Do you have a question about the Murphy VS2 and is the answer not in the manual?

Critical safety instructions before beginning installation of the Murphy product.

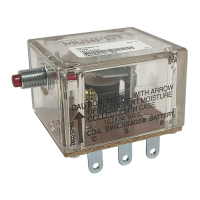

Overview of shock and vibration switches and their applications.

Lists and briefly describes different shock and vibration switch models.

Details the optional electric solenoid for remote reset functionality.

Explains the field-adjustable time delay for VS94 models.

Describes the optional space heater to prevent moisture condensation.

Information regarding the limited warranty for Murphy products.

Detailed physical dimensions and mounting information for the VS2 model.

Detailed physical dimensions and mounting information for the VS2C model.

Detailed physical dimensions for VS2EX and VS2EXR models.

Detailed physical dimensions and mounting information for the VS2EXRB model.

Detailed physical dimensions and mounting information for the VS94 model.

Technical specifications for VS2 and VS2C models, including case and contacts.

Technical specifications for the VS2EX model, including explosion-proof rating.

Technical specifications for the VS2EXR model, including remote reset option.

Technical specifications for VS2EXRB, including Class I, Division 1, Group B rating.

Technical specifications for VS94, including NEMA 4X, optional features.

Crucial safety instruction to disconnect power and stop the machine before installation.

Procedure for installing the VS2C model using the supplied C-clamp.

Steps for firmly attaching the unit to equipment and making electrical connections.

Detailed steps to adjust the sensitivity to prevent false trips.

Instructions for adjusting the time delay feature on VS94 models.

Illustrations showing optimal mounting for balance-opposed and reciprocating compressors.

Illustration showing optimal mounting for a pumping unit.

Illustrations for engine and vertical shaft pump mounting locations.

Illustration showing optimal mounting for generator sets.

Illustration showing optimal mounting for cooling tower fans or heat exchangers.

Illustration showing optimal mounting for an engine compressor.

Illustration showing optimal mounting for a turbine centrifugal compressor.

Diagram of SPDT switch terminals and sensitivity adjustment for VS2/VS2C.

Diagram of SPDT switch terminals and sensitivity adjustment for VS2EX.

Diagram of SPDT switch, remote reset, and sensitivity adjustment for VS2EXR.

Diagram of switches, remote reset, and sensitivity adjustment for VS2EXB/VS2EXRB.

Diagram of switches, optional features, and sensitivity adjustment for VS94.

Wiring diagrams for single or dual CD ignition systems for various models.

Typical wiring diagram for connecting the switches to electric motors.

Wiring diagrams for distributor ignition or diesel engine systems.

List of replacement part numbers for the VS2 model.

List of replacement part numbers for the VS2C model.

List of replacement part numbers for the VS2EX model.

List of replacement part numbers for the VS2EXR model.

List of replacement part numbers for the VS2EXRB model.

List of replacement part numbers for the VS94 Series models.

Loading...

Loading...