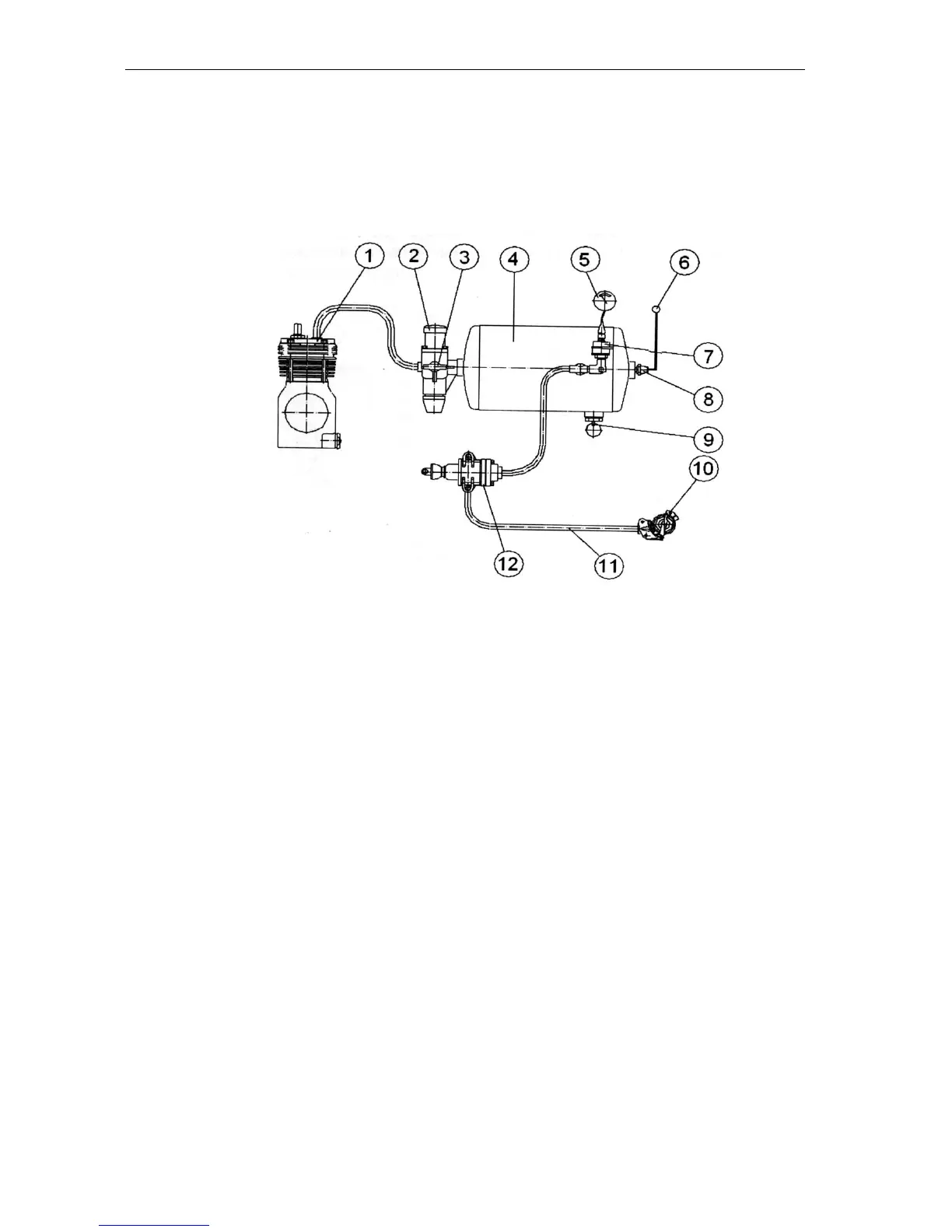

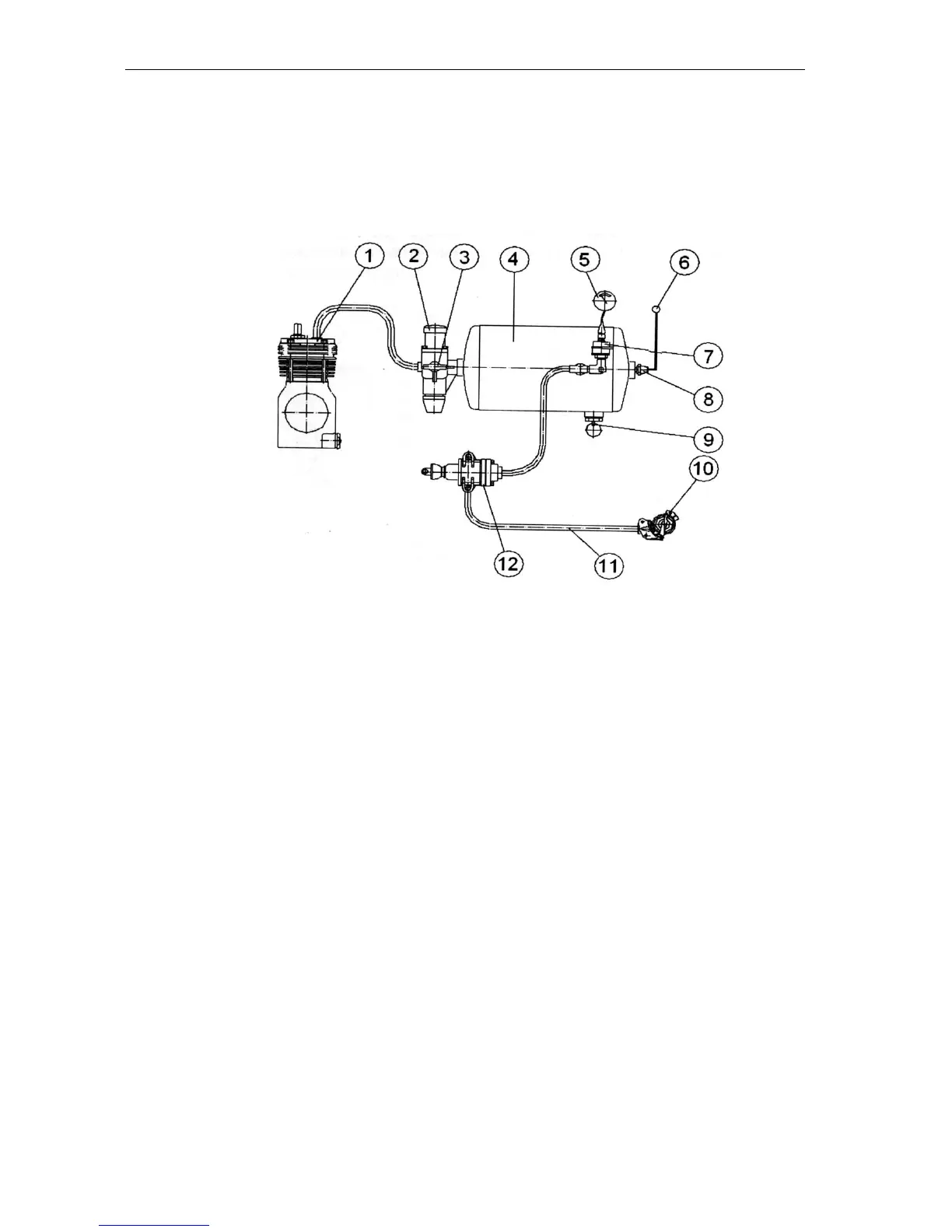

Pneumatic system of trailer brake control

Single-line pneumatic actuator

1 – compressor; 2 – pressure regulator; 3 – air intake valve; 4 – tank; 5 – pressure indi-

cator; 6 – emergency pressure pilot lamp; 7 – pressure transducer; 8 – emergency

pressure sensor; 9 – condensate removal valve; 10 – connecting head; 11 – control

line; 12 – brake valve.

The tractor is equipped with the pneu-

matic system controlling the brakes of

the trailers and other agricultural ma-

chines equipped with pneumatic brake

actuator.

The pneumatic system is also used for

inflating the tyres and other purposes,

when compressed air power is required.

The pneumatic system is also used for

inflating the tyres and other purposes,

when compressed air power is required.

Air is taken to the system from the en-

gine intake manifold. Air is compressed

in the compressor (1) and supplied to

tank (4) via pressure regulator (2) main-

taining the required pressure in the tank.

Compressed air is supplied from the

tank via pipeline to the brake valve (12).

From the brake valve air is passed via

control line (11) to the connecting head

(10) and then to the pneumatic system

of the trailer. The air intake valve (3),

which used for inflating the tyres and

other purposes, is installed in the pres-

sure regulator. To monitor air pressure

in the system, there is a pressure trans-

ducer (7) and the emergency pressure

drop sensor (8) and on the dashboard –

pressure indicator (5) and red pilot lamp

(6). To remove condensate from the

tank, the valve (9) is provided.

The brakes of the trailers and agricultur-

al machines are controlled in two

modes: direct and automatic.

The direct control of the brakes is exer-

cised at the cost of the pressure drop in

the connecting line when braking the

tractor to zero.

The automatic brake control is exercised

by at the cost of the pressure drop to ze-

ro in the trailer connecting line in case of

its disconnection (detachment) from the

tractor. Here the valve in the connecting

head of the tractor is automatically shut

Loading...

Loading...