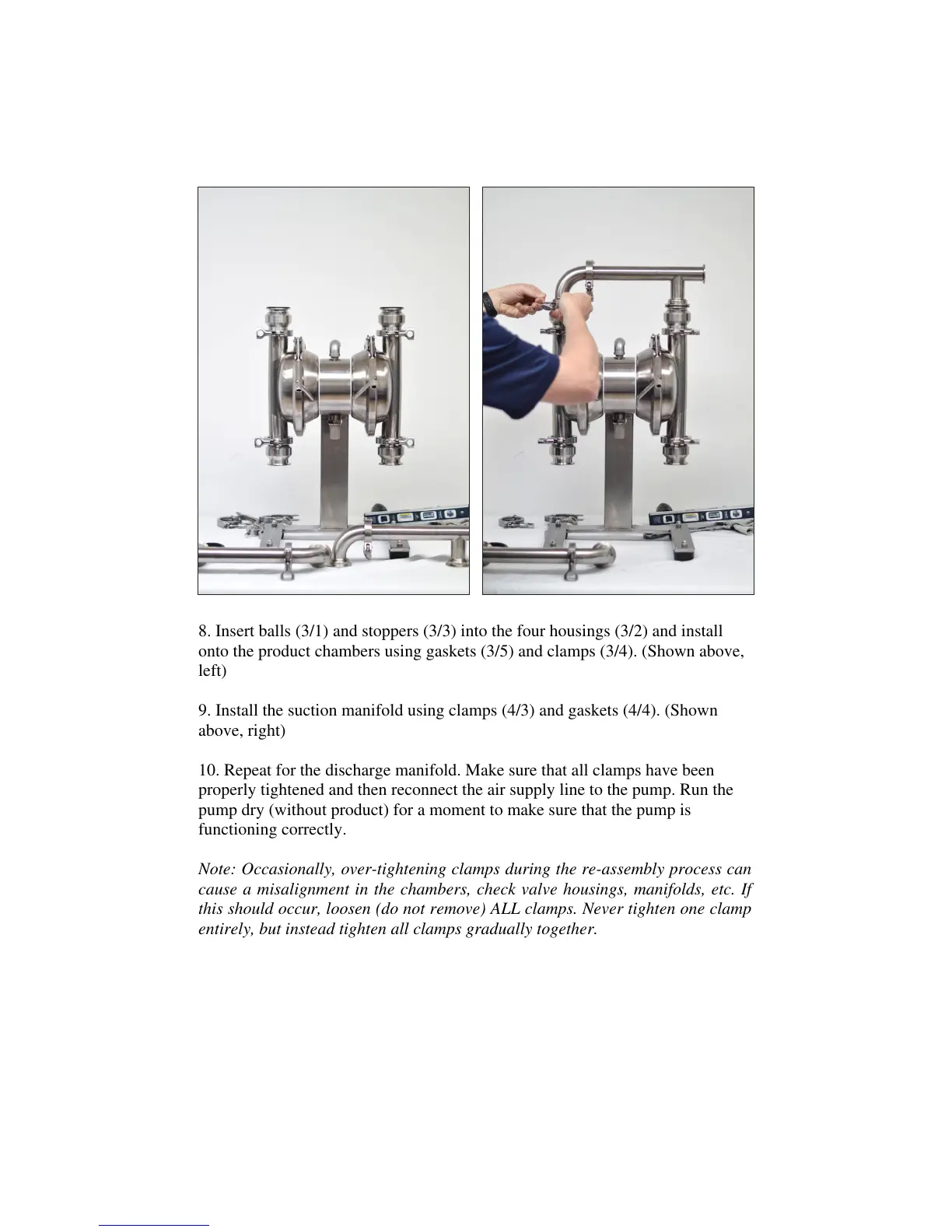

8. Insert balls (3/1) and stoppers (3/3) into the four housings (3/2) and install

onto the product chambers using gaskets (3/5) and clamps (3/4). (Shown above,

left)

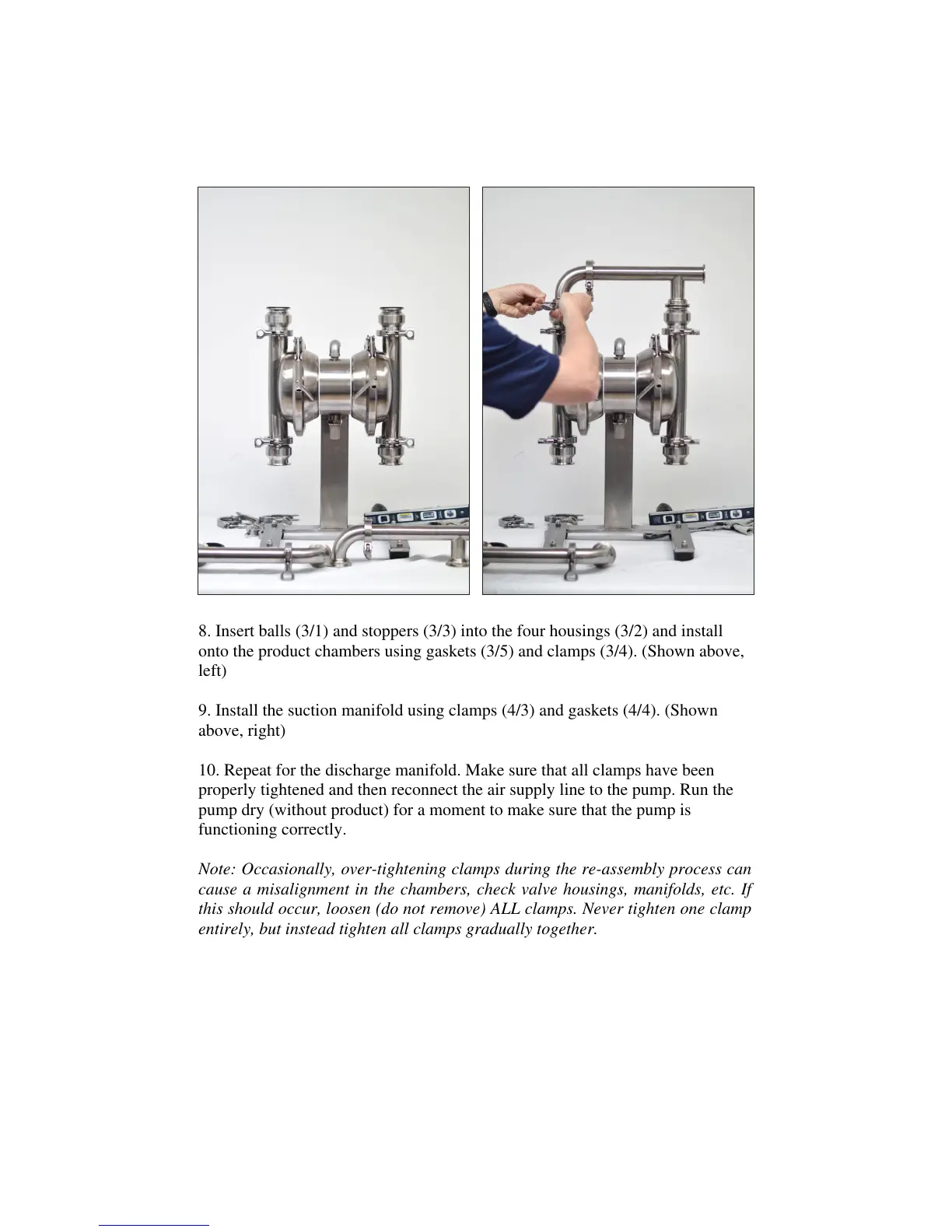

9. Install the suction manifold using clamps (4/3) and gaskets (4/4). (Shown

above, right)

10. Repeat for the discharge manifold. Make sure that all clamps have been

properly tightened and then reconnect the air supply line to the pump. Run the

pump dry (without product) for a moment to make sure that the pump is

functioning correctly.

Note: Occasionally, over-tightening clamps during the re-assembly process can

cause a misalignment in the chambers, check valve housings, manifolds, etc. If

this should occur, loosen (do not remove) ALL clamps. Never tighten one clamp

entirely, but instead tighten all clamps gradually together.

28

Loading...

Loading...