Fitting your Pump

6

NEWTEAM SHOWER PUMPS

Duraspeed & Duraspeed 2

Flexible connectors should not be bent. Where possible keep all flexible

connectors vertical.

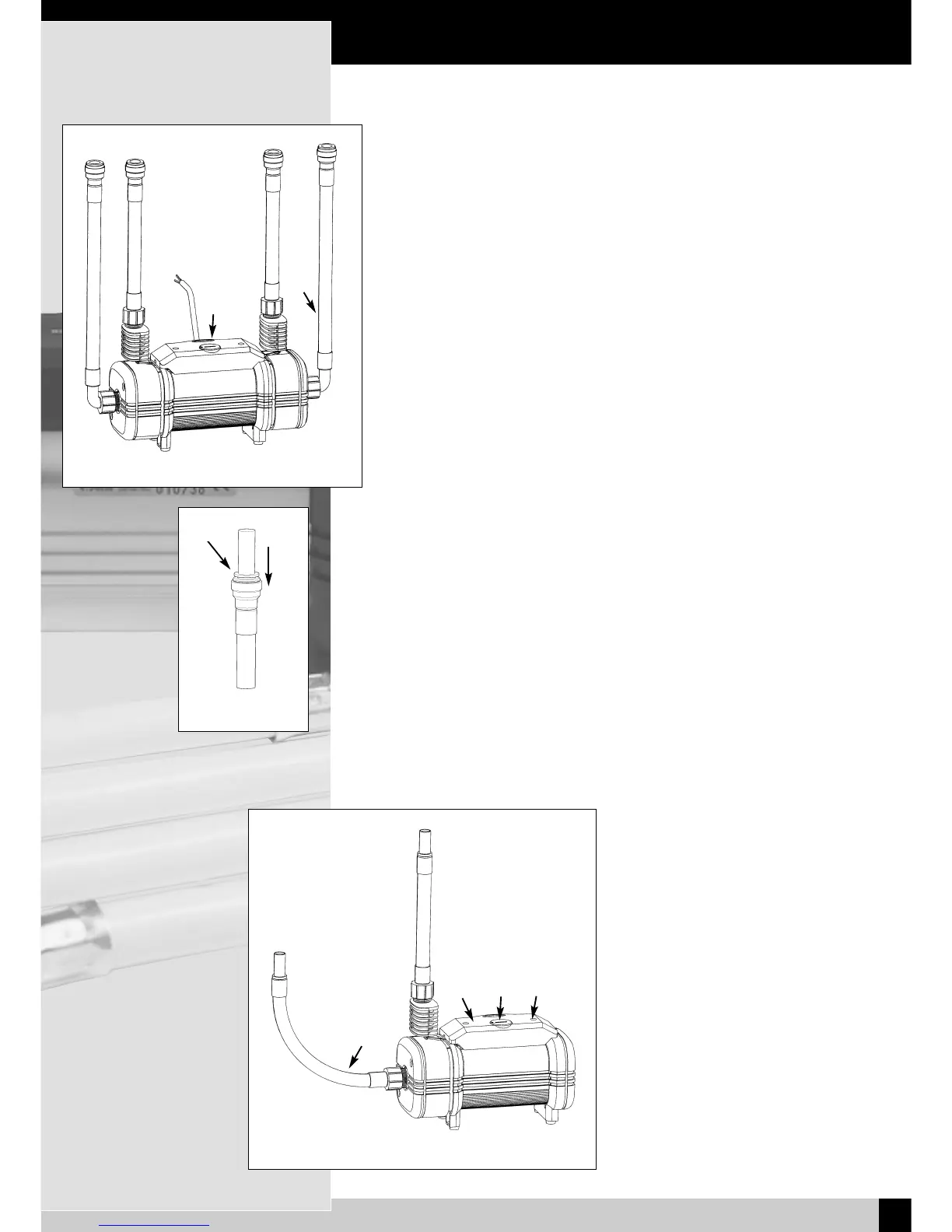

1. Connect the flexible connectors (1) supplied to the inlet and outlet ports of

the pump. Ensure that the adaptors fitted to the inlets have filters in

position.

NOTE: These are designed to effect a leakproof seal with the minimum of

tightening. Hand tight is sufficient, the elbow flexible connectors should be on

the inlets.

Ensure not to kink the flexible hoses.

• Either end inlet can be used for hot or cold.

IMPORTANT: The integral fittings on the hose are of the push fit type. All

burrs and rough edges must be removed from the end of the pipe. In the

case of a chrome-plated tube, the first 25mm of plating should be

roughened or removed. Should it be necessary to remove the pipe after

installation, push down the grey collet. (Fig 5a)

2. Connect fitted flex into fused spur outlet, in accordance with the ‘Electrics’

chapter.

3. Either by hand or using a coin, rotate boost control (2) fully anti-clockwise, to

maximum mark.

WARNING: Do not fit fuse or switch on mains electrical supply at this point

Varispeed SI

Flexible connectors should not be bent more than 90°. Where possible keep

all flexible connectors vertical.

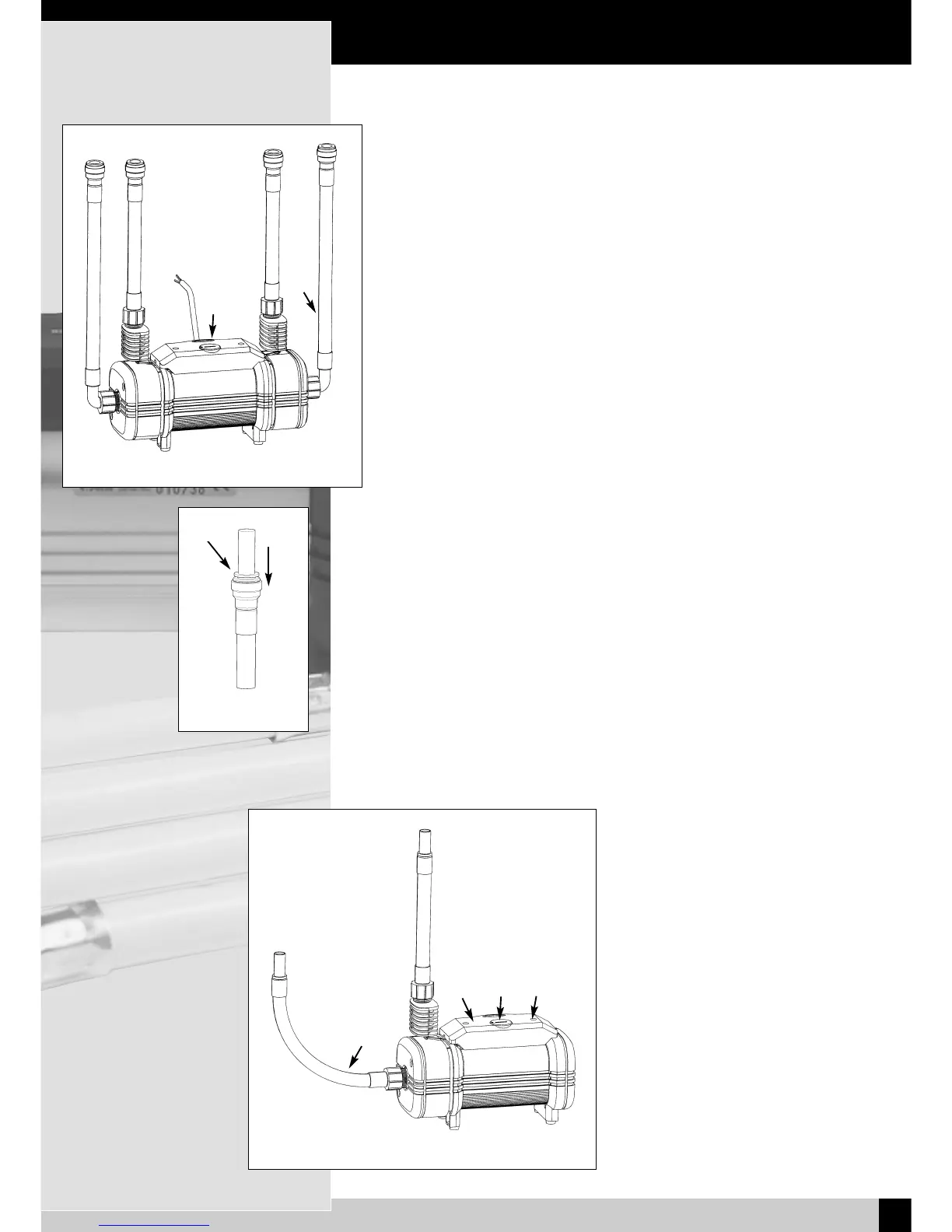

1. Connect the flexible connectors (1) supplied to the inlet and outlet ports of the

pump. Ensure that the adaptors fitted to the inlet have a filter in position.

NOTE:This is designed to effect a leakproof seal with the minimum of tightening.

Hand tight is sufficient, the long flexible connector should be on the inlet.

Ensure not to kink the flexible hoses.

Fig. 5. Diagram of Duraspeed/Duraspeed 2

1

2

Fig. 5a.

Pushfit Connectors

Collet

Fig. 6. Diagram of the Varispeed SI

1

2

3

4

IMPORTANT: The hoses supplied

with the Varispeed SI should only be

connected with compression

fittings. Under no circumstances

should solder fittings be used.

2. Connect the cable connected to the

pump to the electric supply, please

refer to the electric section, page 4.

3. Either by hand or using a coin, rotate

boost control (2) fully anti-clockwise,

to maximum mark.

WARNING: Do not fit fuse or switch

on mains electrical supply at this

point.

Loading...

Loading...