Bleeding

Fuel

System

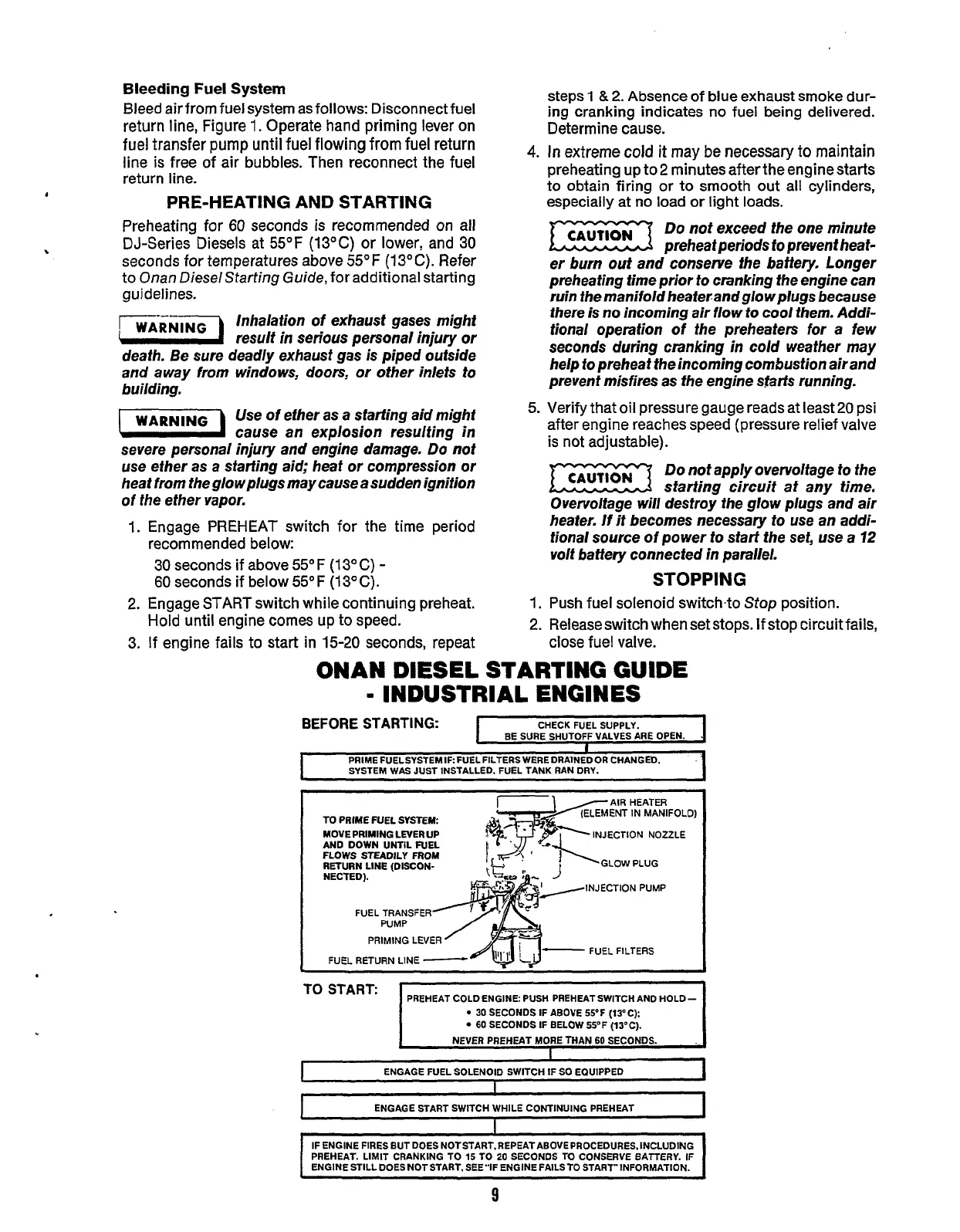

Bleed airfrom fuel system asfollows: Disconnectfuel

return

line,

Figure

1.

Operate hand priming lever on

fuel transfer pump until fuel flowing from fuel return

line is free of air bubbles. Then reconnect the fuel

return line.

Preheating for

60

seconds

is

recommended on all

DJ-Series Diesels at 55°F

(13°C)

or lower, and

30

seconds

for

temperatures above

55°F

(13OC).

Refer

to

Onan

Diesel

Starting

Guide,

for additional starting

guidelines.

Inhalation of exhaust gases might

result in serious personal injury or

death. Be sure deadly exhaust gas

is

piped outside

and away from windows, doors, or other inlets to

building.

Use of ether as a sfarfing aid might

i

cause an explosion resulting in

severe personal injury and engine damage.

Do

not

use ether as a starting aid; heat or compression or

heat

from

the glowplugs may cause asudden ignition

of the ether vapor.

1.

Engage PREHEAT switch for the time period

4

PRE-HEATING AND STARTING

b

p

WnRNlNGI

recommended below:

30

seconds if above

55"

F

(13" C)

-

60

seconds if below

55°F

(13°C).

2.

Engage START switch while continuing preheat.

3.

If engine fails to start in

15-20

seconds, repeat

Hold

until engine comes up to speed.

To

START

4.

5.

1,

n

PREHEAT COLD ENGINE PUSH PREHEAT SWITCH AND HOLD-

*

30

SECONDS IF ABOVE

55OF

(13°C);

60

SECONDS

IF

BELOW

55OF

(13'C).

NEVER PREHEAT MORE THAN

60

SECONDS.

steps

1

&

2.

Absence

of

blue

exhaust

smoke

dur-

ing cranking indicates

no

fuel being delivered.

Determine cause.

In

extreme cold

it

may

be necessary to maintain

preheating up to

2

minutes after the engine starts

to obtain firing

or

to smooth

out

all cylinders,

especially at no load

or

light loads.

Do

not

exceed the one minute

preheat periods to prevent heat-

er burn

out

and conserve the battery. Longer

preheating time prior

to

cranking the engine can

ruin the manifold heaterandglowplugs because

fhere

is

no

incoming air flow

io

cool them. Addi-

tional operation

of

the preheaters for a few

seconds during cranking in cold weather may

help

to

preheat the incoming combustion air and

prevent misfires as the engine

starts

running.

Verify that oil pressure gauge reads at least

20

psi

after engine reaches speed (pressure relief valve

is

not adjustable).

Do

not

apply overvoltage

to

the

starting circuit at any

time.

Overvoltage will destroy the glow plugs and air

heater.

If

jt becomes necessary

to

use an addi-

tional source of power

to

start the set, use a

72

volt baffery connected in parallel.

STOPPING

Push fuel solenoid switch40

Stop

position.

L.

Release switch when set stops.

If

stop circuit fails,

close fuel valve.

ONAN DIESEL STARTING GUIDE

-

INDUSTRIAL ENGINES

BEFORE

STARTING: CHECK FUEL SUPPLY.

BE SURE SHUTOFF VALVES ARE OPEN.

I

1

PRIME FUELSYSTEMIFFUEL FILTERS WEREDRAlNED

OR

CHANGED.

SYSTEM WAS JUST INSTALLED. FUEL TANK RAN

DRY.

1

1

i

1

-AIR HEATER

1

ELEMENT IN MANIFOL

TO PRIME FUEL

SYSTEM

MOVEPRIMING LEVERUP JECTION NOZZLE

AND

DOWN UNTIL FUEL

FLOWS STEADILY

FROM

RETURN

LINE (DISCON- LOW PLUG

NECTED).

INJECTION PUMP

FUEL TRANSFER

PUMP

PRIMING

LEVER

-

FUEL FILTERS

FUEL RETURN LINE

-

I

~ ~~~

IF ENGINE FIRES BUT DOES NOTSTART. REPEAT ABOVE PROCEDURES, INCLUDING

PREHEAT. LIMIT CRANKING TO

15

TO

20

SECONDS TO CONSERVE BATTERY. IF

r

ENGINE STILL DOESNOTSTART. SEEYF ENGINE FAILS

TO

START" INFORMATION.

9

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...