KM1 KM2

S2

S3

S2

S1

M1

KM1

KM2

0V

E1

0VDC (Brown)

Standby input (Violet)

Zone Select 1 (Orange/White)

Zone Select 2 (Orange/Black)

Zone Select 3 (Gray)

Start (Black)

Auxiliary output(Blue)

Warning output (Red/Black)

EDM (Brown/White)

Safety output B (Yellow)

Safety output A

(Red)

* 2

*3

*3

* 1

+24V

Basic connection (with single OS32C unit)

Category 3, Performance Level d(ISO13849-1)

S1 : Start Input

S2 : Zone Select Switch

S3 : Standby Switch

KM1, KM2: Forced guided relay (G7SA)

or magnetic contactor

M1 : 3-Phase Motor

E1 : 24 VDC Power

Functional Earth (Green)

24VDC (White)

OS32C Configuration

- Start/Restart Interlock

Zone Select 4 (Pink)

Zone Select 5 (White/Black)

S2

*3

S2

*3

S2

*3

*3

*3

*3

Zone Select 6 (Tan)

Zone Select 7 (Orange)

Zone Select 8 (Blue/White)

S2

S2

S2

*1. If the External Device Monitoring is not used, connect brown/white wires to 0V,

and then disable the External Device Monitoring with the configuration software.

*2.

The Start Input must be a Normally Closed switch.

*3. For zone select switch setting, see Zone Set Input Selection. When using only one zone,

no connection is needed for the zone select inputs.

KM1

KM2

PE

- External Device Monitoring

Enabled

Wiring Connections

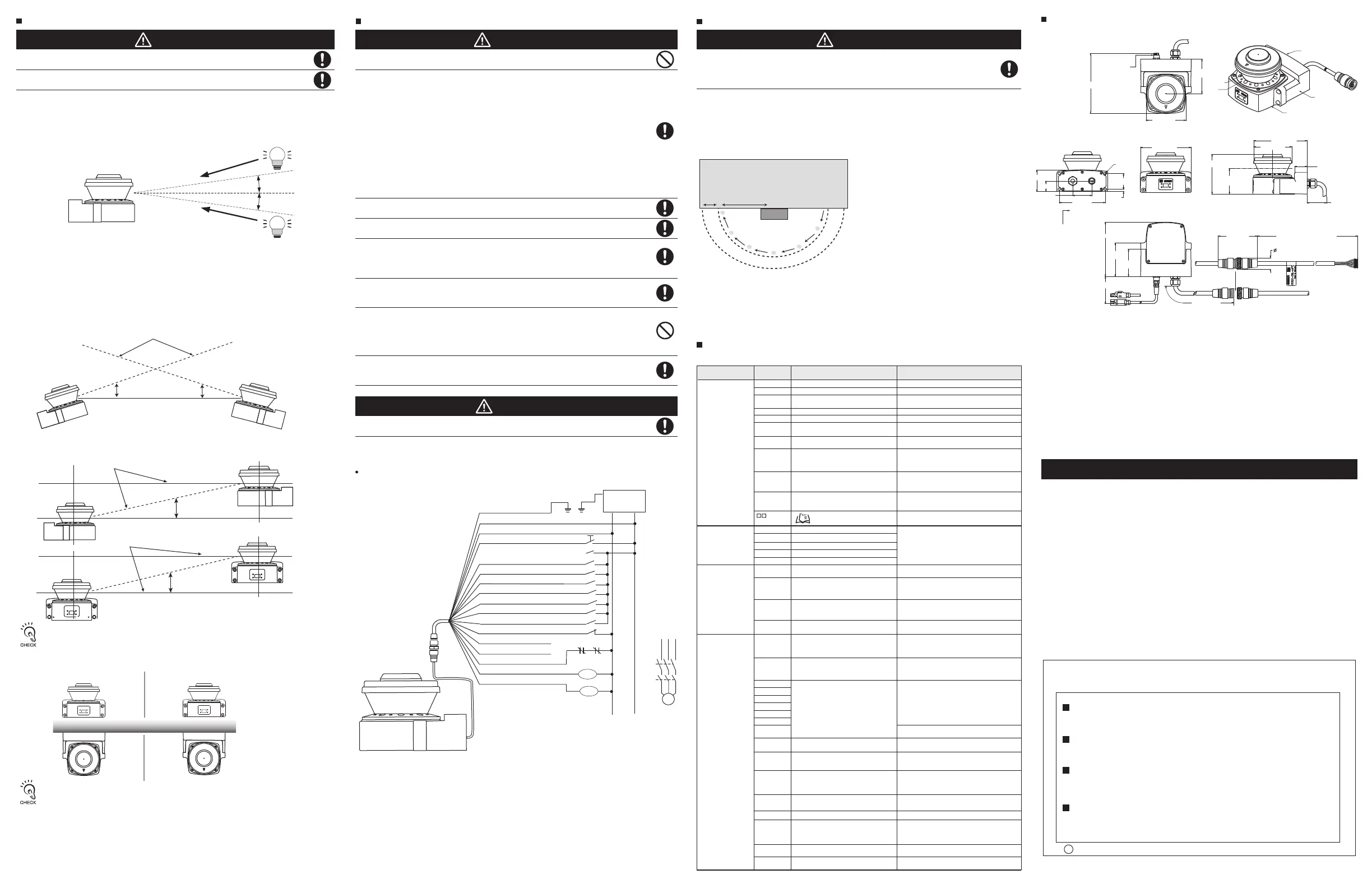

Testing a Horizontal Safety Zone

Top view

Guarded machine

OS32C

Safety Zone

STOP START

Warning Zone

1 m 2 m

If the OS32C is operating in automatic start mode, make sure that the machine

stops and not restart when the test object is in the safety zone. Check its operation

by approach of a test object into a safety zone. It is recommended that this test be

performed after a shift change or 24 hours of operation.

To test the OS32C’s detection capability, guide the test object along the perimeter of the safety detection

zone as shown in the figure below. The hazardous motion of the guarded equipment must stop immediately

(within the pre- determined accepted stop times). While in Automatic Start Mode, the OS32C MUST

remain in the machine stop state throughout the entire test.

To test the OS32C, use a test object with a diameter appropriate for the selected resolution.

(A test object does not come with the OS32C).

Note:

In this example, a semicircle is configured as 2m of

safety zone and 3m of warning zone.

Verify that all indicators and displays are operating properly and correspond to their defined functions of the

OS32C. Inspect the OS32C housing and the exit window for signs of damage or manipulation.

If the OS32C is used in a stationary guarding application, ensure that the safety zone(s) are clearly marked

on the floor. For mobile applications, make sure that the vehicle stops moving within the limits set in the initial

configuration.

If the OS32C fails any of these tests, lock out the guarded equipment and contact the factory supervisor

immediately.

Testing the Safety Area

The OS32C has the status/diagnostic display on the front, which indicates configuration/error status of

the OS32C.

OS32C Status Check

Status Description

Corrective Action

-

88

- -

-

-

-

Normal Operation

Power up indication

Normal operation (guarded machine stop)

Diagnostic

Code

- - blinking at

1 Hz

01

Standby mode (guarded machine stop)

Interlock state (waiting for start input)

Configuration mode (guarded machine stop)

02

80

Window contamination indication

(guarded machine stop)

70

Incorrect number of active zone inputs

(guarded machine stop)

The window is dirty or scratched, clean or

replace as necessary

83

Window condensation indication

(guarded machine stop)

Condensation is detected in the window, wait

for unit to warm up

84

Blinded beams indication (guarded

machine stop)

Check for mutual interference with another scanner

(see mounting considerations on the user manual),

nearby retro-reflectors or strong interfering light

sources.

71

Invalid or undefined zone input

combination but correct number of active

zone inputs (guarded machine stop)

Safety output fault

Safety output fault

Safety output A is short-circuited to 24V

33

32

Safety output B is short-circuited to 24V

34

Safety output A is short-circuited to 0V

35

Safety output B is short-circuited to 0V

30

Check output connection and wiring

40

EDM (external device monitoring)

fault

Check output external device monitoring

connection and wiring.

Check the NC-contact status of the external

device is changing state before the OSSDs

turning ON.

Check the NC-contact status of the external

device is changing state after the OSSDs

turning ON.

Check the OS32Cs output configuration,

connections and wiring.

Check environment for excessive vibration, shock or

electrical noise; check that the window assembly is

undamaged and securely attached. Or consult factory.

Check for mutual interference with another scanner (see

mounting considerations on the user manual), nearby

retro reflectors (<1m) or strong interfering light sources.

Check the environment for electrical noise

sources or interfering light sources. Or consult

factory.

Check environment for excessive vibration or

shock.

Double check current configuration or reset the

scanner back to manufacture default configuration.

Check zone set select input wiring and zone

configuration selection.

Scanner chassis should be grounded to 0 VDC .

The scanner internal temperature exceeds the

operating limit. Add more ventilation.

41

42

43

External device monitoring fault

before OSSD turning ON

External device monitoring fault after

OSSD turning ON

External device monitoring fault during

OS32C power on

50

51

52

53

54

56

57

58

59

60

Other fault

General fault - caused by internal

problem or extreme environmental

condition

Mutual interference

General fault - caused by internal

problem or extreme environmental

condition

Invalid configuration in unit

72

73

74

75

90

Incorrect number of active zone inputs

(hard fault code after diagnostic code 70

above persists for more than 10 minutes)

Invalid or undefined zone set select input

combination, but correct number of active zone

set select inputs.(hard fault code after diagnostic

code 71 persists for more than 10 minutes)

Standby input or zone inputs voltage

too high

Scanner chassis connected to power (24 VDC).

Cycle power on unit and allow to run with diagnostic

code 83, internal generated heat will reduce

condensation.

(if possible reduce moisture in the environment)

81

Window condensation (fault code after

diagnostic code 83 persists for more

than 30 minutes)

Internal temperature fault

External device

monitoring fault

Refer to Status/Diagnostic Display

Indication of the OS32C user's manual

82

Window not detected or entire dust

detection surface is dirty or blocked.

Check that the window is properly mounted

and clean the dust detection surface.

Check zone set select input wiring, zone

configuration selection, zone set select input

switching time and zone delay configuration

Check zone set select input wiring, zone

configuration selection, zone set select input

switching time and zone delay configuration

Check zone set select input wiring and zone

configuration selection.

Check zone set select inputs or standby input

wired at more than system power (24 VDC).

Do not connect the OS32C to a power supply with more than 24VDC + 25% /

-30%. Do not supply AC power to the OS32C, this may result in electrical shock.

For the OS32C to meet IEC 61496-1 and UL 508, its DC power supply unit must

satisfy all of the following conditions:

• Within rated line voltage (24 VDC +25% / -30%)

• Complying with EMC directives (industrial environments)

• Double-insulation or reinforced insulation between primary and secondary

circuits

• Automatic return for overcurrent protection

• Output retention time of 20 ms or longer

• Satisfying output characteristics requirements of Class 2 circuit or limited

voltage/current circuit defined in UL508.

• Power supply complying with regulations and standards of EMC and safety

country or a region where OS32C is used. (Example of electrical equipment

in EU, a power supply must comply with EMC directives and the Low Voltage

Directive)

To prevent electrical shock, use double-insulation or reinforced insulation from

hazardous voltage (such as 230 VAC).

Cable extensions must be within the specified lengths, otherwise it may result in a

failure of the safety functions.

To use this product for a category 3 safety system, both safety outputs must be

connected to the safety system. Configuring a safety system with only one safety

output may result in serious injuries due to output circuit fault and a failure of the

machine to stop.

Protection of Cable at Installation:

Care should be taken when installing the OS32C cable. The cable must be

properly routed and secured to ensure that damage does not occur.

Functional Earth:

The OS32C system requires a functional earth connection.

Do not connect Functional Earth to a positive ground system. If it is connected to

positive ground, the guarded machine to be controlled may NOT stop, resulting in

severe operator injury.

Signal Connector Isolation:

The connectors used during installation must provide sufficient signal separation

in order to prevent a short circuit condition of the input power and system signals.

OSTI P/N 99863-0020 Rev.H

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM

AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT

THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR

THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

When wiring the OS32C to external devices, make sure to follow the color and

coding schemes per EN 60204-1.

Operation of the OS32C may be affected by light in the environment, such as

incandescent light, strobe light and light from a photosensor using infrared light.

Operation of the OS32C may be affected by substances in the environment, such

as fog, smoke, steam and other small particles.

The following considerations should be taken into account when determining the mounting location for

the OS32C. It is possible for ambient light to interfere with normal operation of the OS32C.

Ambient light interference DOES NOT lead to a loss of safety, it may, however, cause false nuisance

stops of the guarded equipment.

Some installations may require that the OS32C be mounted in direct exposure to ambient light. In these

situations you must assure that the separation between the scan plane of the OS32C and the light source

be greater than +/-5°.

Mounting Considerations

Configuring Multiple OS32C Scanners

5° or more

5° or more

Offset Scanning Level by Tilting

Offset Parallel Scanning Levels by Different Installation Height

Separation using a screen

Detection Plane

5°or more

5°or more

Detection Plane

5°or more

Detection Plane

5°or more

Top View

Front View

Screen

The possibility exists that two OS32C may interfere with each other. To avoid this when using

multiple OS32C in the same location, please review the following mounting recommendations.

• Adjust the scanners to offset the scanning plane by tilting the OS32Cs.

• Adjust the scanners to offset the scanning plane by mounting the OS32Cs at different heights.

• Adjust the scanners to different scanning planes and additional sampling scans (response

time) on the OS32Cs.

• Install a barrier to block the direct path of possible signal crossing.

When installing the OS32Cs side by side, it is more effective to set their mounting heights

differently. When adjusting the OS32C tilted, it may be more effective to adjust the OS32C

downward depending on the condition of the outside light source (natural light or halogen light).

Use of a screen may increase the effect of reflection depending on its material. Select one with

matte black finish that is resistant to reflection.

Model (OS32C-BP) shown

158.3 [6.24]

Ethernet connector

with M12 cap plug

(cable not shown)

104.3 [4.11]

Top view

90.4 [3.56]

Window

Dust

Detection

Ethernet cable

not shown

I/O cable

I/O block

Sensor head

Isometric view

140.4 [5.53]

100.0 [3.94]

32.8 [1.29]

50.9 [2.01]

Side view

104.5 [4.12]

67.0 [2.64]

Scan plane

133.0 [5.24]

M5x0.8 (x4)

41.4 [1.63]

Mtg holes

57.0 [2.25]

27.7 [1.09]

50.0 [1.97]

6.0 [0.24]

121.0 [4.77]

Mtg holes

Back view

142.7 [5.62]

Front view

Ethernet connector with M12

cap plug (cable not shown)

88.1[3.47]

71.5 [2.82]

71.3 [2.81] (min)

Ethernet

cable

Bottom view

I/O cable

270 (10.63)

Back plate

I/O cable assy

for OS32C-BP

3.0, 10.0, 20.0 or 30.0 meters

30.0 [1.18]OD

Controller cable assy

OS32C Dimensions

102.9 [4.05]

DIMENSIONS: mm [inches]

CAUTION

CAUTION

WARNING

WARNING

Suitability for Use

s

Oct, 2014

D

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON EUROPE B.V.(Representative and Importer in EU)

Wegalaan 67-69, NL-2132 JD Hoofddorp

THE NETHERLANDS

Tel: (31) 2356-81-300/Fax: (31) 2356-81-388

Shiokoji Horikawa, Shimogyo-ku, KYOTO, 600-8530 JAPAN

OMRON Corporation Industrial Automation Company(Manufacturer)

Contact: www.ia.omron.com

Regional Headquarters

Loading...

Loading...