LS-04006N page 3 of 4

REPLACING AND INSTALLING THE DVO ASSEMBLY

Tools Needed: Strap or pipe wrench, 9/16" Hex wrench, tubing

cutters and benders and the appropriate tools for the fittings.

1. Block off and bleed the instrument gas pressure supply to the

LS200NDVO/DVOR.

2. Remove the tubing between the LS200NDVO/DVOR and the

scrubber dump valve, and remove the supply gas tubing

(regulator [-R-] if used).

3. Remove the LS200NDVO/DVOR from the vessel (optional).

4. If the LS200NDVO/DVOR was removed from the vessel,

mount it in a suitable vise on a work bench (if possible).

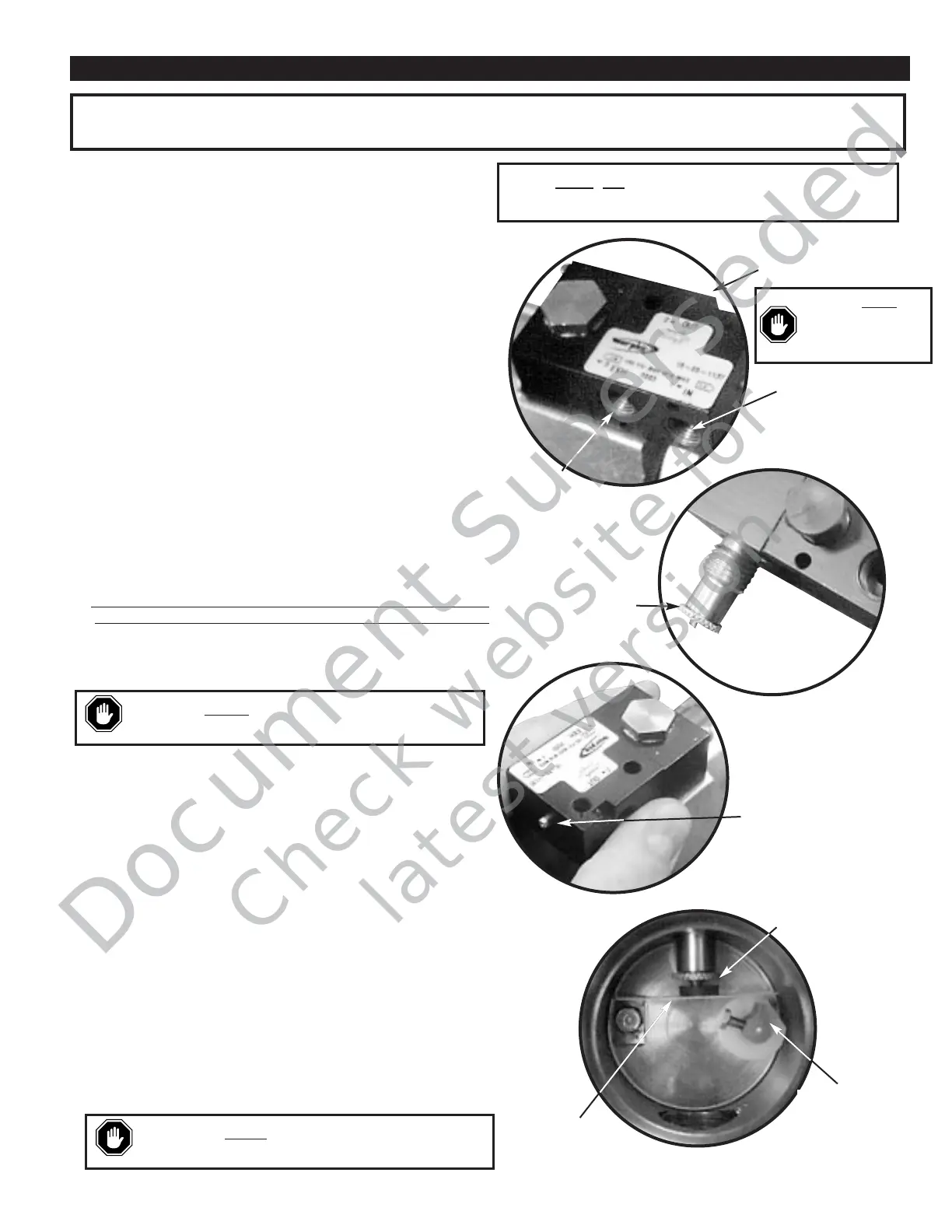

5. Using the proper tools, disconnect the Inlet, Outlet, and Exhaust

fittings from the existing DVO (see fig. 1). You will re-connect

these to the new DVO in a later step.

NOTE: The following steps must be done with the DVO in the

upright position (on top of the LS200NDVO).

6. Remove the LS200NDVO/DVOR cover. The use of a strap

wrench or a pipe wrench may be needed.

7. With a 9/16" hex wrench loosen the hexhead bolt on top of the

DVO and remove the existing DVO from the body.

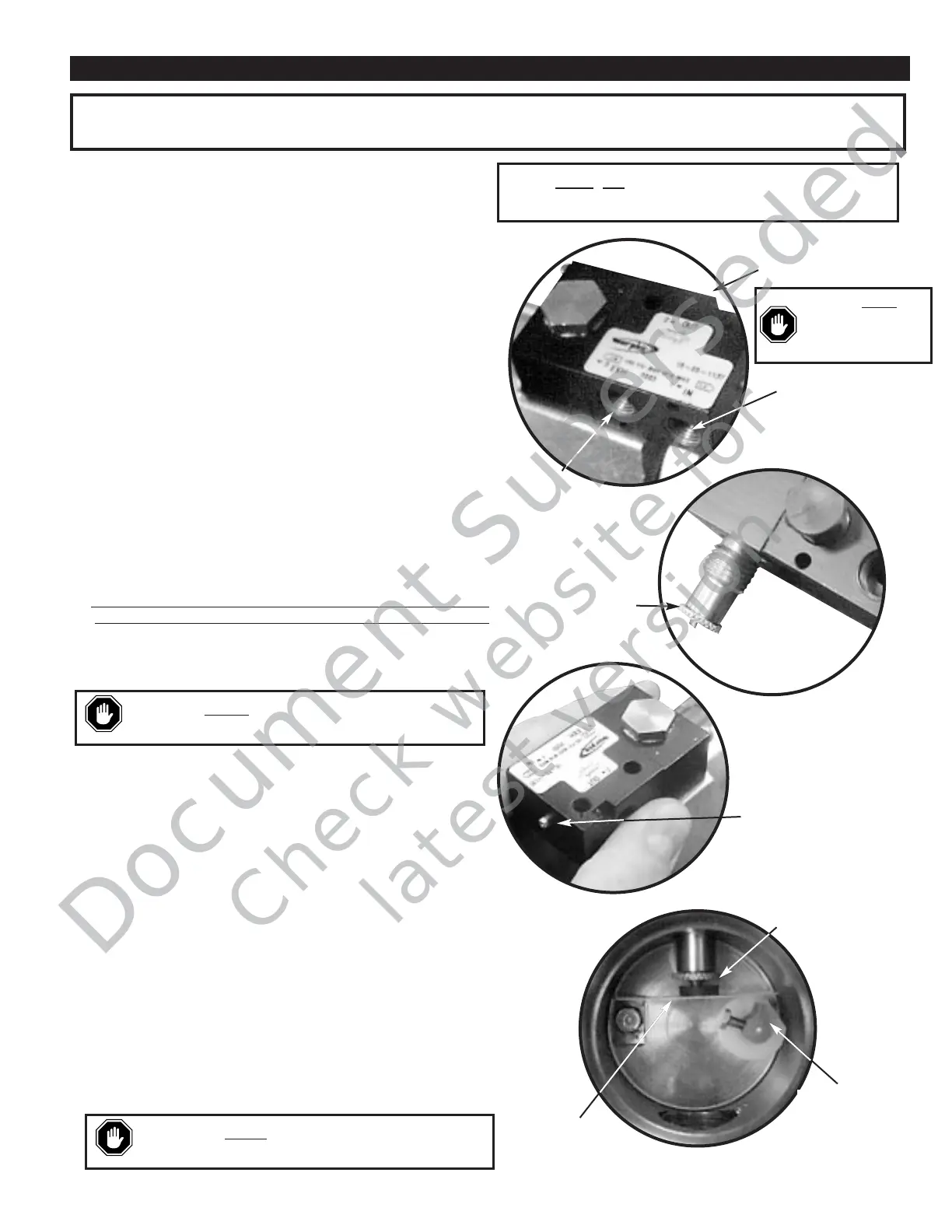

8. Ensure that the adjustable orifice is fully raised up to ensure

when inserted into the body that the actuator arm is not bent.

See fig 2.

9. Insert the new DVO onto the body. The DVO manual valve

operator must face away from the vessel.

10. With the DVO aligned over the hex on the LS200NDVO body,

tighten the valve using the 9/16" hex wrench. You may need to

hold the DVO while tightening to keep it from rotating. See fig 3.

11. The pneumatic input signal should be regulated between 30 and

70 psi for proper setting of the adjustable orifice. With the float

in the down position adjust the adjustable orifice down until it

touches the seat (see fig 4). If the DVO is still leaking make

slight adjustments (1/32 turn). Excessive adjustments will lock

up mechanisms. After adjusting make sure float moves freely

up and down.

12. Replace the LS200NDVO/DVOR cover.

13. Using the appropriate tools re-install the Inlet, Outlet, and

Exhaust fittings to the new DVO (see fig 1). Thread sealant is

recommended but care should be used to not allow excess to

enter valve.

14. If the LS200NDVO/DVOR was removed from the vessel re-

install it at this time. Thread sealant is recommended.

15. Connect to the Inlet, Outlet, and Exhaust fittings. According to

installation drawings.

When replacing/installing the DVO assembly, tubing and fitting modifications may be required. We suggest removing the LS200NDVO/DVOR

from the vessel. Relieve pressure from the vessel or use block valves before removing the LS200NDVO/DVOR.

CAUTION:

Ensure that the actuator arm is not bent

during assembly.

CAUTION:

LS200 series parts are not

interchangeable with the L1200 Series.

CAUTION:

LS200

series parts are not

interchangeable with

the L1200 Series.

NOTE:

Clean

,dry instrument quality gas should be used.

Use of filters will improve service life and reliability.

Outlet

Inlet

Exhaust

Figure 4

Figure 2

Replacing and Installing the DVO Assembly

For Models LS200NDVO & LS200NDVOR

Adjustable

Orifice

Figure 3

Orifice

Adjustment

Cam

(Not Adjustable)

Actuator Arm

(Not Adjustable)

Manual Valve

Operator

Figure 1

Loading...

Loading...