Items necessary for starting

Tools, accessories, etc.The following items are necessary

for operating the engine.

BEFORE STARTING

Battery leads

Electric starter and starter battery

Hexagon starting shaft

Glowplug battery

Fuel

Fuel Filter

Fuel Pump

Silicone Fuel Line

TOOLS

Screwdriver

Phillips Screwdriver

Socket Drivers

Hex Drivers

End Wrenches

Needle Nose Pliers

0.S. SPEED Plug Wrench (optional extra)

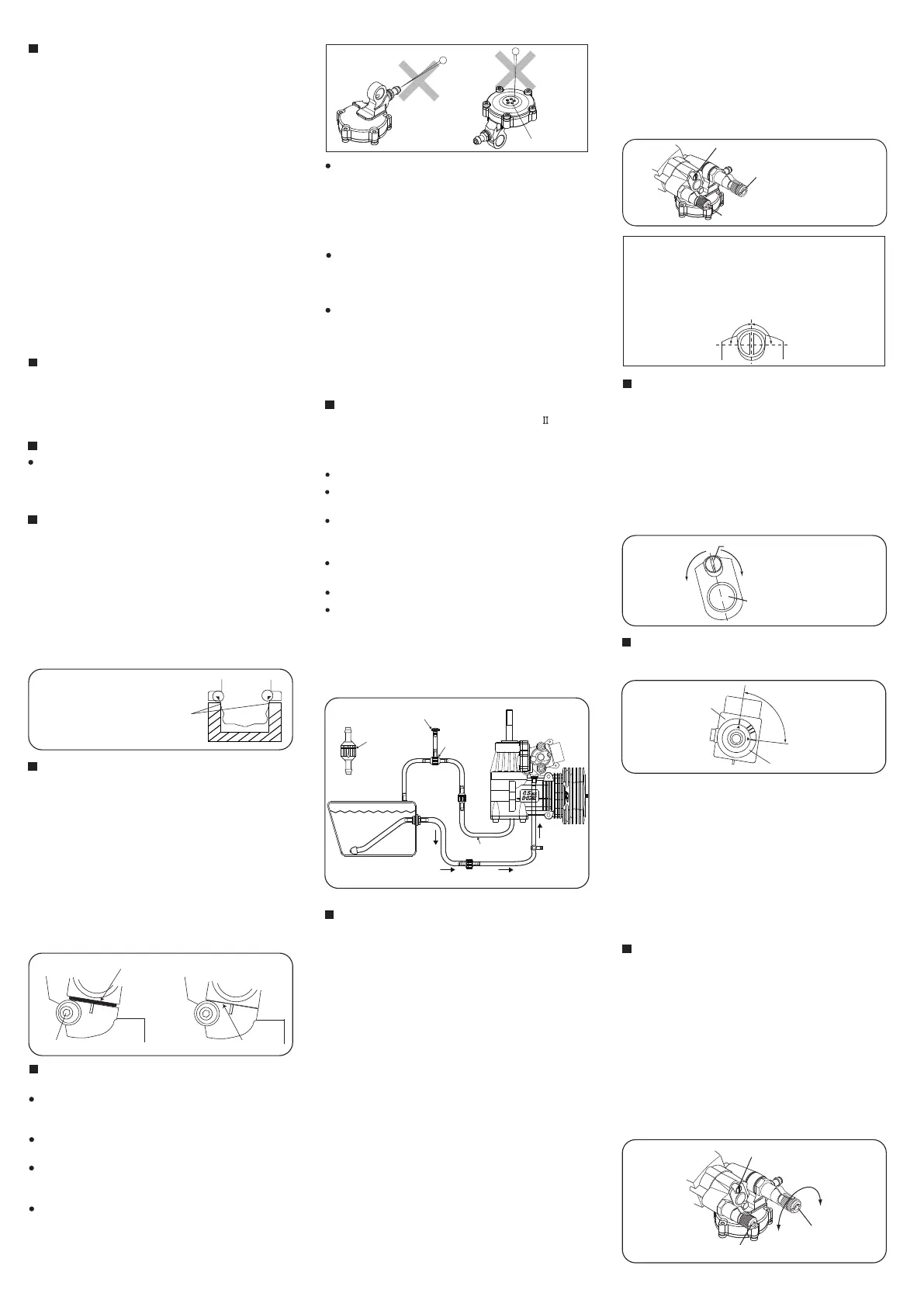

INSTALLATION OF THE ENGINE

Make sure that only the under-surfaces

of the engine’s mounting lugs are in

contact with the engine mount.

INSTALLING THE GLOWPLUG

Install washer on glowplug and insert carefully into

Heatsink-head, making sure that it is not cross-threaded

before tightening firmly.

INSTALLATION OF THE CARBURETOR

INSTALLATION OF THE STANDARD ACCESSORIES

CARBURETOR CONTROLS

O.S. Super Filter (Fuel Can Filter)

The under-surfaces of all O.S. engine beam mounting

lugs are precision machined flat and exactyly parallel

to the engine's horizontal axis. It is essential that the

engine mounts in the model are also accurately made

and aligned. If they are not, they will cause stress and

distortion within the engine itself, probably resulting in

loss of performance and internal damage.

The recommended screws for securing the engine to

the engine mounts in the model are 3mm or 4-40 steel

Allen type. It is also advisable to use lock washers or

LOCTITE to prevent nuts from loosening.

Select, by practical tests, the most suitable fuel from

among the best quality fuels available in your country

for helicopter use. For the best throttle response, a fuel

containing 10% to 30% nitromethane is preferable.

Lubricants may be either castor-oil or a suitable

synthetic oil (or. a blend of both) provided that they are

always of top quality. For consistent performance and

long engine life, it is essential to use fuel containing AT

LEAST 18% lubricant by volume. Some fuels

containing coloring additives tend to deterriorate and

may adversely affect running qualities. If in doubt

compare to a fuel known to be good.

1.

2.

Retainer screw

Carburetor Rubber Gasket

0.2mm gap

Insert the carburetor rubber gasket on the carburetor

body securely.

Then, insert the carburetor in the crankcase.

Rotate the retainer screw gently until it stops, then

tighten a further 90-120 degrees.

Do not over-tighten the screw as this will damage the

Carburetor Body.

3.

Loosen carburetor retainer screw slightly.

As delivered, the engine has its carburetor lightly

fitted into its intake boss. Secure it as follows.

CARE OF REGURETOR

NEVER disassemble the pressure regulator.

Their original performance may not be restored after

reassembly.

NEVER insert anything into the inlet nipple in an

attempt to clear a suspected obstruction.

DO NOT allow foreign matter to enter the fuel

system. Dirt inside the regulator, no matter how

small, may obstruct the flow of fuel and prevent a

from working properly.

DO NOT block the five holes on the top of the

regulator, or the regulator may not work properly.

Do not insert a needle or anything into these holes.

ABOUT THE REGURETOR

Five holes

ALWAYS use fuel filters.

Keep the fuel tank scrupulously clean and filter all

fuel as it enters the tank (e.g.via an O.S.'Super-Filter'

Code No.72403050) and use a good quality in-line

filter between the tank and regulator. Remember to

inspect filter screens at regular intervals and rinse

clean as necessary.

DO NOT clean the regulator with organic solvent

such as kerosene, light machine oil, gasoline,

thinner or crc as the silicone rubber parts inside will

deteriorate. Be sure to use methanol or fuel.

DO NOT allow fuel to remain in the regulator.

After finishing the day's flight session, be sure to run

out the fuel in the regulator. Stop the fuel flow to the

regulator with a stopper and run the engine at idle to

use up the fuel in the regulator. After stopping the

engine, rotate the engine by electric starter to

eliminate fuel inside the engine.

It is suggested to use the O.S. Power Boost 55 silencer

which is developed to best Match the 55HZ-R.

Carry out plumbing referring to the instructions

supplied with the silencer.

ABOUT THE SILENCER AND PLUMBING

Carry out plumbing referring to a sketch.

Connect silicone tubing cut into approx. 10cm to the

nipple on the cover plate.

Then, connect the check valve supplied with the

engine as sketched (Be aware of the direction.) It is

suggested to install a stopper as shown in the sketch.

When refueling, remove this stopper to release

pressure in the fuel tank.

Connect the fuel line to the nipple on the regulator.

Be sure to equip a commercially available in-line filter

to avoid dust entering the regulator.

Note:

Since the muffler pressurized fuel feed is not used

with this engine, plug the nipple on the muffler or

replace it with a bolt.

Fuel tank

Fuel Stopper

(commercially

available)

Fuel Filter

(commercially available)

Check valve

Check valve

Fuel Stopper

(commercially available)

T Nipple

Remove when refuelling

(commercially

available)

Be aware of

direction

Grooved part should

face the fuel tank.

Silicone tubing

approx.10cm

(commercially

available)

With a fixed-wing model, power failure is rarely a

serious threat to the safety of the aircraft since it can

usually glide down to a safe landing. In a helicopter,

on the other hand, it is vitally imporant that the engine

keeps running and that there is a quick and reliable

response to the throttle in order to ensure safe ascent

and descent of the model.

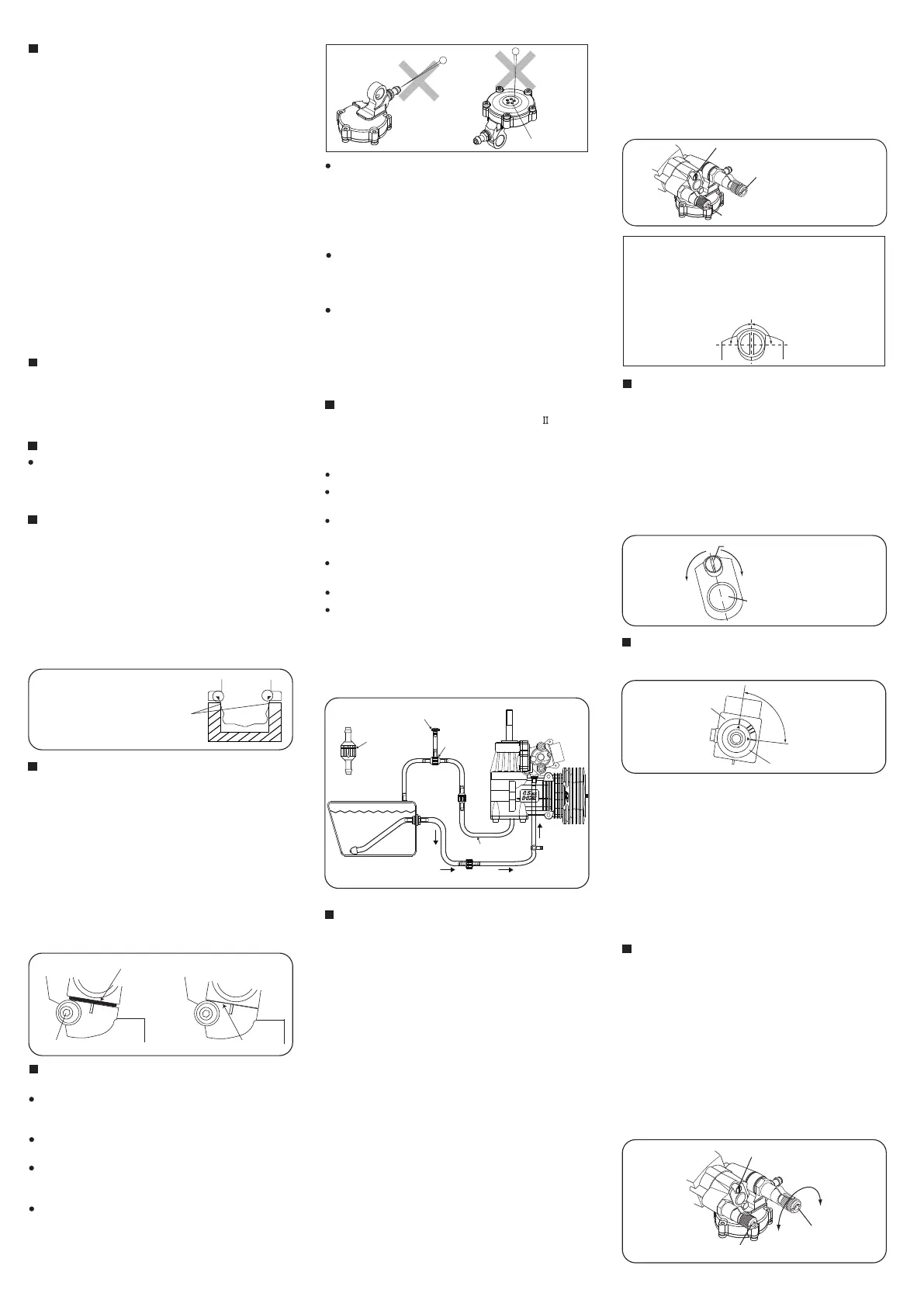

The High-Speed (Main) Needle Valve

When set to produce maximum power at full throttle,

this establishes the basic fuel/air mixture strength.

This is then maintained by the carburetor's

automatic mixture control system to cover the

engine's requirements at reduced throttle settings.

The Idle Mixture Control Screw

This provides the means of manually adjusting the

mixture control valve. By setting the Mixture Control

Screw for the best idling performance, the mixture

control valve automatically ensures that fuel is

accurately metered to maintain the correct mixture

strength as the throttle is opened.

Three adjustable mixture controls are incorporated in the

Type 40L-R. They are as follows.

A

B

The Medium Speed Needle Valve

This is an extra control that can be brought into

play, if necessary, after adjusting A and B above. It

provides the means of fine-tuning mixture strength

over that all-important part of a helicopter's throttle

range where the model is flying in, or near, the

hovering mode.

C

Idle MIxture Control Screw

High Speed Needle Valve

(Main Needle)

Medium Speed Needle Valve

NOTE

90 degrees

90 degrees

As the idle mixture control screw is installed with

LOCTITE, it may initialy feel stiff, and it is suggested to

use a slightly oversized screwdriver. The screw can be

turned only 90 degrees either way. Do not force to turn

further, or it may break or cause trouble.

BASIC POSITION OF MIXTURE CONTROL SCREW

(Mixture Control Valve)

Rich

Mixture Control Valve

MIxture Control Screw

Lean

As delivered, the Mixture Control Screw is positioned at

approximately the center as shown in the sketch. Mixture

gets lean when the Mixture Control Screw is turned right,

while mixture gets rich when the Mixture Control Screw is

turned left.With a model helicopter, adjustments vary with

combined various factors such as climatic conditions,

fuel, muffler, main rotor, weight of the model, gear ratio,

etc. Therefore the Mixture Control Screw position varies

with each model and set- up, and it is normal if the Mixture

Control Screw position is off the center.

89 degrees

When the triangle mark on the carburetor rotor meets

the far right mark, the throttle is fully closed. When the

triangle mark meets the top mark, the throttle is fully

open. The range is 89 degrees. You may use the other

three marks as the reference marking of throttle

opening to your preference when hovering.

WARNING!

Never try to check the triangle mark position while

the engine is running and rotor is rotating, or you

may be hit by rotating rotor which results in serious

injury. Stop the engine and rotor before checking

the triangle mark position.

Carburetor Rotor

Carburetor Body

Fully closed

position

Fully opened position

As shown in the sketch, the carburetor has graduation

marks.

GRADUATIONS ON THE CARBURETOR BODY

Note: In case it is hard to insert the carburetor in

the crankcase. Do not force it, or damage to the

crankcase can occur.

(optional extra)

Be sure to use an electric starter to start the engine.

Fill the fuel tank with fuel. When filled, prevent the

fuel from flowing into the carburetor with a

commercially available fuel stopper, etc.

Release the stopper before starting the engine.

1.

2.

Starting procedure is as follows:

Make sure that plug element glows red, and install

the plug in the cylinder head.

STARTING

Open

1.

Opening and closing of the Needle-Valve

Turn the needle clockwise to close the needle-valve,

and turn the needle counter-clockwise to open the

needle-valve as shown in the sketch.

Close

High Speed

needle-valve

Idle Mixture Control Screw

Medium Speed needle-valve

Loading...

Loading...