8 HOBO LCD Temp/RH User’s Manual

remote device User’s Manuals for more details). When you change the contact

settings for the HOBO LCD logger between Normally Closed and Normally Open

operation, the new configuration is retained when the batteries are changed.

Delaying the ALERT Condition

Select No Delay to immediately activate the ALERT when conditions go outside

the defined limits, or select Time Delay to avoid unwanted ALERTs due to doors

opening, defrost cycles, or similar events. Specify the delay time (up to 2 hours)

and the ALERT will wait to activate after sensing an out-of-limit condition. If the

out-of-limit measurement value comes back into the limit range before the delay

time ends, the ALERT will not be activated. If the measured value is outside the

limits before the delay time ends, that value and ALERT DELAYED will flash.

ALERT Behavior

You can select how the ALERT function behaves once a limit has been exceeded.

Choose to maintain the ALERT condition until the host has contacted the logger

(i.e, for a status, off-load, or relaunch), or until the measurements return within

limits (i.e., ALERT is activated only while the limits are exceeded).

Testing a Remote Alarm or Autodialer

The BoxCar Pro Advanced Options screen allows you to test the contact closure

and any connected remote alarm or autodialer. After connecting your remote

device and setting the preferred closure options (Normally Closed or Normally

Open), click the Set Alert button. BoxCar Pro commands the logger to activate

the ALERT and change the condition of the contact closure. Click the Reset Alert

button to deactivate the ALERT. When testing the ALERT with the AVD-45

Autodialer, it is recommended that you activate the ALERT for up to 7 minutes to

ensure that the AVD-45 Autodialer completes its dial-out sequence (see AVD-45

Autodialer User’s Manual for details).

Temperature Accuracy and Resolution

The maximum reading error for the internal and external temperature sensors is

shown in Plot B (page 13). This is a worst case error. In a typical logger,

temperature errors will be substantially lower. NIST certification of temperature

accuracy for some sensors is available from Onset.

The temperature resolution for internal and external sensors is also shown in Plot

B (page 13). Resolution is the smallest difference between adjacent temperature

steps that the logger can report.

The logger will typically experience little or no accuracy drift unless the electronic

components or temperature sensor are damaged mechanically or by exposure to

environmental factors beyond the specifications, such as high heat and humidity.

Relative Humidity Accuracy

The relative humidity sensors used in the internal sensor model and the Temp/RH

external probe are temperature compensated. The logger’s relative humidity

HOBO LCD Temp/RH User’s Manual 9

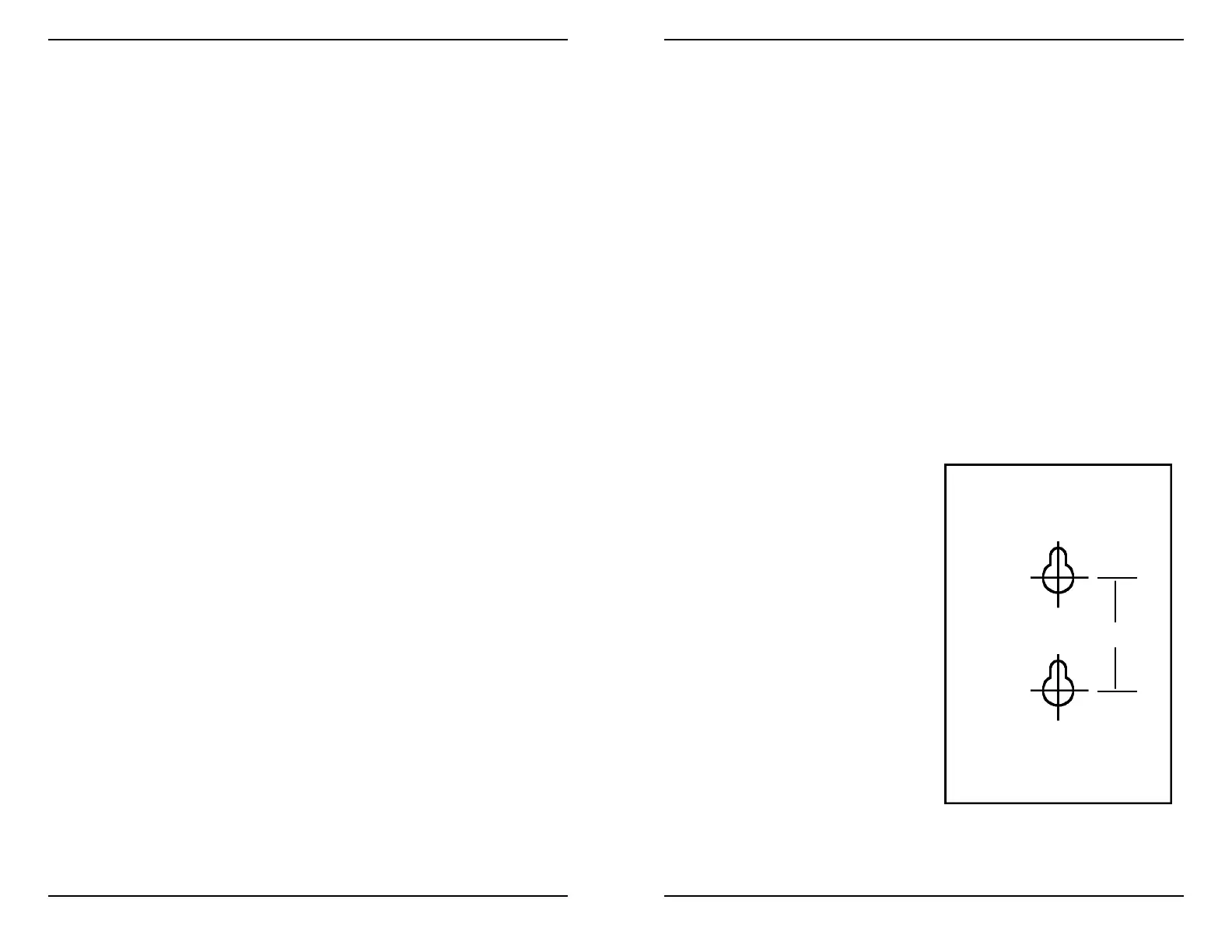

Figure 9 – Wall Mounting

Template

accuracy for the internal model is ±3% over the corresponding

temperature/humidity ranges (see specifications and Plot C, page 13). The external

probe relative humidity is ±3% over the corresponding range and ±4% in

condensing environments. The internal RH sensor has an operating RH range of 0

to 95%, and a measurement range of 15% to 95% at +25°C, and will be damaged

by condensation. Do not expose the internal RH sensor to fog, mist, or other

condensing conditions. The RH sensor used in the external probe has an operating

range of 0 to 100% in intermittent condensing environments to +30°C (+86°F); it

is recommended for only non-condensing environments above +30°C (+86°F).

Sensor measurement range is 0% to 100% between 0°C and 50°C. The external

RH sensor will not be damaged by intermittent condensation at temperatures to

+30°C (+86°F), but, if saturated, it will read approximately 100% until it dries

out. See page 11 for mounting instructions.

The internal RH sensor has an accuracy drift of less than 2% over five years in

normal operating conditions (+25°C, 50% RH, non-corrosive). The external RH

sensor may drift up to 1% per year. Accuracy is specified for the range 20% to

80%. Extended exposure to higher temperatures and/or higher relative humidity

may increase the sensor’s drift rate. You can replace the internal RH sensor

yourself or have it replaced as part of an H14-001 tune-up/calibration service

(available from Onset). The RH sensor on the external probe, however, is not

replaceable. If damaged, the whole probe must be replaced.

Wall Mounting Instructions for

Logger

1. Copy the template (Figure 9) and

tape template onto the wall in the

desired location.

2. Mark the center of holes with a

punch.

3. Screw in mounting screws, leaving a

gap between the wall and the head of

the screw of about 0.5 cm (3/16 in.).

4. Attach logger by aligning it with the

screws, and then push in and down to

lock in place.

Keep the HOBO LCD Logger Dry

The HOBO LCD logger is designed for a

non-condensing, non-corrosive

environment. Keep the logger dry. Some

of the external probes can be placed in

harsher environments; see External Probe

Specifications on page 13.

2.5 cm (1")

Loading...

Loading...