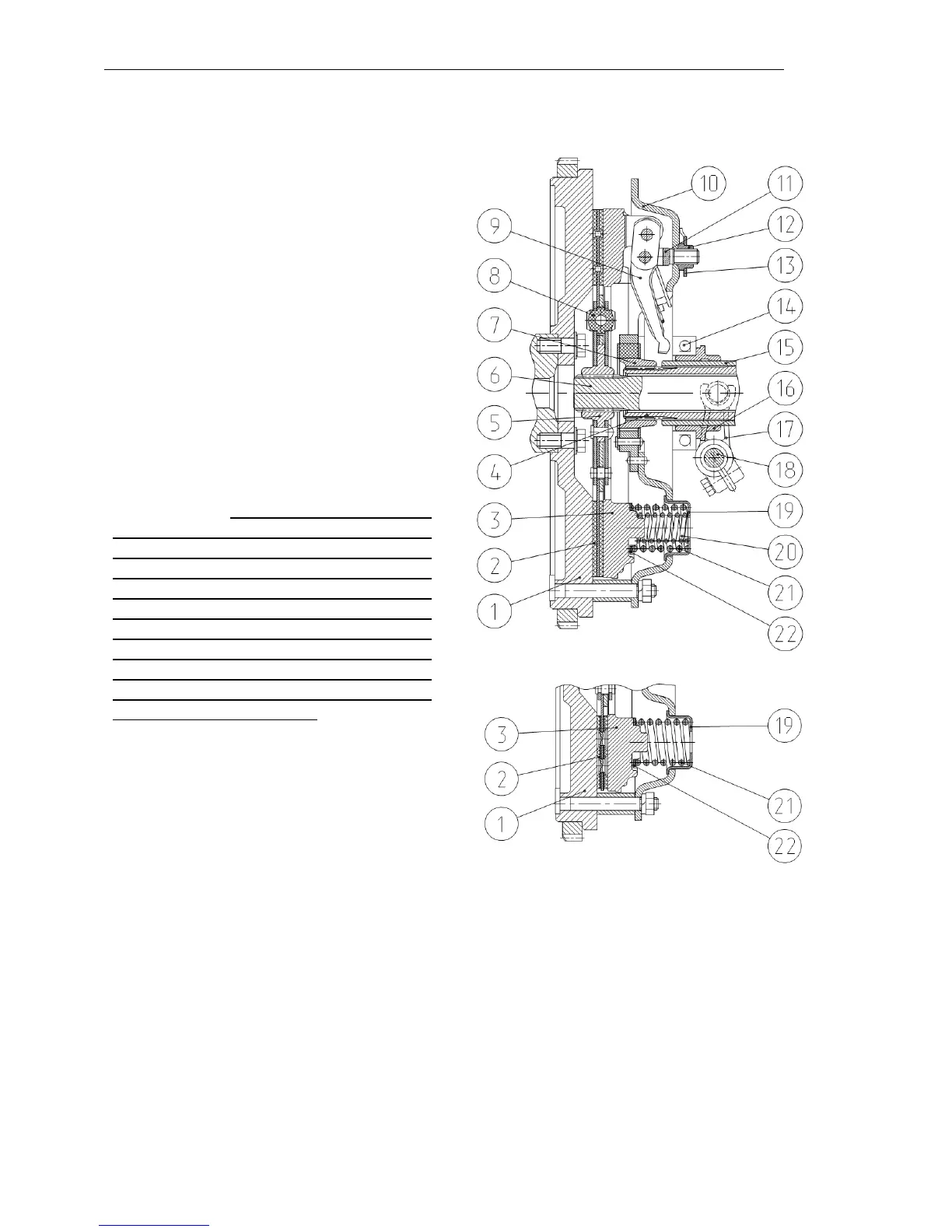

1. General

A dry single-plate spring-loaded clutch is

mounted on the engine flywheel (1) (see

Fig. а).

The driving part of the clutch consists of

the flywheel (1) and pressure plate (3).

The driven part of the clutch includes the

driven plate (2) with the torsional vibra-

tion damper (8) mounted on the power

shaft (6). The necessary force for press-

ing the friction surfaces of the driving

and driven parts is provided by the nine

main springs (21) and six additional

springs (20), if the clutch is equipped

with a driven plate 2 with ceramic-metal

segments (Fig. b), no additional springs

(20) are mounted in this case.

ATTENTION: To avoid the premature

failure of the driven plate and parts of

the transmission, follow the guidelines of

this Manual: in case of installation of a

driven plate with asbestos-free linings

(Fig.а), the clutch plates are fitted with

nine main springs 21 and six additional

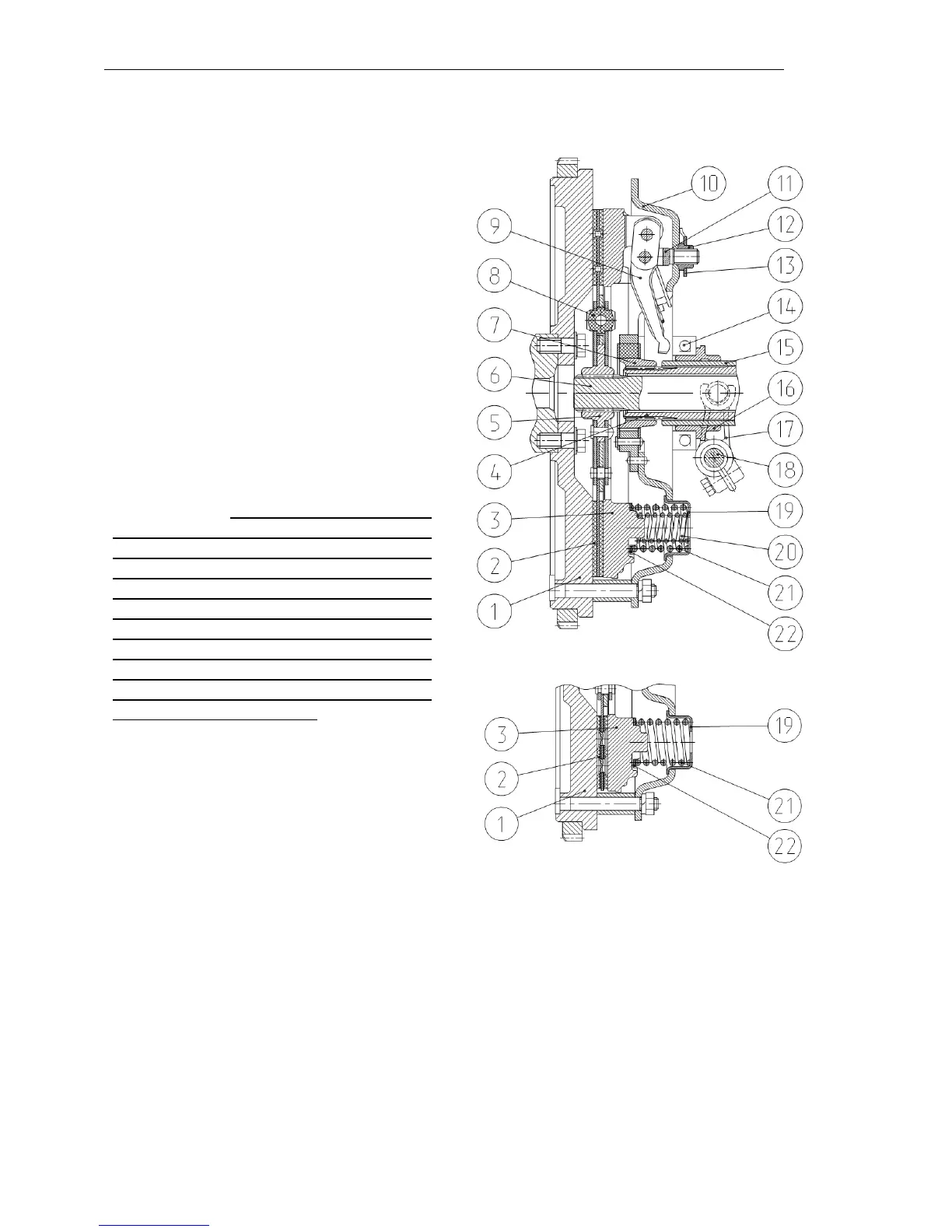

springs 20; in case of installation of a

driven plate with ceramic-metal seg-

ments, the clutch plates are fitted with

nine main springs 21 only.

The elastic components are placed be-

tween the floating bushing (7) connected

with the PTO drive shaft (4) and the

backing plate (10).

The clutch is engaged and disengaged

by means of the shifter (16) with the re-

lease bearing (14) moving over the

bracket (15). The shifter fork (17) with

the roller (18) is connected with the

clutch pedal by means of a rod.

The release bearing (14) is lubricated

through a pressure lubricator screwed in-

to the shifter journal.

a)

b)

1 – flywheel; 2 – driven plate; 3 – pres-

sure plate; 4 – PTO drive shaft; 5 – hub; 6

– power shaft; 7 – floating bushing; 8 –

torsional vibration damper; 9 – clutch lev-

er; 10 – backing plate; 11 – fork; 12 – nut;

13 – locking spring; 14 – bearing; 15 –

shifter bracket; 16 – shifter; 17 – disen-

gagement fork; 18 – control roller;

19 – sleeve; 20 – pressure spring;

21 – pressure spring; 22 – insulating

w a sher.

Clutch

Loading...

Loading...