.

28. The device is not resistant to the negative effects of the elements.

29. Secure the load to prevent it from moving on the worktable during press operation (the work piece

should be centred).

30. Do not press items with spring like qualities (e.g. springs) or elements which could crack and/or break

under pressure or objects which could explode.

Failure to follow recommended safety instructions may result in injury or death

III. INTENDED USE OF THE MACHINE

The Hydraulic Shop Press is designed for repair and service workshops as well as industrial facilities. It is

useful for mechanics, farmsteads and other workshops etc.The press is designed for pressing (e.g. bearings),

bending and rectifying elements. The press includes an adjustable height worktable (depending on the model)

so that its height can be set at a level ideally suited for the given task.

Any damage resulting from the misuse of the device is to be paid by the user!

Rev. 09.12.2016

19

Rev. 09.12.2016

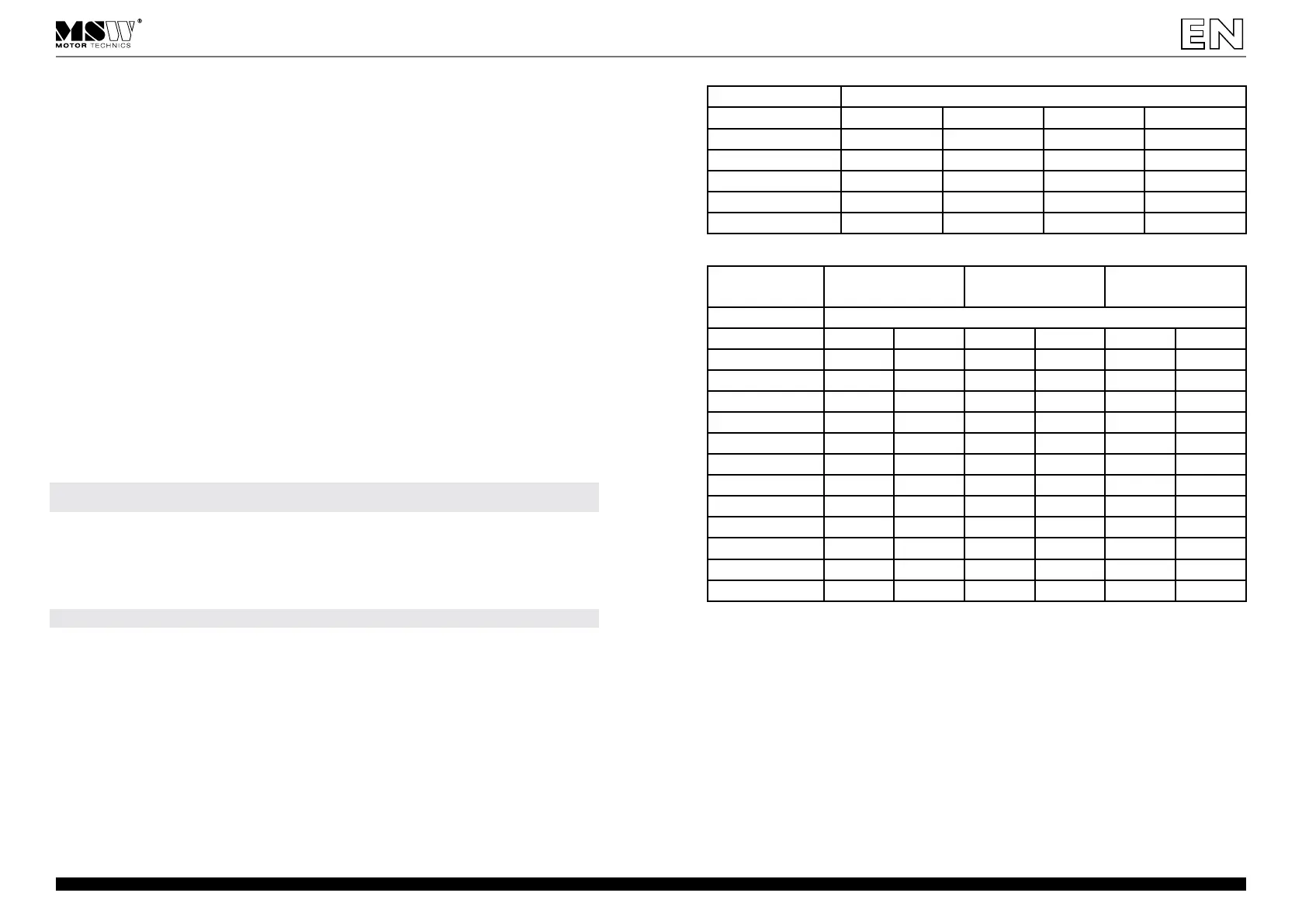

IV. TECHNICAL SPECIFICATIONS

Product name Hydraulic Shop Press

Model MSW-WP-10T MSW-WP-30T MSW-WP-30T-P MSW-WP-50T-P

Art. No. 6300 6301 6302 6303

Pressure 10 T 30 T 30 T 50 T

Piston stroke 130 mm 160 mm 160 mm 180 mm

Width 380 mm 460 mm 460 mm 615 mm

Weight 45 kg 125 kg 145 kg 241 kg

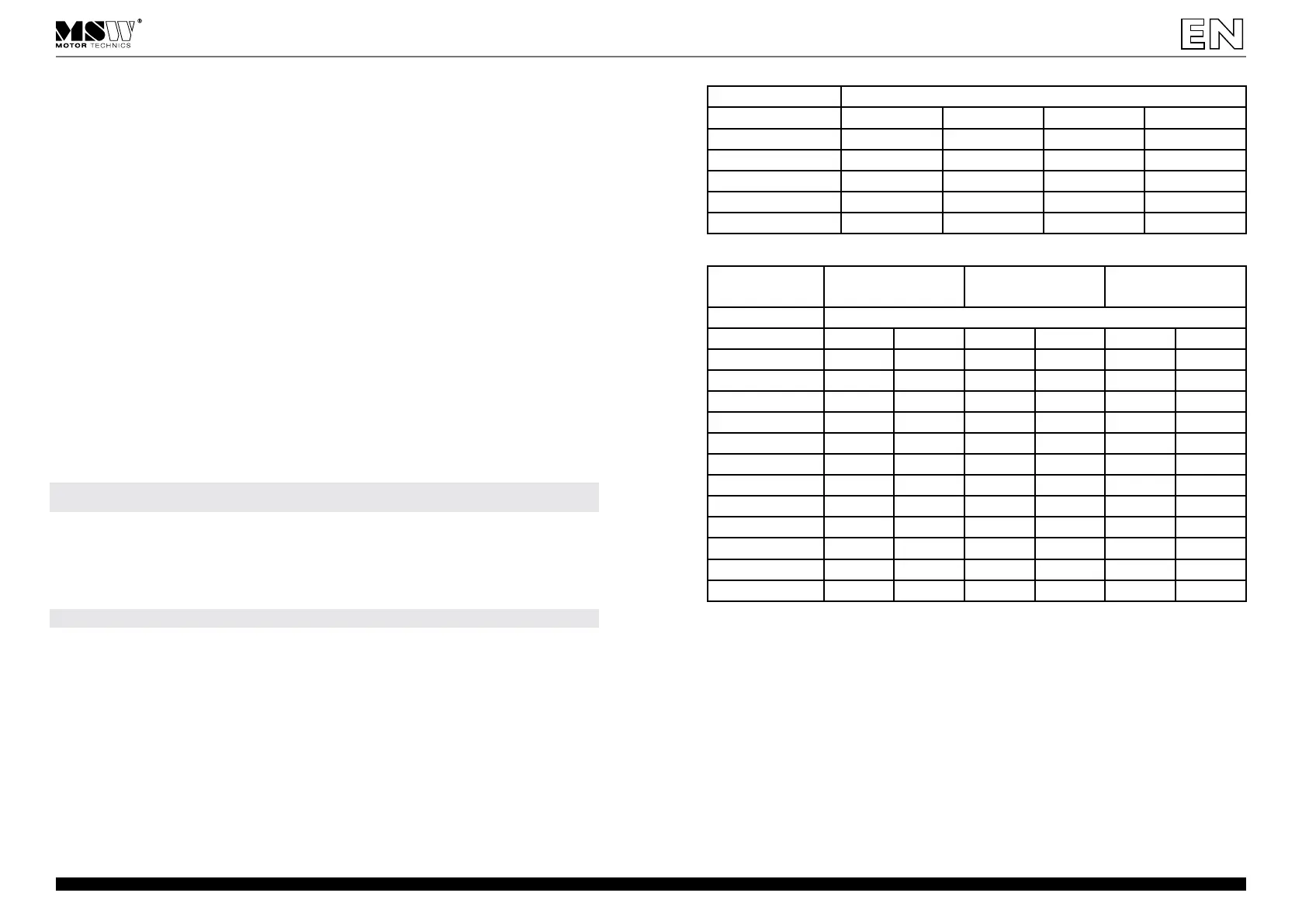

Manometervorgaben:

MSW-WP-10T MSW-WP-30T | MSW-

WP-30T-P

MSW-WP-50T-P

Pressure

Load (T) bar psi bar psi bar psi

2 123 1788 - - - -

4 247 3576 - - - -

6 370 5364 133 1931 - -

8 493 7152 - - - -

10 617 8940 - - 125 1810

12 - - 266 3862 - -

18 - - 400 5793 - -

20 - - - - 250 3621

24 - - 533 7725 - -

30 - - 666 9656 375 5431

40 - - - - 499 7242

50 - - - - 624 9052

V. BEFORE FIRST USE

Upon receipt of the goods, check the packaging for damage and open it. If the packaging is damaged, please

contact your transport company and distributor within 3 days and document the damages as detailed as

possible. Do not turn the package upside down! When transporting the package, please ensure that it is kept

horizontal and stable. The various items used for packaging (cardboard, plastic straps, polyurethane foam)

should be conserved, so that the machine can be sent back to the service center in the best condition in

case of any problems

VI. ASSEMBLING THE MACHINE

Before placing the machine in its working position, inspect it for any damage. Make sure the surface is level

and its load bearing parameters are sufcient for the weight of the machine. Users are responsible for

positioning the machine correctly. Assemble the machine with due care and observe all OHS requirements

to avoid risk of injury. Make sure the work pieces are clean and satisfy the aforementioned requirements, i.e.

not brittle, does not break or spring under loading.

Loading...

Loading...