Daily (Shift) Pre-Start Checklist

The following two page checklist should be used at the start of each working day (shift)

relevant to the area(s) of the Vacuum Machine that will be used during the working day. A

relevant section of the checklist may be filled out prior to the area of the machine being

used.

Vacuum Machine Location ______________________________ Date: __________

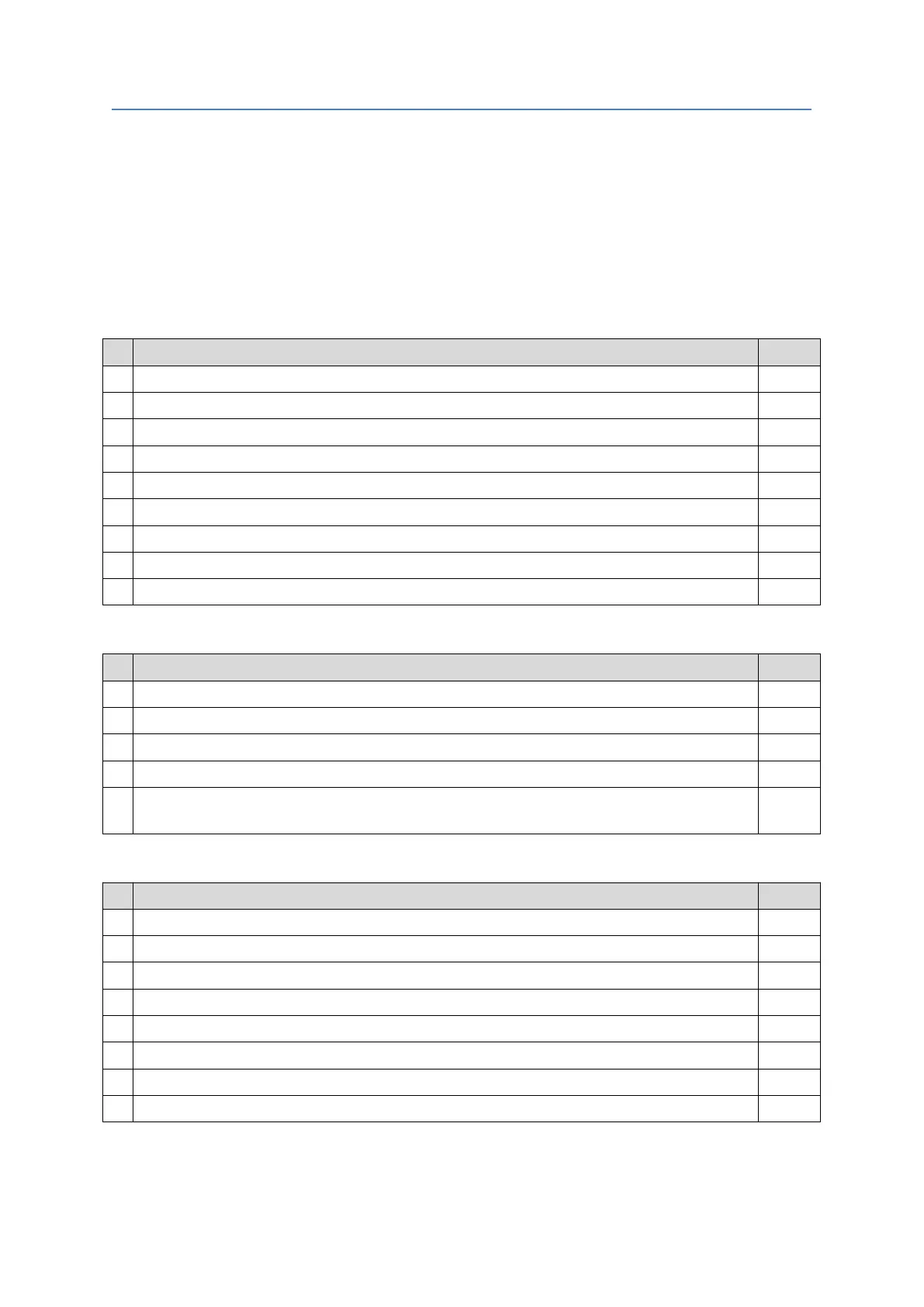

Pre-Start – Towing

# Pre-Start Check Requirement Initials

1 Check general condition of the trailer – no damage or protruding items – drum door closed.

2 Check tyres are correctly inflated and no visual damage to them.

3 Check wheel nut tightness – Tight turning the heavy trailer can cause the wheel nuts to loosen.

4 Check that the towing vehicle has a minimum of two (2) tonne towing capacity.

5 Check that towing vehicle has a standard diameter 50mm tow ball.

6 Connect trailer to vehicle – Check safety chains are secured and electrical connections made.

7 Check for correct operation of all trailer lights.

8 With vehicle handbrake applied, check that trailer handbrake is released & revering link removed.

9 Stow jockey wheel and wheel chocks correctly.

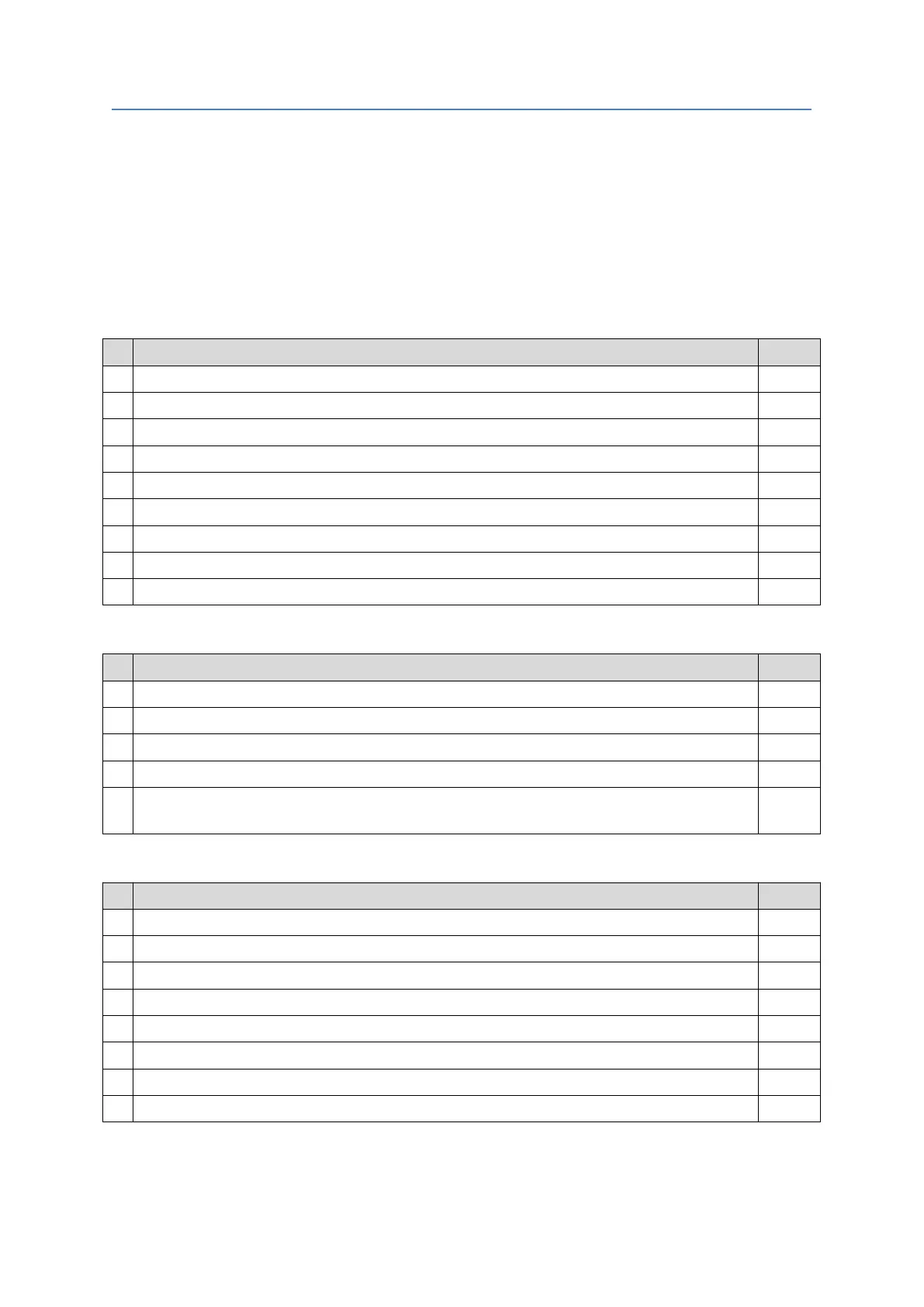

Pre-Start – Operational Set-Up

# Pre-Start Check Requirement Initials

1 Check that trailer handbrake is applied and wheel chocks installed.

2 Ensure that trailer operation angle does not exceed 20 degrees in any direction.

3 Check that the operational environment is not in an enclosed or partially enclosed building.

4 Plan where the removed material will be dumped.

5 Check that the planned material to be removed is not acidic, caustic, combustible, flammable,

toxic or hazardous material such as asbestos etc.

Pre-Start – Water Blaster

# Pre-Start Check Requirement Initials

1 Check that the water tank has sufficient water in it.

2 Check for correct oil level on the water pump – look at sight glass.

3 Check the condition of the water pressure hose – no damage or kinks

4 Check the condition of the water blaster wand & nozzle. Do not inspect whilst connected to hose.

5 Check that the quick connect functions correctly.

6 Visual checks for water leaks in hoses from water tank to pump.

7 Clean water filter if required.

8 Operator is competent to use the water blaster.

20

Loading...

Loading...