NEUTON Battery-Powered Chain Saw -

Safety & Operating Instructions

7

• Allow the Chain to cut for you; exert only light downward pressure. If you

force the cut, damage to the Bar, Chain, or unit can result.

• Do not put pressure on the Saw at the end of the cut.

• Do not cut above chest height, as a Saw held higher is difficult to control

against Kickback forces.

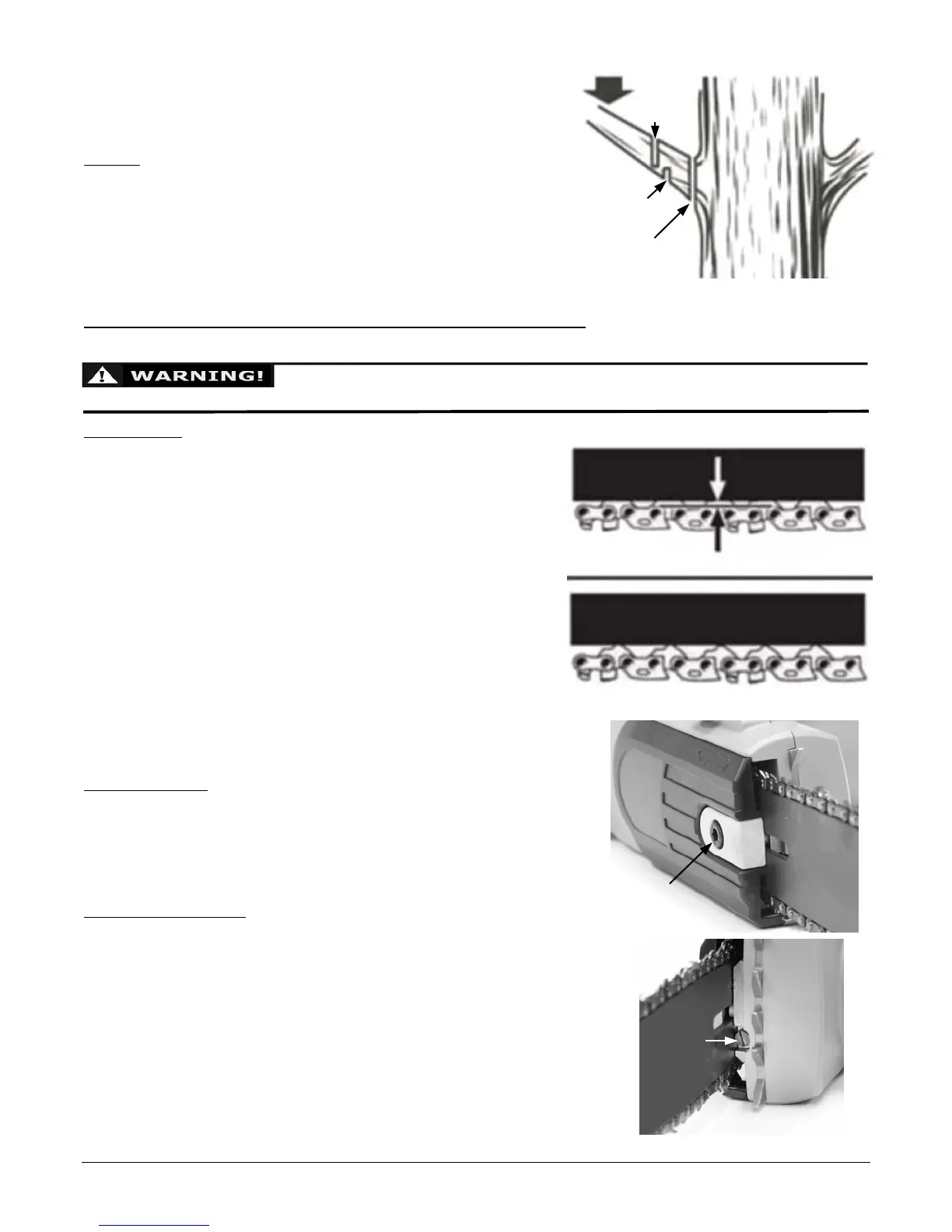

Pruning

•

When pruning trees it is important not to make the finishing cut next to the

main limb or trunk until you have cut off the limb further out to reduce the

weight. This prevents stripping the bark from the main member.

• Under cut the branch

1/3

through for your first cut. Your second cut should

over cut to drop the branch

off (

Figure 5)

.

• Now make your finishing cut from the topside of the branch smoothly and

neatly against the main member so the bark will grow back to seal the wound.

Chapter 4: Maintaining Your NEUTON Battery-Powered Chain Saw

This chapter explains how to adjust the Chain Tension, sharpen the Chain and Guide Bar Maintenance.

Always remove the Battery Pack before performing any adjustments, maintenance, or repairs to your Chain Saw.

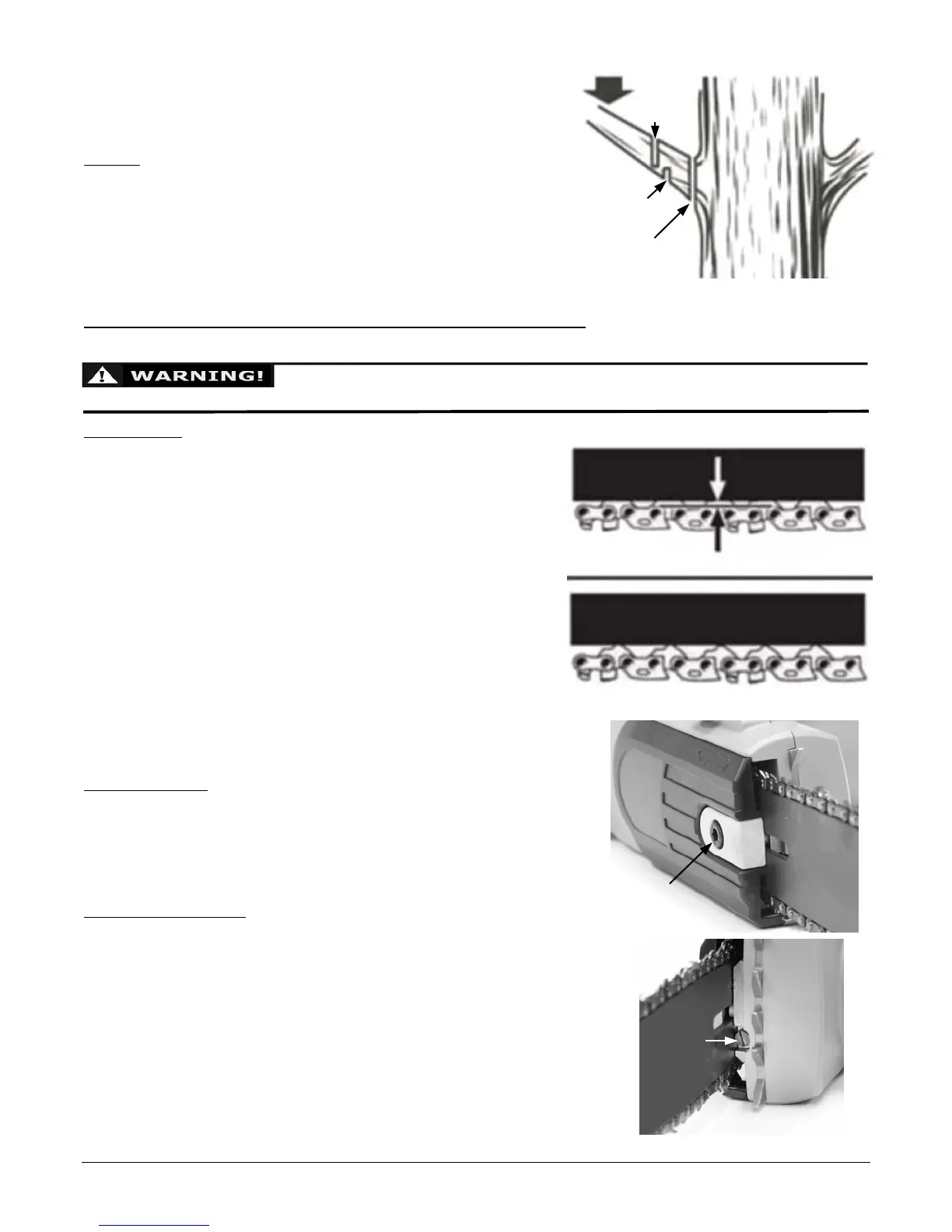

Chain Tension

Check the Chain Tension before using the Saw when the Chain is cold. The

correct tension of a cold Chain is when there is no slack on the underside of the

Guide Bar, the Chain is snug, but you can turn it by hand without binding.

During normal Saw operation, the temperature of the Chain will increase. The

Drive Links of a correctly tensioned warm Chain will hang approximately .050 in.

(1.25mm) out of the Bar Groove (Figure 6). Be aware that a Chain tensioned while

warm, may be too tight upon cooling. Check the "cold tension" before next use.

The Chain must be re-tensioned whenever the Flats on the Drive Links hang out

of the Bar groove (Figure 6).

NOTE: A new Chain tends to stretch so check the Chain tension frequently and re-

tension as required.

Tool Required:

• 7/32" Hex Key Wrench/ Blade Screwdriver (supplied)

1. Using the Hex Key Wrench, loosen the Guide Bar Screw (Figure 7) so it is just

finger tight.

2. Turn the Chain Tensioner (Figure 8) clockwise with a Screwdriver to tension

the Chain as required and then retighten the Guide Bar Screw.

Chain Sharpening

For smooth and fast cutting, you need to maintain the Chain properly. The Chain

requires sharpening when the wood chips are small and powdery, if you must

force the Chain through the wood during cutting, or the Chain cuts to one side.

NOTE: Improper Chain sharpening increases the risk of Kickback. Therefore, we

highly recommend that when the Chain requires sharpening, you have the

Chain professionally sharpened.

Guide Bar Maintenance

When the Guide Bar shows signs of wear, turn it over on the Saw to distribute the

wear for maximum Bar life. Feathering or burring of the Bar Rails is a normal

process of Bar wear. You should smooth such faults with a file as soon as they

occur.

Replace a Bar with any of the following faults:

• Wear inside the Bar Rails permitting the Chain to layover sideways.

• Bent Guide Bar

• Cracked or broken Rails

• Spread Rails

Turn the Saw over, check the underside of the Guide Bar, and make sure that the

lubrication holes and Chain Groove are free from impurities.

Load

First Cu

1/3 Diameter

Second Cu

inishing Cu

Figure 5

Properly Adjusted Warm Chain

pproximately .050 in. (1.25mm)

Chain Needs Tensioning

Figure 6

Figure 7

Figure 8

Guide Bar Scre

Chain

Tensioner

Loading...

Loading...