TIMING

PSU

OR

MODEL

50

INJECTION

PUMPS

One of two methods can be used to determine the

proper timing button to time the fuel injection pump

correctly to the engine.

Method

1

Timing

by

Calculation

This procedure is used, when all dimensions are

available for replacing an old pump, before the pump

is installed. Timing by calculation requires the port

closing dimension and button thickness from the

pump being replaced.

It

also requires the port closing

dimension of the new pump. Put the dimensions in

the PORT CLOSING FORMULA, and calculate the

new button thickness. After determining the timing

button thickness, find the button code in Table

1.

If

injection pump is removed from the engine, make

sure the steel shims between pump and cylinder

block mounting remain the same. These shims main-

tain proper gear backlash.

Do

not change the pump mounting

LZx

shim’s total thickness or the proper

pump gear to camshaft gear mesh will be affected.

The shim’s thickness is established at the factory

during engine assembly and does not change unless

a new cylinder block is installed.

CAUT,ON

Port Closing Formula:

The formula for determining

the proper port closing (PC) timing button for a new

or replacement pump is as follows:

1.

Remove old pump.

2.

Determine port closing dimensions and original

button thickness from old pump.

A. Write down port closing dimension given on

old pump flange and port closing dimension

given on new pump flange. See example.

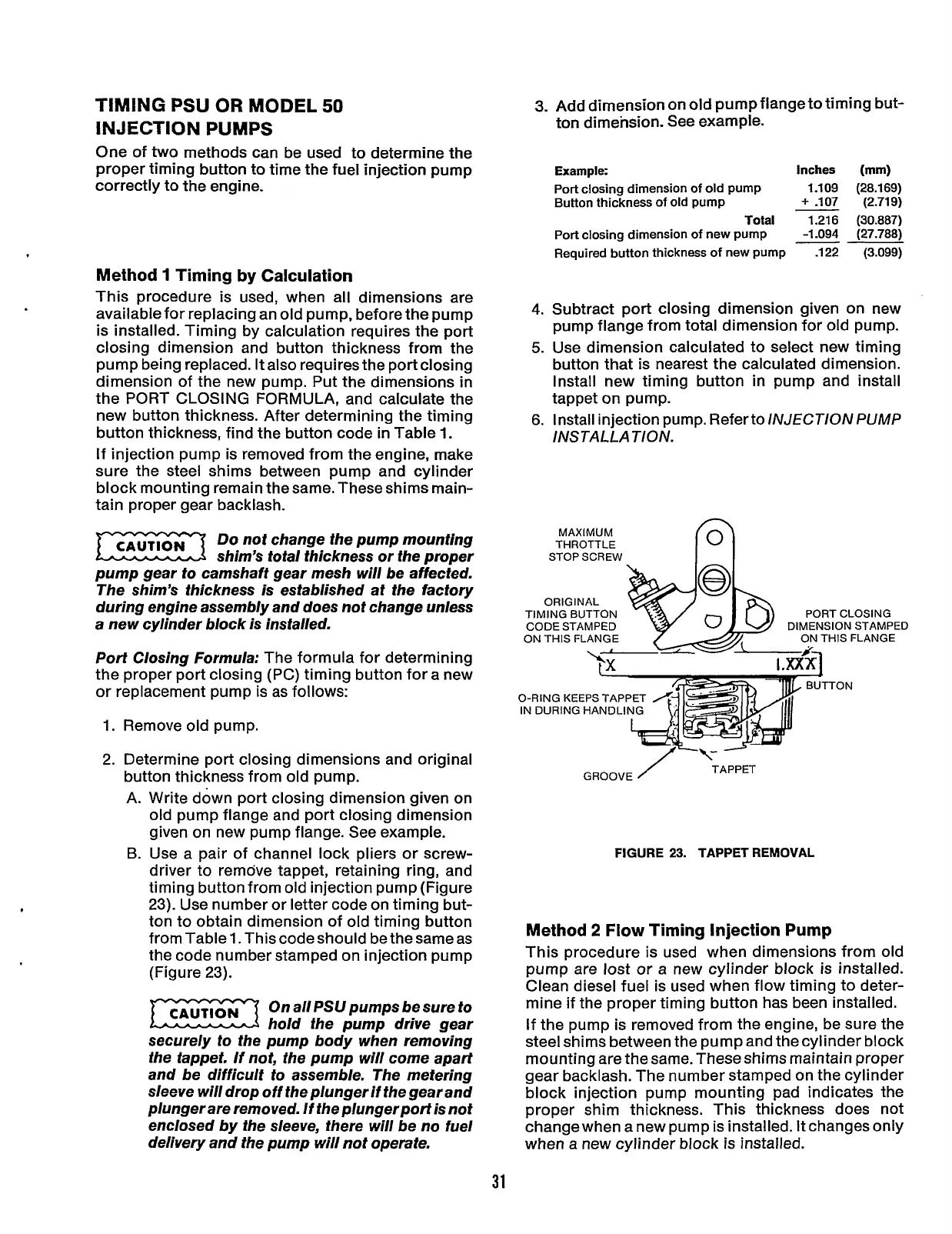

B.

Use a pair of channel lock pliers or screw-

driver to remove tappet, retaining ring, and

timing button from old injection pump (Figure

23).

Use number or letter code on timing but-

ton to obtain dimension of old timing button

from Table

1.

This code should be the same as

the code number stamped on injection pump

(Figure

23).

CAUT,ON

OnallPSUpumpsbesureto

rn

hold the pump drive gear

securely to the pump body when removing

the tappet.

If

not, the pump will come apart

and be difficult to assemble. The metering

sleeve will drop off the plunger if the gear and

plunger are removed. If the plungerport is not

enclosed by the sleeve, there will be no fuel

delivery and the pump will not operate.

3.

4.

5.

6.

Add dimension on

old

pump flange to timing but-

ton dimension. See example.

Example:

Inches

(mm)

Port

closing dimension

of

old pump 1.109 (28.169)

Button thickness

of

old

pump

+

-107 (2.719)

Total 1.216 (30.887)

Port

closing dimension

of

new pump -1.094 (27.788)

Required button thickness

of

new pump .122 (3.099)

Subtract port closing dimension given on new

pump flange from total dimension for old pump.

Use dimension calculated to select new timing

button that is nearest the calculated dimension.

Install new timing button in pump and install

tappet on pump.

Install injection pump. Refer to

lNJECT1ON

PUMP

INSTAL LA TION.

MAXIMUM

THROTTLE

STOP SCREW

II

CODE STAMPED

ON THIS FLANGE

O-RING KEEPS

IN DURING HA

----+

BUTTON

/

GROOVE

TAPPET

FIGURE

23.

TAPPET REMOVAL

Method

2

Flow

Timing Injection Pump

This procedure is used when dimensions from old

pump are lost or a new cylinder block is installed.

Clean diesel fuel is used when flow timing to deter-

mine if the proper timing button has been installed.

If the pump is removed from the engine, be sure the

steel shims between the pump and the cylinder block

mounting are the same. These shims maintain proper

gear backlash. The number stamped on the cylinder

block injection pump mounting pad indicates the

proper shim thickness. This thickness does not

change when a new pump is installed. It changes only

when a new cylinder block is installed.

31

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...