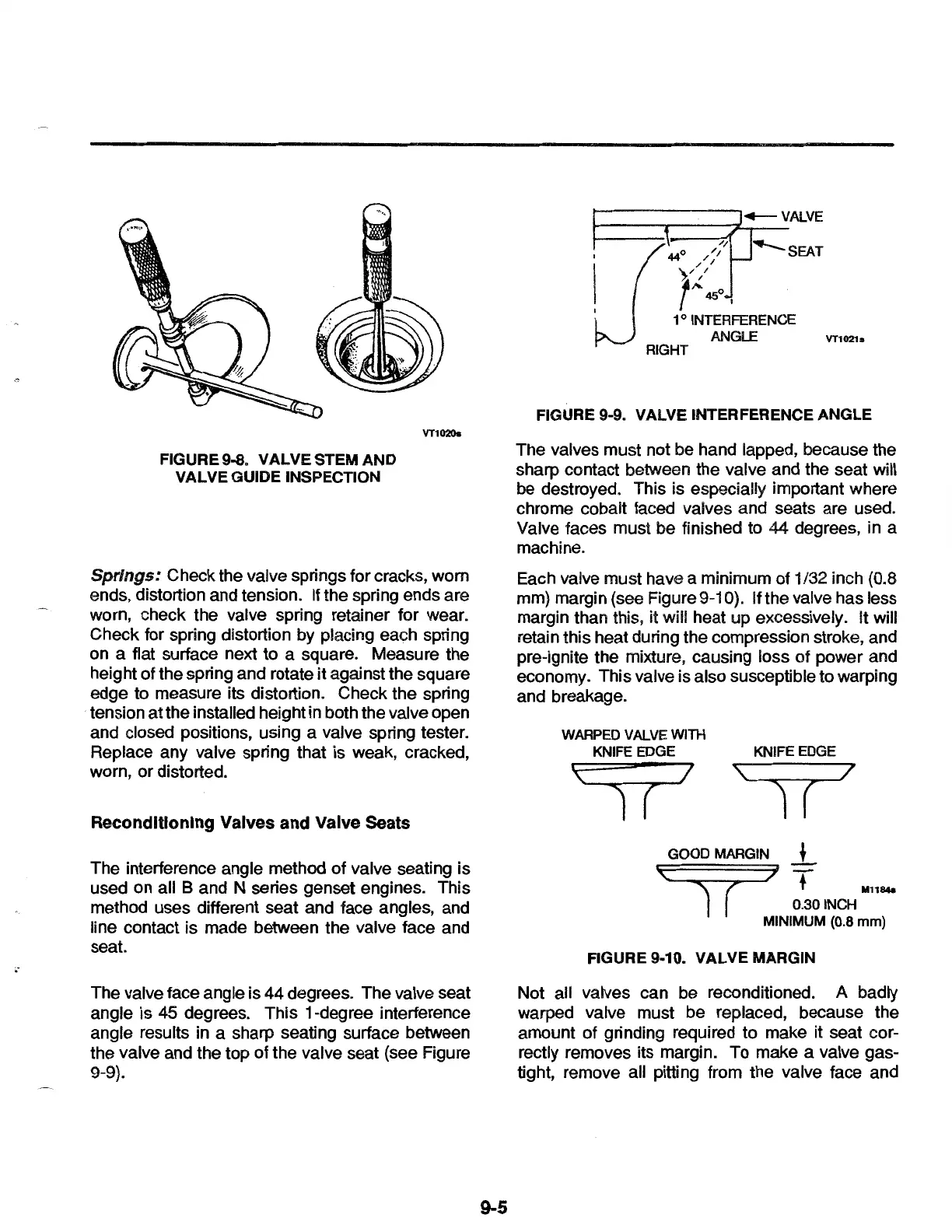

FIGURE 9-8. VALVE STEM AND

VALVE GUIDE INSPECTION

VT1020s

Springs: Check the valve springs for cracks, worn

ends, distortion and tension.

If

the spring ends are

worn, check the valve spring retainer for wear.

Check for spring distortion by placing each spring

on

a flat surface next to a square. Measure the

height of the spring and rotate it against the square

edge to measure its distortion. Check the spring

tension at the installed height in both the valve open

and closed positions, using a valve spring tester.

Replace any valve spring that is weak, cracked,

worn, or distorted.

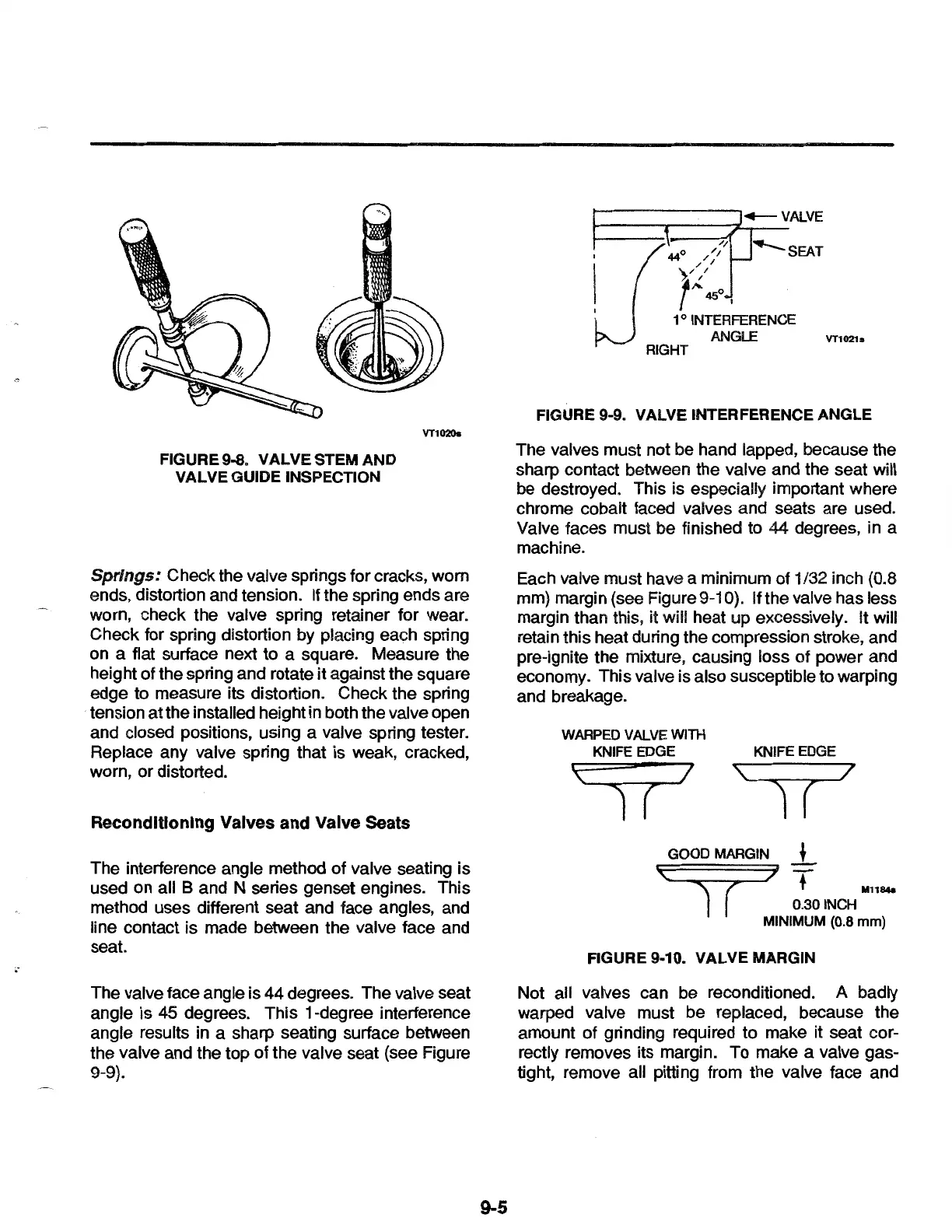

Reconditioning Valves and Valve Seats

The interference angle method of valve seating is

used on all B and N series genset engines. This

method uses different seat and face angles, and

line contact is made between the valve face and

seat.

The valve face angle is

44

degrees. The valve seat

angle is 45 degrees. This 1-degree interference

angle results in a sharp seating surface between

the valve and the top of the valve seat (see Figure

9-9).

9-5

VT1021s

FIGURE 9-9. VALVE INTERFERENCE ANGLE

The valves must not be hand lapped, because the

sharp contact between the valve and the seat will

be destroyed. This is especially important where

chrome cobalt faced valves and seats are used.

Valve faces must be finished to 44 degrees, in a

machine.

Each valve must have a minimum of 1/32 inch (0.8

mm) margin (see Figure

9-1

0). If the valve has less

margin than this,

it will heat up excessively. It will

retain this heat during the compression stroke, and

pre-ignite the mixture, causing loss of power and

economy. This valve is also susceptible to warping

and breakage.

KNIFE EDGE

l (

\ 7

1 (

GOOD MARGIN

_!_

\ )

T

I(

111184a

0.301NCH

MINIMUM (0.8

mm)

FIGURE 9-10. VALVE MARGIN

Not all valves can be reconditioned. A badly

warped valve must be replaced, because the

amount of grinding required to make it seat cor-

rectly removes its margin. To make a valve gas-

tight, remove all pitting from the valve face and

Loading...

Loading...