4

5.Adjustment method (Refer to P. 23 and after of operation manual)

<Kind of feedback modes at time of driving>

Feedback control operations at time of driving of K-ECG25 are following three kinds:

(A) Constant voltage mode:

This is a mode generally used (Initial setting at the time of shipment). It

controls the constant voltage so that the load (output) voltage becomes the

value set by the speed adjustment knob.

(B) Constant amplitude mode: Select this mode when the weight variation of work is large or more

stable feeding operation is required.

(C) Resonance point tracking mode: To drive more efficiently, this controls so that the amplitude

becomes steady at the resonance point of parts feeder. In the resonance

point tracking mode, the constant amplitude control also becomes ON at

the same time.

Note) Before adjusting each mode, please confirm that all wirings ended and there is no work in the bowl or

on the chute, and then set functions of J01 and J04. Moreover, before adjusting the constant amplitude

mode and resonance point tracking mode, please install vibration sensor and set function J06 and J07

with the resonance point tracking mode.

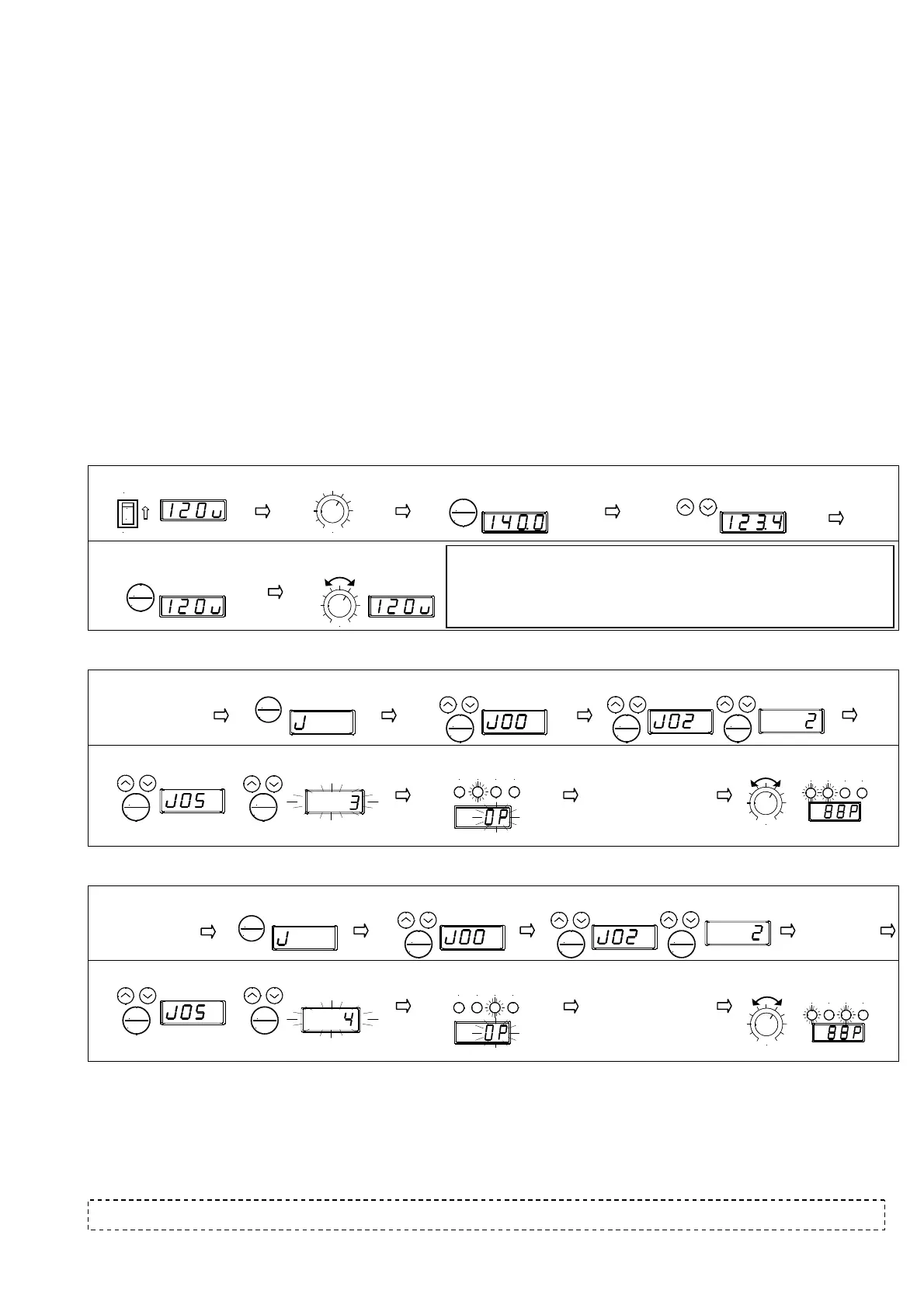

(A)Adjustment method of constant voltage mode (Refer to P. 26 of operation manual)

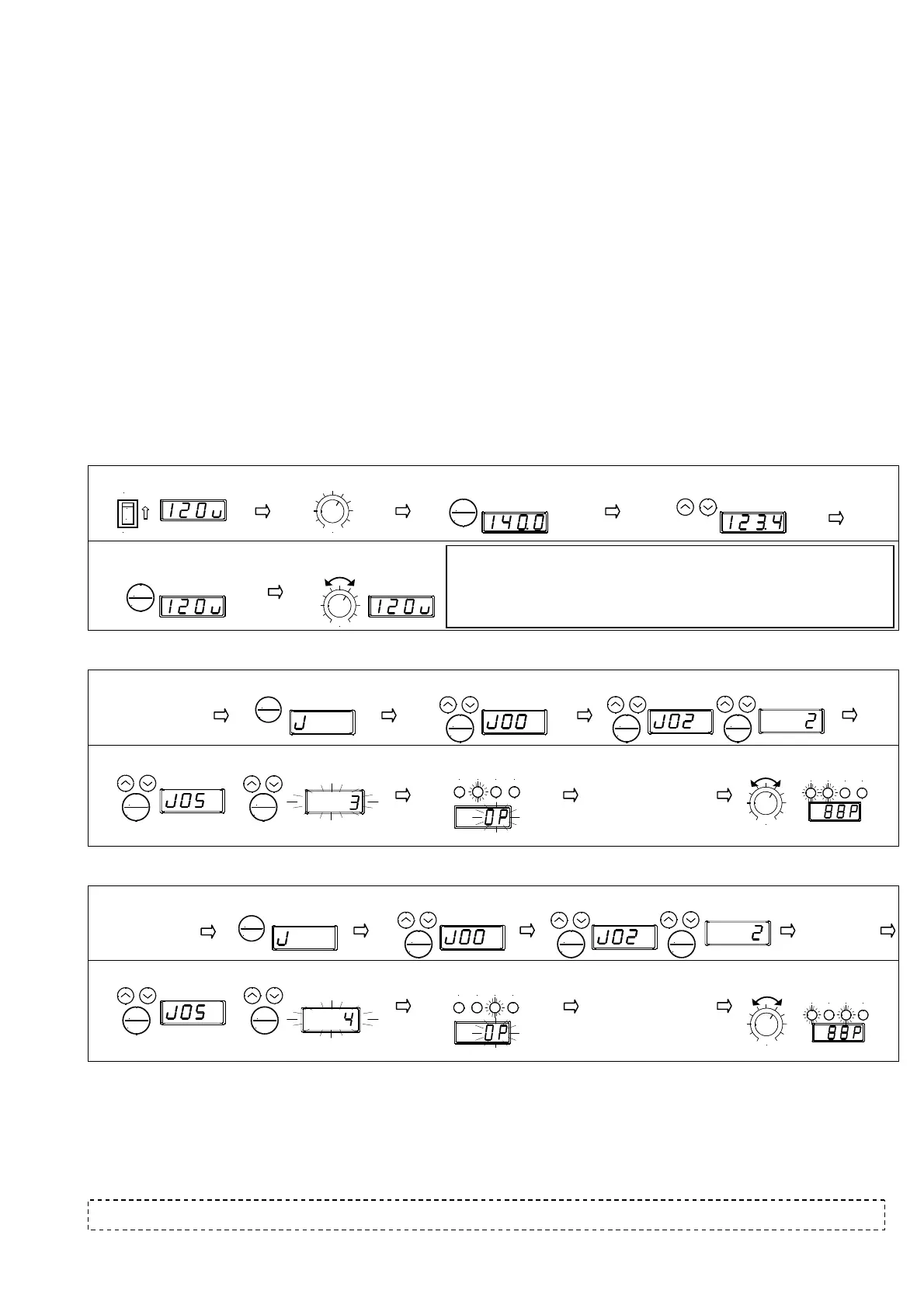

(B)Adjustment method of constant amplitude mode (Refer to P. 28 of operation manual)

(C)Adjustment method of resonance point tracking mode (Refer to P. 31 of operation manual)

Refer to operation manual for details of driving and adjustment.

6.Trouble shooting

In the event that any trouble occurs, please refer to P. 54 to 56 of operation manual.

Revised July 1, 2013 4th edition

NTN Technical Service Corporation

Contact: East Japan district (Tokyo) 03-6713-3652 Central Japan district (Nagoya) 052-222-3291 West Japan district (Osaka) 06-6449-6716

OFF

ON

O

I

SPEED

①Power ON (in operation)

②Knob scale: about 5

③Data one push (Frequency displayed )

④Frequency adjustment (set slightly higher than resonance

point)

※Points for frequency adjustment

Max. amplitude point (resonance point) of the part feeder is searched lowering the

frequency from the initial value (ECG25:140Hz,ECJ45:70Hz)gradually with the down key.

After that, drive by

frequency (3~10Hz) slightly higher than resonance point. Then vibration

becomes stead

.

SPEED

⑥ Adjust amplitude with knob

⑤ Data push twice (Voltage display)

DATA

ENTER

DATA

ENTER

SPEED

RUN Vib.

Fre.A LIMIT

RUN Vib.A Fre.A LIMIT

⑦ Return J02 to the

original state or push

the RUN key to driving

state.

②Function long push

③Select function J

④ Select J02 and then select 2 (Stopping state)

①Implement ①~④ of constan

voltage mode

⑤Select J05 then select 3 (Calibration begins)

⑥Calibration ends

⑧Adjust amplitude with knob

Gain is automatically adjusted

FUNC

RESET

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

RUN Vib.A Fre.

LIMIT

①Implement の of

constant voltage

mode

⑥Select J05 then select 4 (Calibration begins)

SPEED

RUN Vib.A Fre.A LIMIT

fter automatic search of resonance frequency,

gain is automatically adjusted.

②Function long push

⑤Set J04, J06 and

J07

③Select function J

④Select J02 then select 2 (Stopping state)

⑦Calibration ends

⑧ Return J02 to the

original state or push

the RUN key to driving

state.

⑨Adjust amplitude with knob

FUNC

RESET

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

DATA

ENTER

Loading...

Loading...