20

MSW-WP-10T

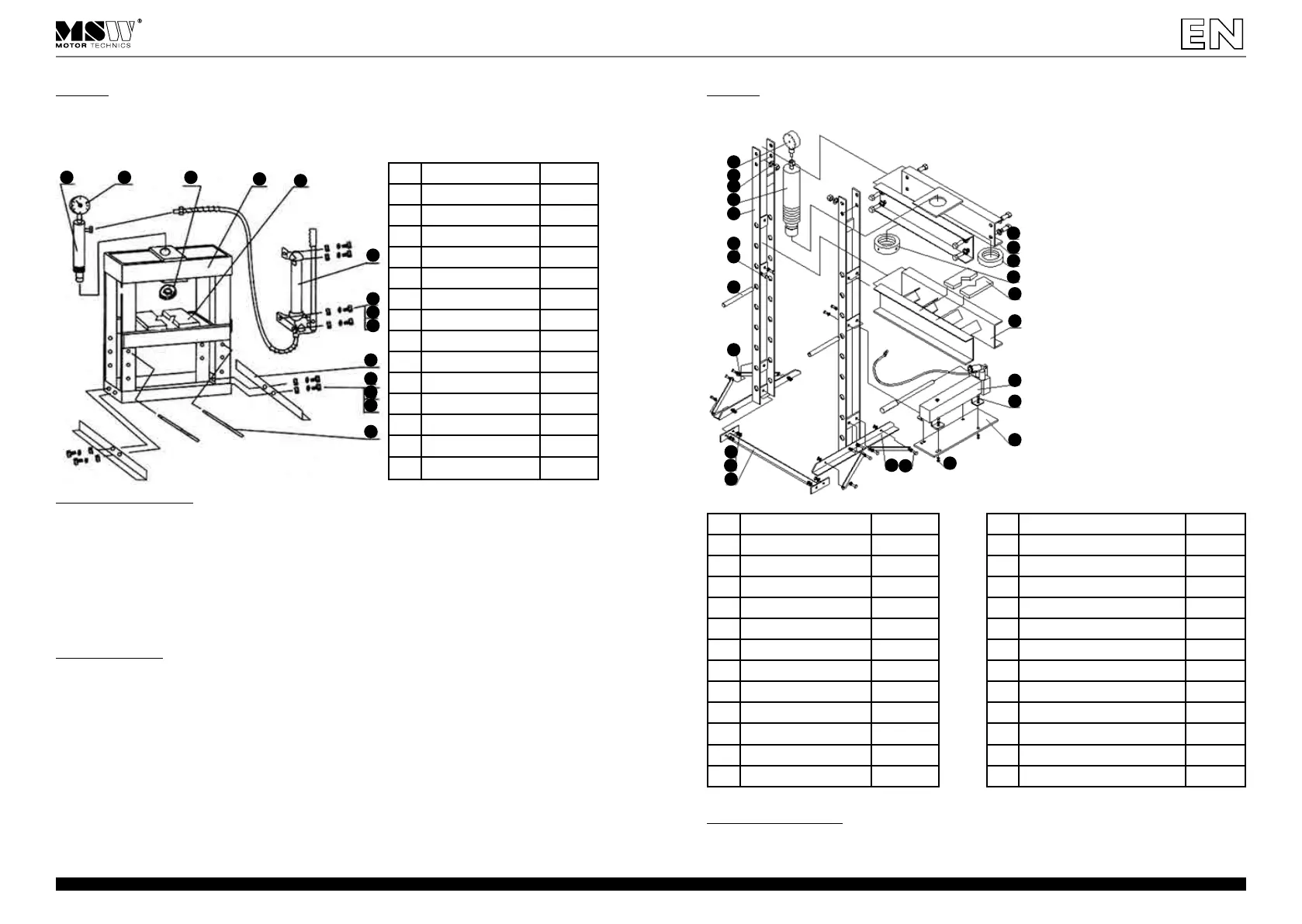

Operation

Hydraulic Shop Press assembly:

Rev. 09.12.2016

1 2 3

4

5

6

7

8

9

10

11

12

13

14

No. Description Quantity

1. Piston 1

2. Manometer 1

3. Attachment 1

4. Upper frame beam 1

5. Worktable surface 2

6. Pump 1

7. M8x25 bolt 4

8. Washer 4

9. M8 nut 4

10. Pin 2

11. Base bracket 2

12. M8x25 bolt 4

13. Washer 4

14. M8 nut 4

Pressing (piston operation):

1. Set worktable to the required height and secure it using two pins.

2. Position work piece on the worktable.

3. Close the release valve near the manual pump lever by twisting it clockwise.

4. Pump using the lever until the piston is near the work piece.

5. Align the axis of the work piece and the piston to ensure symmetric pressure.

6. With the piston by the work piece, monitor manometer readings to avoid overloading the press.

(Maximum press capacity: 617bar / 8940psi -10TONNES).

7. Apply pressure to the work piece by further pumping until desired result is achieved.

Retracting the piston:

1. Stop using the lever and slowly open the release valve by twisting it anticlockwise. Secure the work

piece to prevent it from falling off the table during pressure release.

2. Only remove the work piece when the piston is completely retracted.

21

Rev. 09.12.2016

MSW-WP-30T

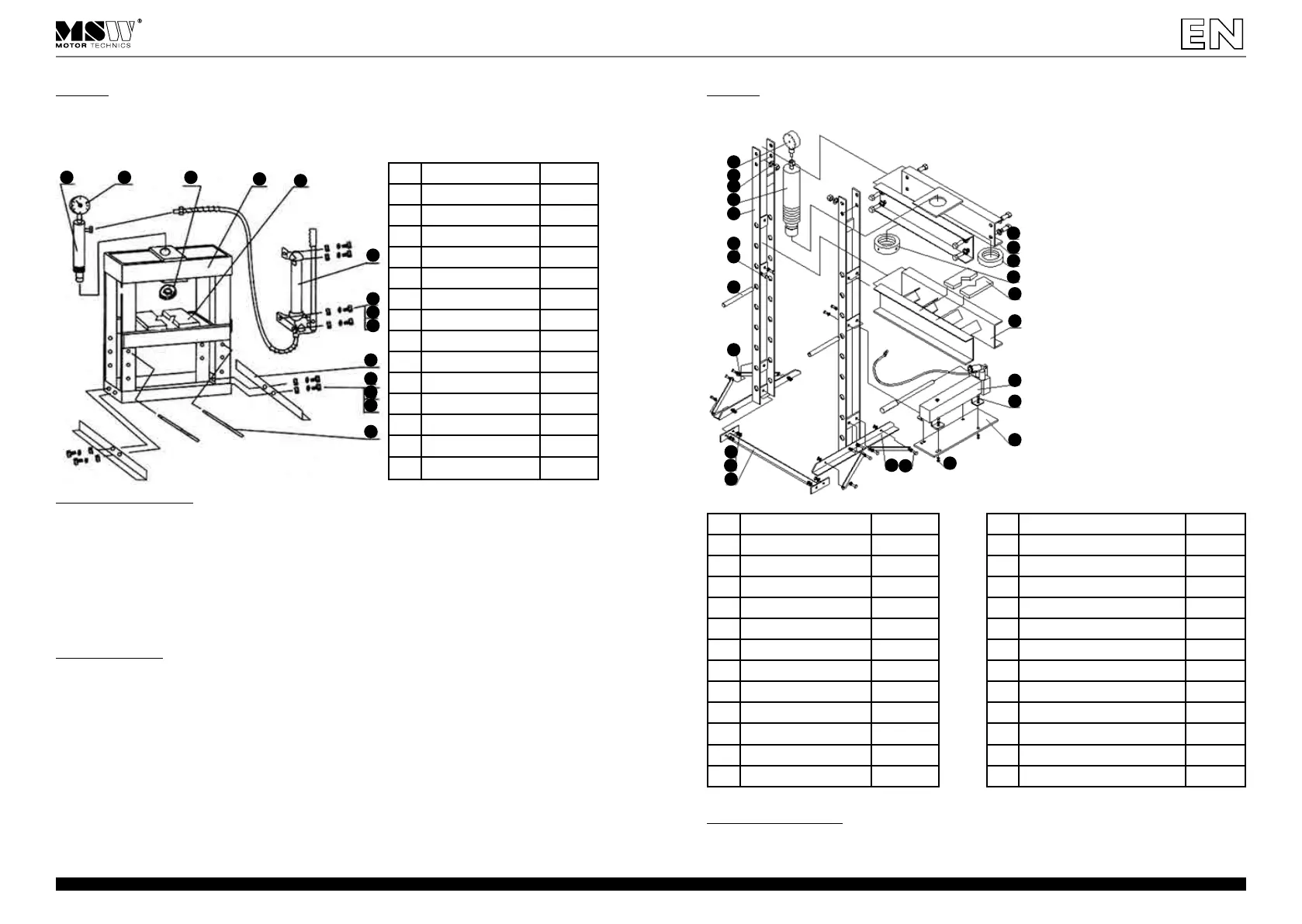

Operation

Hydraulic Shop Press assembly:

No. Description Quantity

1. Manometer 1

2. M20 washer 16

3. M20 nut 8

4. Piston 1

5. Support post 2

6. Washer 2

7. M10x25 bolt 2

8. Pin 2

9. Bracket 4

10. M10 nut 14

11. M10 washer 34

12. Bracket 1

No. Description Quantity

13. M10x25 bolt 12

14. Base bracket 2

15. Plate 1

16. Pump 1

17. Adjustable worktable support 1

18. Worktable surface 2

19. Upper piston coupling 1

20. Lower piston coupling 1

21. Crossbeam 1

22. M20x35 bolt 8

23. M10x25 bolt 4

24. M10 nut 4

1

2

3

4

5

6

7

8

9

10

11

12

14

13

25

15

23

16

17

18

19

20

21

22

Pressing (piston operation)

1. Set worktable to the required height and secure it using two pins.

2. Position work piece on the worktable.

Loading...

Loading...