6

optimises the operation while making the quality control more efcient.

All Niviuk gliders go through an extremely thorough and detailed nal

inspection. The canopy is cut and assembled under strict quality control

conditions facilitated by the automation of this process.

Every wing is individually checked with a nal visual inspection.

The fabric used to manufacture the glider is light, resistant and durable.

The fabric will not experience fading and is covered by our warranty.

All lines are made from Technora with a polyester sheath.

The line diameter has been calculated depending on the workload and

aims to achieve the required best performance with the least drag. The

sheath protects the line cores from UV rays and abrasions.

The lines are semi-automatically cut to length and all the sewing is

completed under the supervision of our specialists.

Every line is checked and measured once the nal assembly is

concluded.

Each glider is packed following specic maintenance instructions as

recommended by the fabric manufacturer.

Niviuk gliders are made of premium materials that meet the requirements

of performance, durability and certication that the current market

demands.

Information about the various materials used to manufacture the wing

can be viewed in the nal pages of this manual.

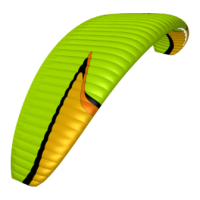

1.5 ELEMENTS, COMPONENTS

The HOOK 5 is delivered with a series of accessories that will greatly

assist you in the maintenance of your paraglider:

- A Kargo bag. This bag is large enough to hold all equipment

comfortably and with plenty of space.

- An inner bag to protect the wing during storage and transport.

- An adjustable compression strap to compress the inner bag and reduce

its volume.

- a speed-bar.

- A repair kit with self-adhesive Ripstop tape in the same colour as the

wing and spare parts to protect the maillons.

2. UNPACKING AND ASSEMBLY

2.1 CHOOSING THE RIGHT LOCATION.

We recommend unpacking and assembling the wing on a training hill or

a at clear area without too much wind and free of obstacles. It will help

you to carry out all the recommended steps required to check and inate

the HOOK 5.

We recommend the whole installation procedure is supervised by a

qualied professional instructor or ofcial dealer. Only they can address

any doubts in a safe and professional way.

2.2 PROCEDURE

Take the paraglider out of the rucksack, open and unfold it on the ground

with the lines positioned on the undersurface, oriented in the direction

of ination. Check the condition of the fabric and the lines for defects.

Check the maillons/IKS connecting the lines to the risers to make sure

they are fully closed and tightened. Identify, and if necessary untangle,

the A, B and C-lines, the brake lines and corresponding risers. Make sure

that there are no knots

2.3 CONNECTING THE HARNESS

The HOOK 5 risers are colour-coded.

- Right: green

- Left: red

This colour-coding makes it easier to connect the wing to the correct

side and helps prevent pre-ight errors.

Loading...

Loading...