3.4Encoder reset and encoder

Encoder Correction procedure

Upon completion of the encoder

resetting, proceed with the encoder correction.

Press f9 <Encoder Correct>.

The screen which appeared immediately after [3 Machine Constants] [4 Encoder

Correction] were selected is restored.

Either "Data Input" or "Position Record" can be used as the method for encoder

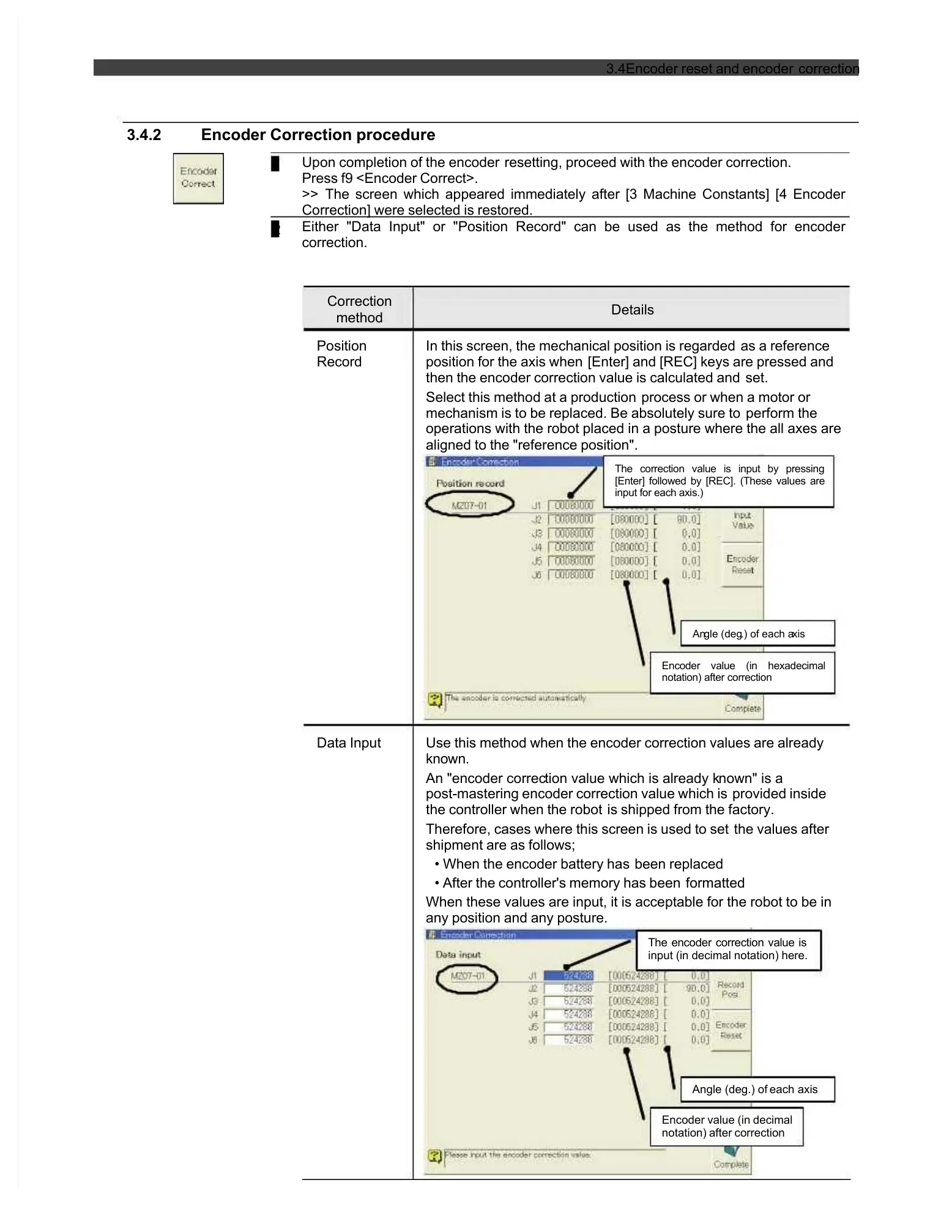

In this screen, the mechanical position is regarded

position for the axis when

[Enter] and [REC] keys are pressed and

then the encoder correction value is calculated and

Select this method at a production

process or when a motor or

mechanism is to be replaced. Be absolutely sure to

operations with the robot placed in a posture where the all axes are

aligned to the "reference position".

The correction value is input by pressing

[Enter] followed by [REC]. (These values are

Encoder value (in hexadecimal

notation) after correction

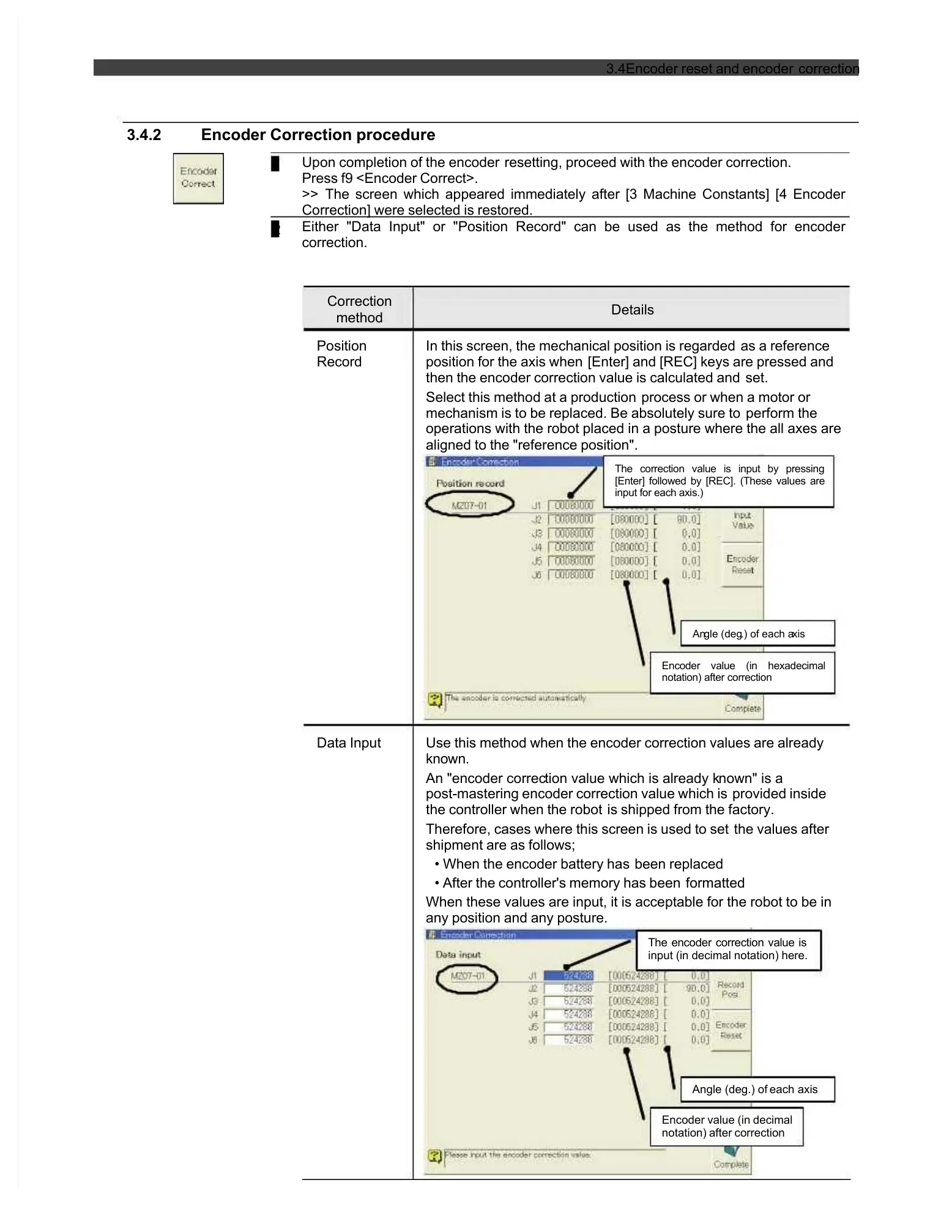

Use this method when the encoder correction values are already

tion value which is already k

post-mastering encoder correction value which is

the controller when the robot

is shipped from the factory.

Therefore, cases where this screen is used to set

• When the encoder battery has

• After the controller's memory has been

When these values are input, it is acceptable for the robot to be in

any position and any posture.

The encoder correction value is

input (in decimal notation) here.

Encoder value (in decimal

notation) after correction

Loading...

Loading...