MODEL: SFL618

NOTE:

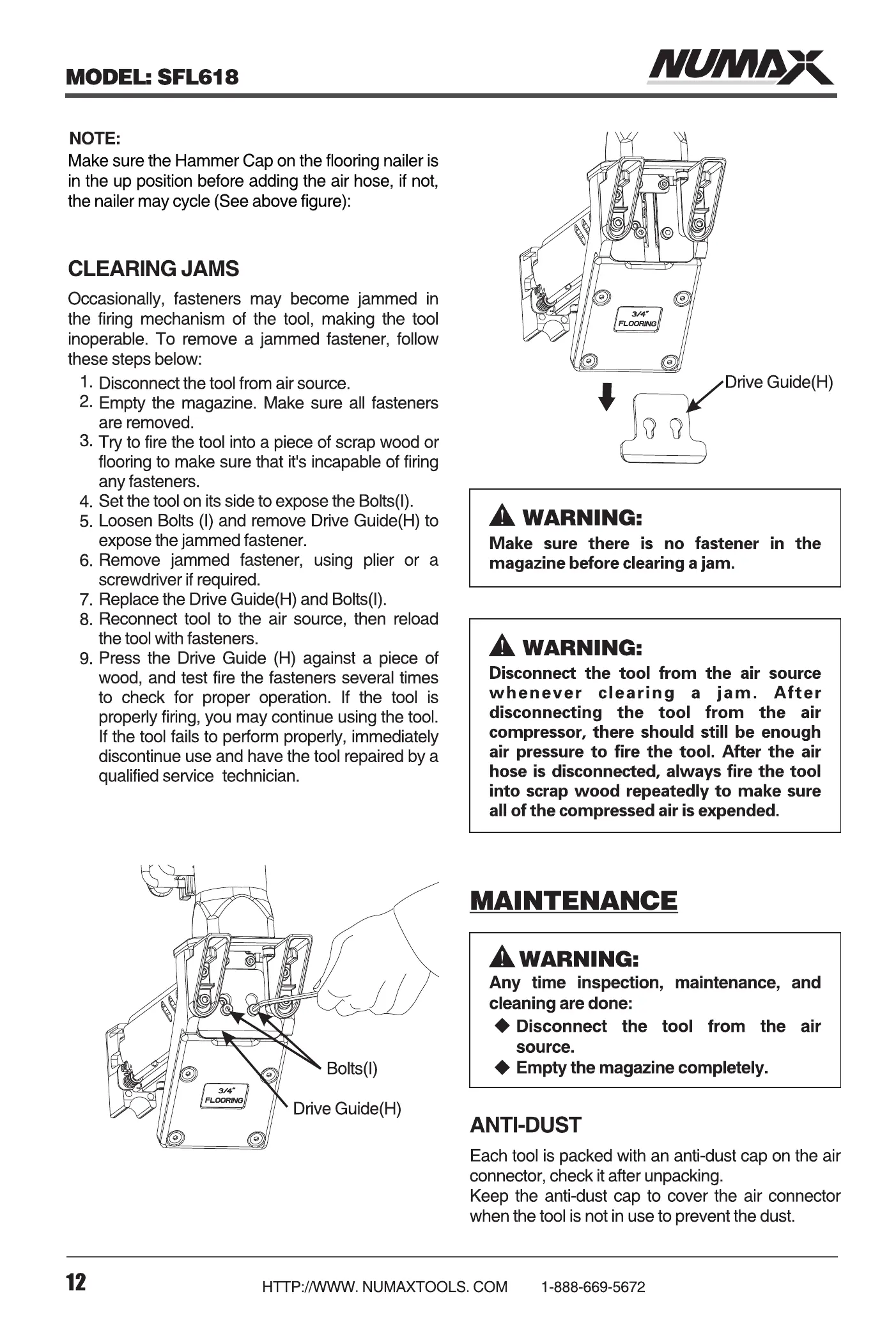

Make sure the Hammer Cap on the flooring nailer is

in the up position before adding the air hose, if not,

the nailer may cycle (See above figure):

CLEARING JAMS

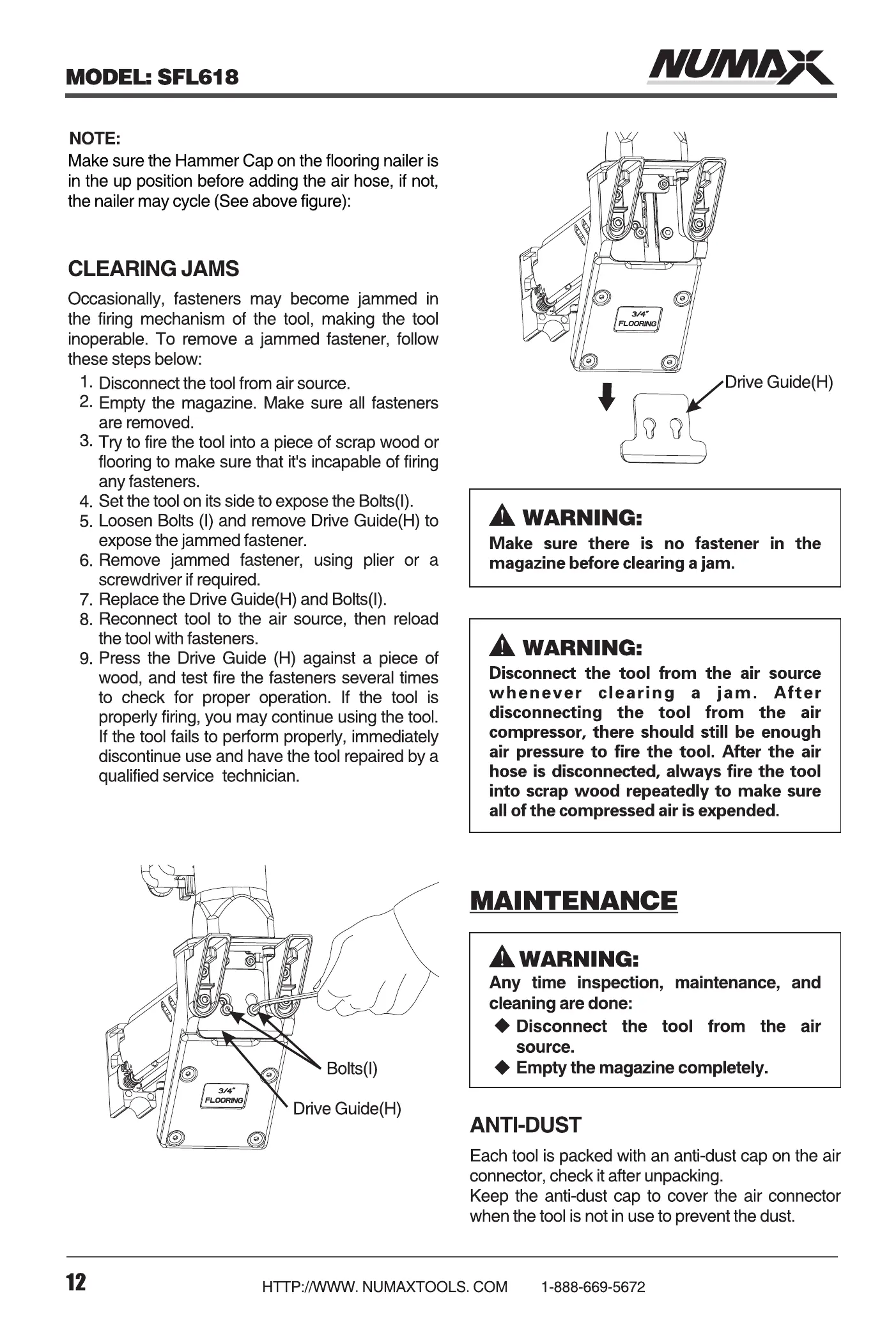

Occasionally, fasteners may become jammed in

the firing mechanism of the tool, making the tool

inoperable. To remove a jammed fastener, follow

these steps below:

1. Disconnect the tool from air source.

2. Empty the magazine. Make sure all fasteners

are removed.

3. Try to fire the tool into a piece of scrap wood or

flooring to make sure that it's incapable of firing

any fasteners.

4. Set the tool on its side to expose the Bolts(l).

5. Loosen Bolts (l) and remove Drive Guide(H) to

expose the jammed fastener.

6. Remove jammed fastener, using plier or a

screwdriver if required.

7. Replace the Drive Guide(H) and Bolts(l).

8. Reconnect tool to the air source, then reload

the tool With fasteners.

9. Press the Drive Guide (H) against a piece of

wood, and test fire the fasteners several times

to check for proper operation. If the tool is

properly firing, you may continue using the tool.

If the tool fails to perform properly, immediately

discontinue use and have the tool repaired by a

qualified service technician.

Bolts(l)

Drive Guide(H)

NL.ounÄ

Drive Guide(H)

MODEL: SFL618

LUBRICATION

Frequent, but not excessive, lubrication is required

for best performance. The oil added through the air

line helps to prevent rust and lubricate the intemal

parts of the nailer. Do not use detergent oil or

additives as these lubricants will cause accelerated

wear to the seals and bumpers in the tool, resulting

in poor tool performance and frequent tool

maintenance.

Disconnect the air supply from the tool to add

lubricant.

2. Turn the tool so the air inlet is facing up. Place

2—3drops of pneumatic fastening tool oil into air

inlet. Do not use detergent oils, oil additives, or

air—tool oils as these lubricants will cause

accelerated wear to the seals and bumpers in

the tool, resulting in poor tool performance and

frequent tool maintenance.

3. After adding oil, run tool briefly.

excess oil from the cap exhaust.

A WARNING:

Make sure there is no fastener in the

Wipe off any

specified

CAUTION:

Lubricate tool

lubricants.

CAUTION:

only with

magazine before clearing a jam.

A WARNING:

Disconnect the tool from the air source

whenever clearing a jam.

After

disconnecting the tool from the air

compressor, there should still be enough

air pressure to fire the tool. After the air

hose is disconnected, always fire the tool

into scrap wood repeatedly to make sure

all of the compressed air is expended.

MAINTENANCE

A WARNING:

Any time inspection, maintenance, and

cleaning are done:

Disconnect the tool from the air

source.

Empty the magazine completely.

ANTI-DUST

Each tool is packed with an anti-dust cap on the air

connector, check it after unpacking.

Keep the anti-dust cap to cover the air connector

when the tool is not in use to prevent the dust.

The work surface can become damaged by

excessive lubrication. Proper lubrication is

the owner' s responsibility. Failure to

lubricate the tool properly will

dramatically shorten the life of the tool

and void your warranty.

CLEANING

Avoid using solvents when cleaning plastic pans.

Most plastics are susceptible to damage from

various types of commercial solvents and maybe

damaged by their use. Use clean cloths to remove

dirt, dust, oil, grease, etc.

A WARNING:

Do not at any time let brake fluids,

gasoline, petroleum-based products,

penetration oils, etc. come in contact with

plastic parts. Chemicals can damage,

weaken or destroy plastic which may

result in serious personal injury.

12

HTTP://WWW. NUMAXTOOLS. COM

1-888-669-5672

HTTP://WWW. NUMAXTOOLS. COM

1-888-669-5672

13

Loading...

Loading...