Mounting Instructions EN

MA-CFB_BEARING 4.4 – 02/2020 5

Self-aligning bearing

with clamping sleeve and cast housing

RZR 13-0400/-1600 (IWN)

RER 13-0200/-1600 (IWN)

RER 17-0200/-1000 (IWN)

(Page 1 of 3)

Notes

The built-in self-aligning bearings with clamping sleeve are designed for a nominal service life (L

10h

according to DIN ISO 281-

1) of 20,000 respectively 40,000 operating hours. Maintenance must be carried out according to the chapter on

upkeep/maintenance in the RZR / RER operating instructions. If it is required to change the bearings, the safety

instructions stipulated in the RZR / RER operating instructions must be followed without fail!

General information

To expose the fan bearings, various dismounting work (e.g. disconnection from the mains, belt drive, protective and

monitoring devices, ducts),must be performed in compliance with the safety and accident protection regulations and the local

and structural conditions.

Dismounting the bearing

1. Dismount bearing housing cover (1)

2. Bend up the safety plate of the sleeve nut and unscrew the sleeve nut (2) (approx. 2-3 rotations) until the front face is flush

with the clamping sleeve.

3. Set blow cap or pipe section against the sleeve nut and loosen the clamping sleeve with jarring blows axial and radial

released bearings can also be hammered from the clamping sleeve.

4. Unscrew fastening screws on the bottom part of the bearing housing

5. Prop and secure running wheel or shaft

6. Remove the bottom part of the bearing housing with the bearing off the shaft.

Mounting the bearing

The bearings are accordingly mounted in the reverse order, it must be ensured that the components are absolutely clean

- Centre the covering of the inlet ring and running wheel

Caution!

Do not switch or twist the upper and lower parts of the cast casing! Mark the upper and lower shell before

dismounting

1. Designate one of the bearing as a fixed bearing by fitting a fixed ring, preferably on the drive side.

Caution!

Do not insert any fixed rings on the floating bearing side!

2. The bearing clearance must be set at the same time that the bearing is fastened to the shaft. To ensure that the

bearing lifespan is long, special care must be taken here!

In order to avoid premature damage, please note the following:

Do not subject the bearing mounting to knocks and blows!

The tightening methods of the different manufacturers must not be interchanged!

Tighten the sleeve nut as per the following two steps:

- Step 1: The sleeve nut must be evenly tightened until the shaft, the sleeve and the inner ring of the bearing are as close

together as possible (interlocking) (look for the so-called "fixed point").

For FAG bearings this point is reached when the sleeve nut is tightened with a defined torque. To do this, you will however

need the special tool supplied by FAG. When using the “standard tool” other tightening torques than those for the original

FAG tool apply! (Note the differences in Table 2+3!)

- Step 2: Depending on the fan or the bearing size, the sleeve nut is tightened as stated in Table 2+3. As this process results

in the necessary bearing clearance, this process must be undertaken with care.

The procedures and tightening values must be observed as given by the bearing manufacturer. It is not permitted to

exchange one process for the other!

Only the approved tools must be used to tighten the locknut, e.g. hook spanner, hydraulic nut, etc. It is not permitted

to tighten the locknut with a mandrel or hammer and chisel!

3. Secure the sleeve nut (bend back a tab of the safety plate)

Caution!

Never turn sleeve nuts back to secure them! Always continue to turn them in the tightening direction until a tab of

one the nuts can be bent backwards.

4. Tighten the connecting bolts of the upper and lower part of the casing with the torque given in Table 2+3.

Lubrication

Lubrication must always be undertaken with the recommended quality lubricant (see the RZR / RER Operating Instructions).

- Fill the hollows of the self-aligning bearings completely with lubricant.

- Fill the bearing housing half (50%) with lubricant.

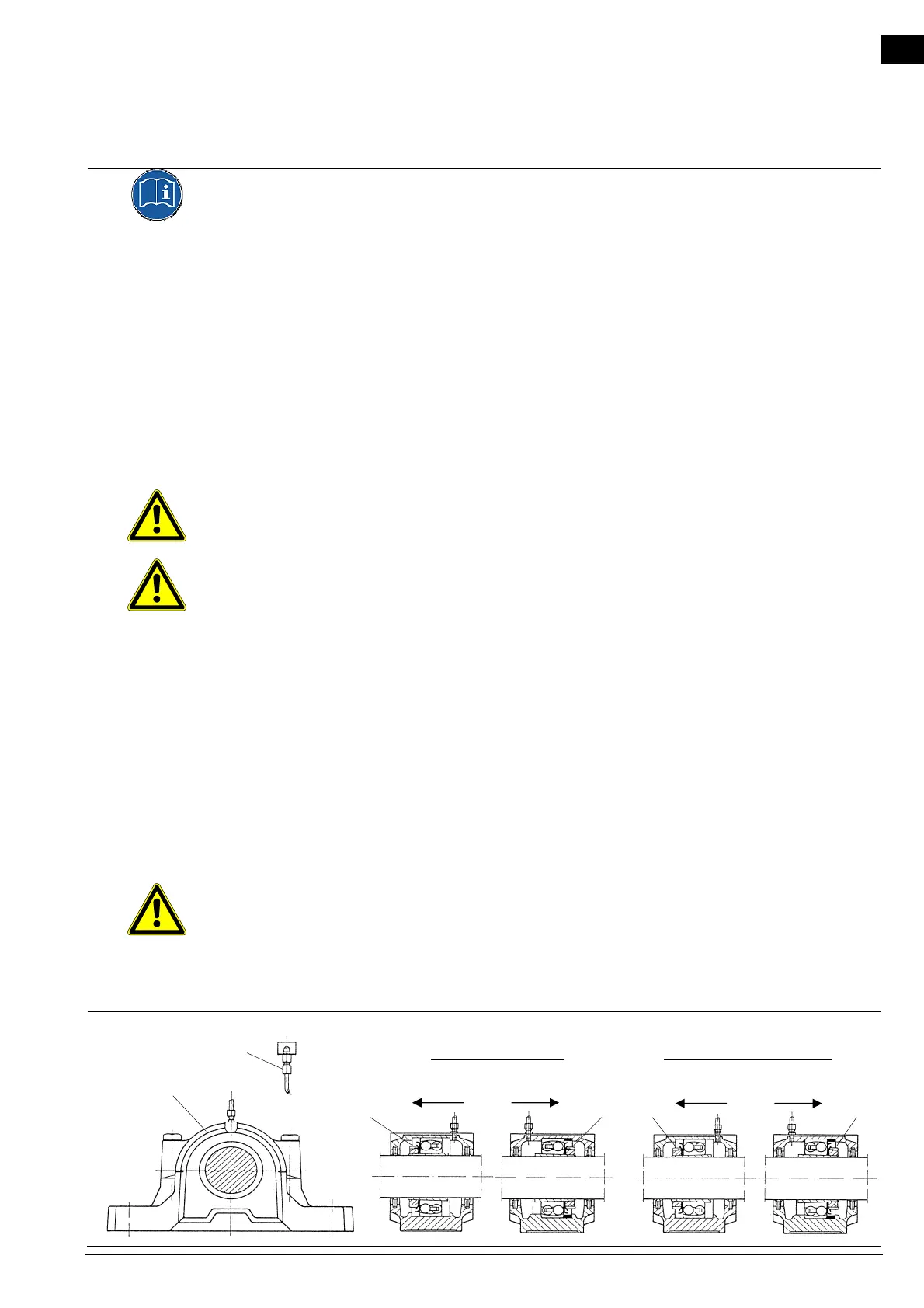

Standard and IWN

1

2 2

Only for IWN...

Bearing orientation RZR Bearing orientation RER 13/17

2 2

Loading...

Loading...