3.4Encoder reset and encoder correction

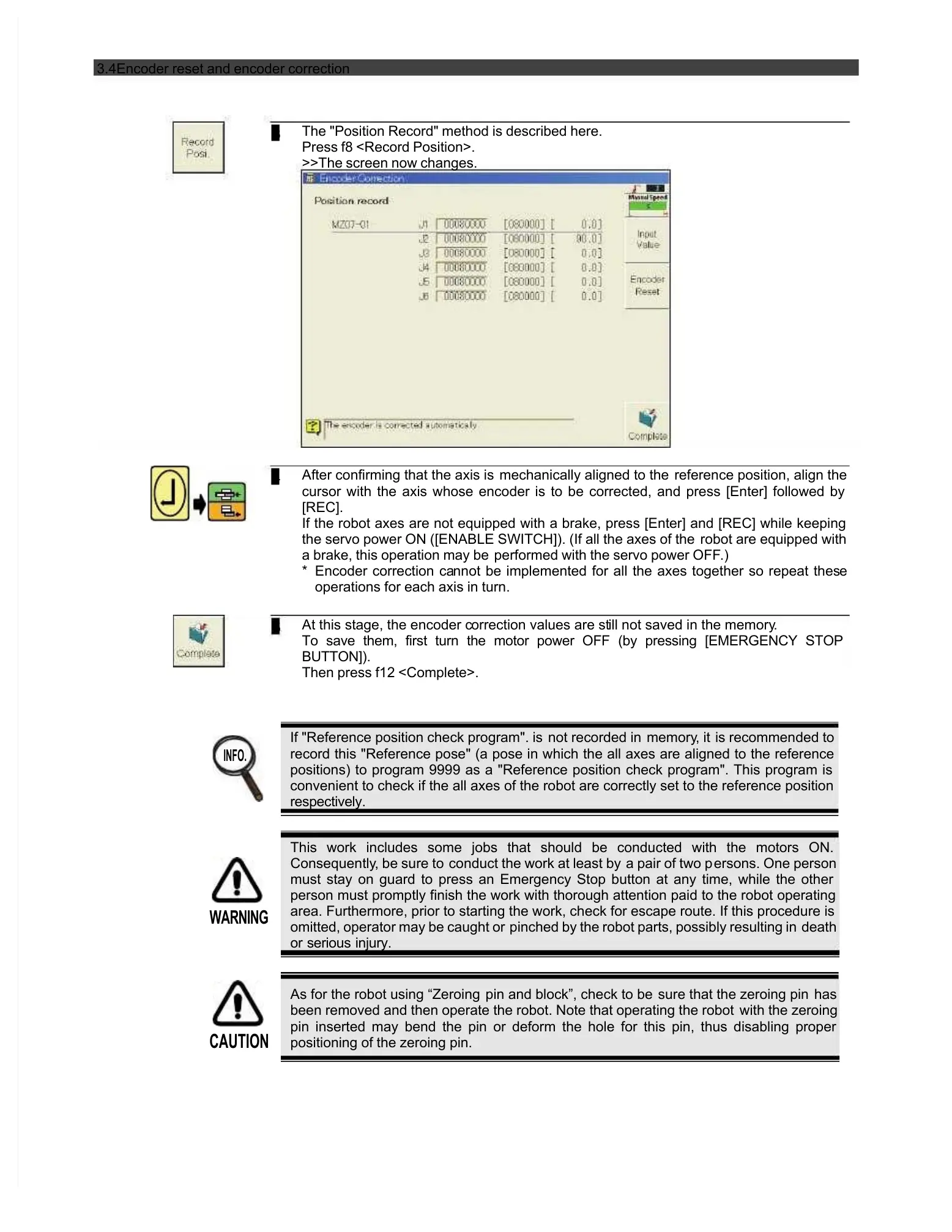

The "Position Record" method is described here.

Press f8 <Record Position>.

>>The screen now changes.

After confirming that the axis is

mechanically aligned to the

reference position, align the

cursor with the axis whose encoder is to be corrected, and press [Enter] followed by

If the robot axes are not equipped with a brake, press [Enter] and [REC] while keeping

the servo power ON ([ENABLE SWITCH]). (If all the axes of the

a brake, this operation may be

performed with the servo power OFF

nnot be implemented for all the axes together so repeat thes

operations for each axis in turn.

At this stage, the encoder c

ill not saved in the memory

To save them, first turn the motor power OFF (by pressing [EMERGENCY STOP

Then press f12 <Complete>.

If "Reference position check program". is

record this "Reference pose" (a pose in which the all axes are aligned to the reference

positions) to program 9999 as a "Reference position check program". This program is

convenient to check if the all axes of the robot are correctly set to the reference position

This work includes some jobs that should be conducted with the motors ON.

conduct the work at least by

must stay on guard to press an Emergency Stop button at any time, while the other

person must promptly finish the work with thorough attention paid to the robot operating

area. Furthermore, prior to starting the work, check for escape route. If this procedure is

omitted, operator may be caught or

pinched by the robot parts, possibly resulting in

As for the robot using “Zeroing

pin and block”, check to be

sure that the zeroing pin

been removed and then operate the robot. Note that operating the robot

pin inserted may bend the pin or deform the hole for this pin, thus disabling proper

positioning of the zeroing pin.

Loading...

Loading...