3.5 Tool constant settings

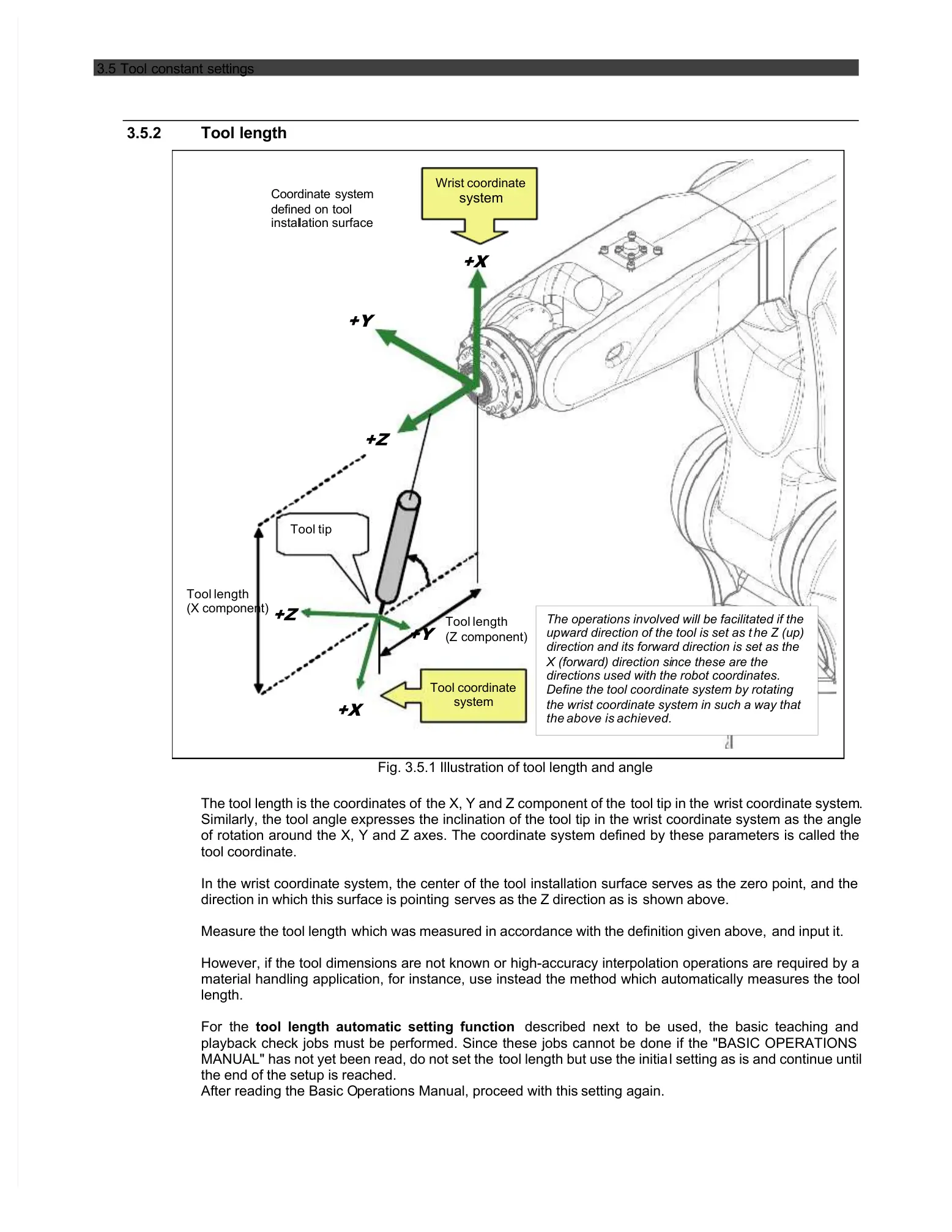

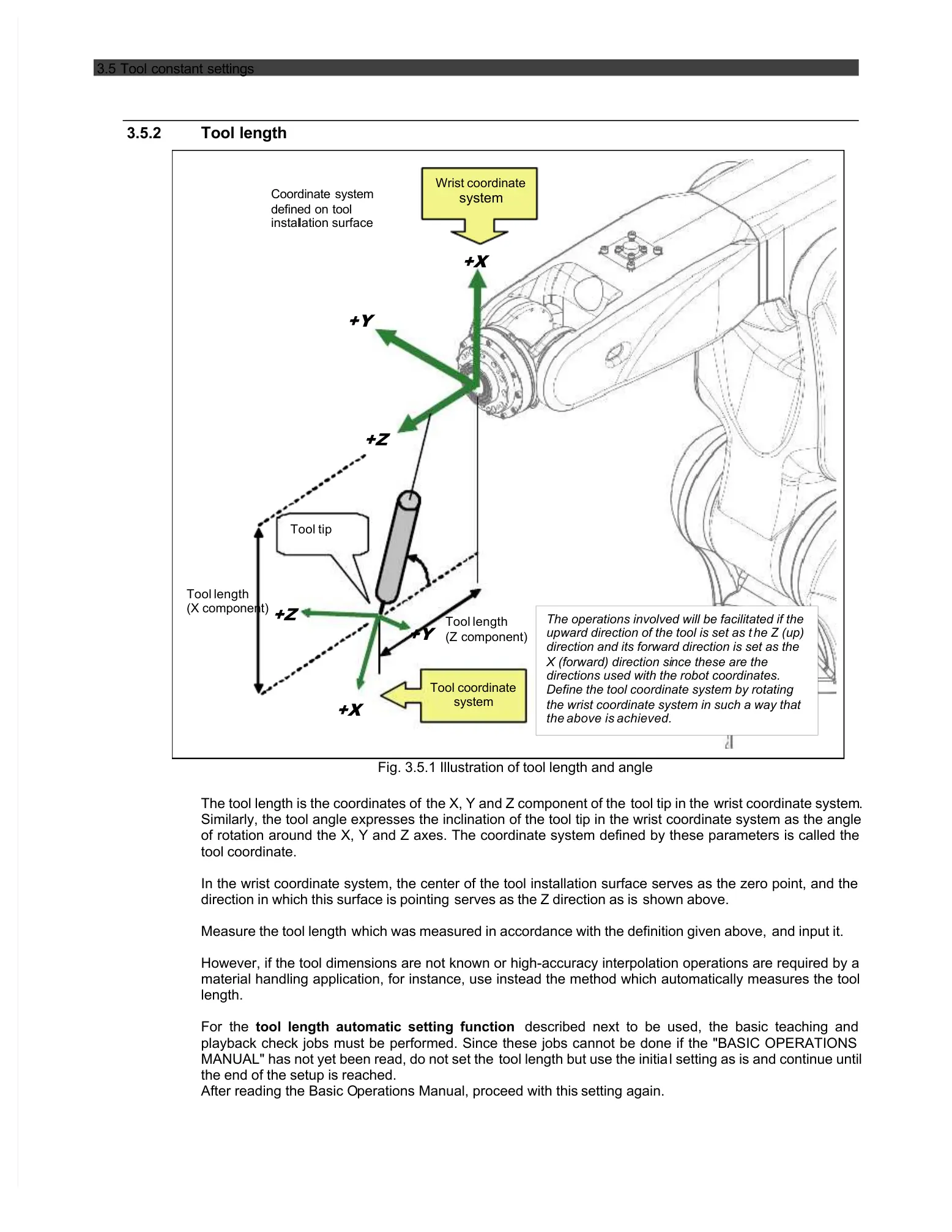

The operations involved will be facilitated if the

upward direction of the tool is set as t

direction and its forward direction is set as the

X (forward) direction si

directions used with the robot coordinates.

Define the tool coordinate system by rotating

the wrist coordinate system in such a way that

Fig. 3.5.1 Illustration of tool length and angle

The tool length is the coordinates of

the X, Y and Z component of the

Similarly, the tool angle expresses the inclination of the tool tip in the wrist coordinate system as the angle

of rotation around the X, Y and Z axes. The coordinate system defined by these parameters is called the

In the wrist coordinate system, the center of the tool installation surface serves as the zero point, and the

direction in which this surface is pointing

serves as the Z direction as is

which was measured in accordance with the definition given above,

However, if the tool dimensions are not known or high-accuracy interpolation operations are required by a

material handling application, for instance, use instead the method which automatically measures the tool

tool length automatic setting function

described next to be used, the basic teaching and

playback check jobs must be performed. Since these jobs cannot be done if the "BASIC OPERATIONS

MANUAL" has not yet been read, do not set the

tool length but use the initia

l setting as is and continue until

the end of the setup is reached.

After reading the Basic O

perations Manual, proceed with this

Loading...

Loading...