L-95006N page 2 of 2

NOTE: Read all instructions before beginning installation.

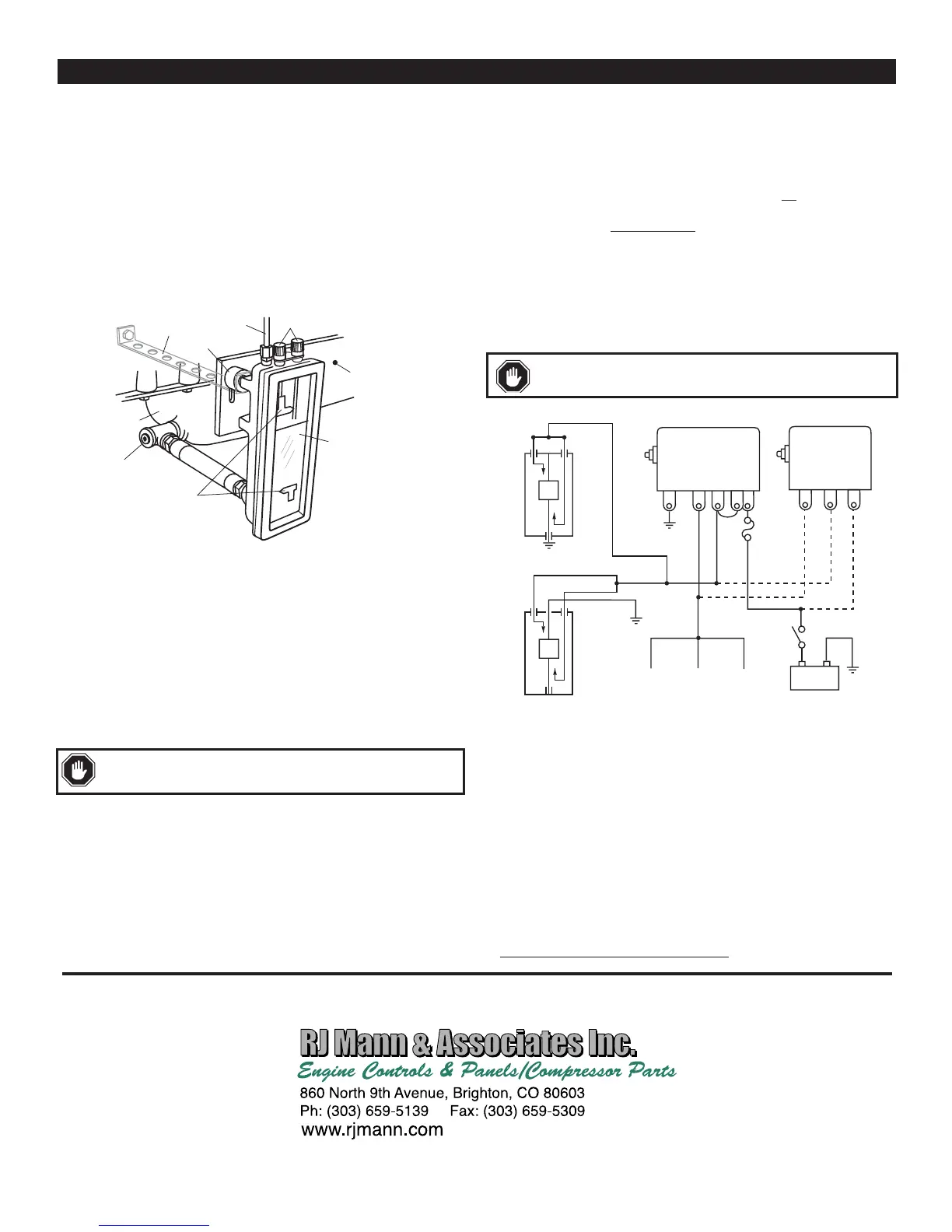

Mounting

1.

Determine which side of the engine to mount the L129. This will normally be the

side of the engine from which it is started. Weld a slotted mounting plate to the

engine skid or attach the mounting plate to the crankcase. If a mounting plate is

not used, a support strap is recommended (see Typical Installation below).

2.

Install the shockmounts in the threaded holes provided in the mounting bosses on

the rear of the L129. NOTE: We recommend using the shockmounts provided

to minimize “contact bounce” resulting in improper operation.

3.

Attach the L129 to the mounting plate as shown below but do not tighten TOO

TIGHT since you will have to adjust the L129 later in the installation process.

Connecting Hoses and Fittings

1.

DRAIN THE CRANKCASE. If the crankcase does not have an auxiliary plug or

connection, connect the L129 to the crankcase drain plug connection. This con-

nection will n

ormally be a straight (parallel) thread which seals with a copper or

fiber washer. NOTE: If the drain plug on the crankcase is used for the connection,

we recommend installation of a tee to allow draining of the crankcase for service.

2.

Flexible hose or rigid pipe can be used to attach the L129 to the engine

crankcase. Flexible hose is to be 1/2 in. (13 mm) I.D. minimum and made of

quality material. Use of flexible hose will allow you to adjust the height of the

L129 to properly reflect the oil level in the crankcase. Also, a swivel connection

on one end of the hose will assist in properly aligning the L129.

Rigid pipe is to be 1/2 inch pipe. If the length of the pipe is relatively short, no

additional support for the L129

may be needed, although it is recommended. A

pipe union is provided in the installation kit.

Attach the hose or pipe from the L129 process connection (1/2 NPT) to the

crankcase.

3.

For vented crankcases, install the tube fitting and copper cane provided in the

installation kit into the top of the L129. Venting to atmosphere will allow the oil

level to rise in the L129 to the same level as in the crankcase, (the pressure/vacu-

um in the L129 and the crankcase must be equal). If the crankcase develops a

positive (pressure) or negative (vacuum) pressure, you MUST connect the

L129 vent back to the crankcase. If you do not do this, the L129 will indicate

high level with a pressurized crankcase and a low level with a vacuum crankcase.

In extreme cases a pressurized system will blow oil out the vent tube or in vacu-

um crankcases can suck oil out of the L129.

To vent the L129 back to the crankcase, install a 1/4 inch (6 mm) O.D.

or larg-

er tubing (copper or flexible) from the L129 vent fitting to a point in the

crankcase above the full oil level or in the fill pipe that is not

restricted by baf-

fles, filters or other obstructions. If connecting directly into the crankcase, be

sure the entry point is clear of oil splash

that can plug the tube opening.

4.

Refill the crankcase to proper oil level. With the engine running and warm, loosen

the L129 from the mounting bracket and adjust the L129 so that the oil level shows

approximately midway or above in the sight glass. Tighten shockmount nuts.

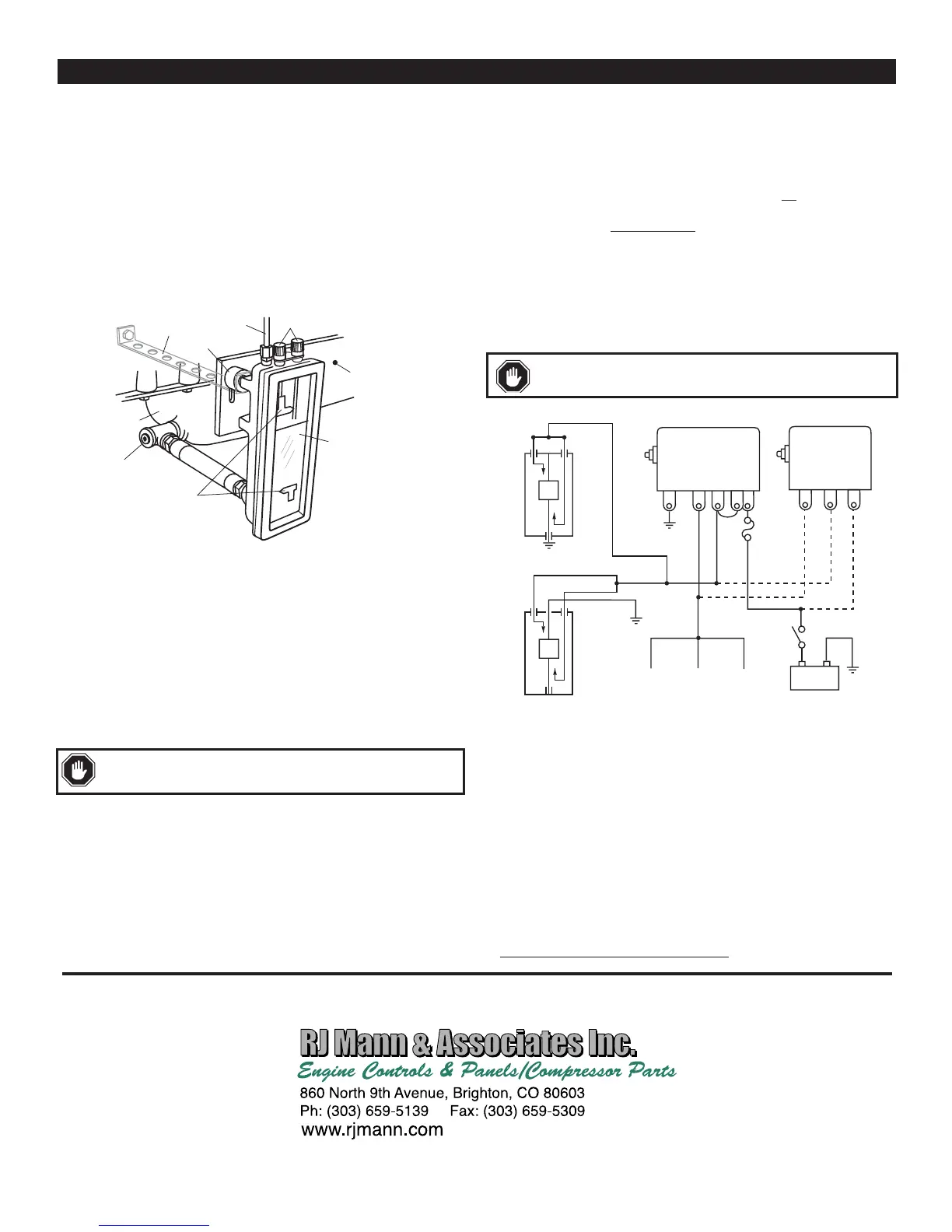

Wiring

Follow appropriate wiring for the alarm or engine shutdown system you are using.

Diagrams below are shown with the float in the “full” position.

Operation Test

The following test is to be performed after the L129 has been installed and the

crankcase has been filled to the proper oil level.

1.

With equipment running, turn the high and low adjust knobs one at a time until

they “make” contact with the float. When contact is made the alarm or shutdown

circuit should actuate.

2.

Return high and low adjustment knobs to the proper contact position before

operating equipment.

Warranty

A limited warranty on materials and workmanship is given with this FW

Murphy product. A copy of the warranty may be viewed or printed by going

to www.fwmurphy.com/support/warranty.htm

INSTALLATION and OPERATION

518PH

C S

117PH

B

G NC

SW1 SW2

B

BLACK

RED

WHITE

HI

HI LOW

LOW

COM.

L129

Magnetic Switches

L129CK1

_

+

Ignition

Coil

Rack Pull

Solenoid

Fuel

Valve

Battery

CAUTION:

WARNING: If both flexible hose and shockmounts are used, a

gr ound wir e must be added between the L129 and the engine.

Customer Supplied

Support Strap

Mounting

Plate

Shockmount

Vent

Contact Adjustment Knobs

High and Low

Contacts

Tee

Crankcase

Sight

Glass

Typical Installation

Contact Rating: 2 A @ 30 VAC/DC, pilot duty.

perform all wiring connections with the battery

disconnected. Observe all contact ratings and voltages.

Loading...

Loading...