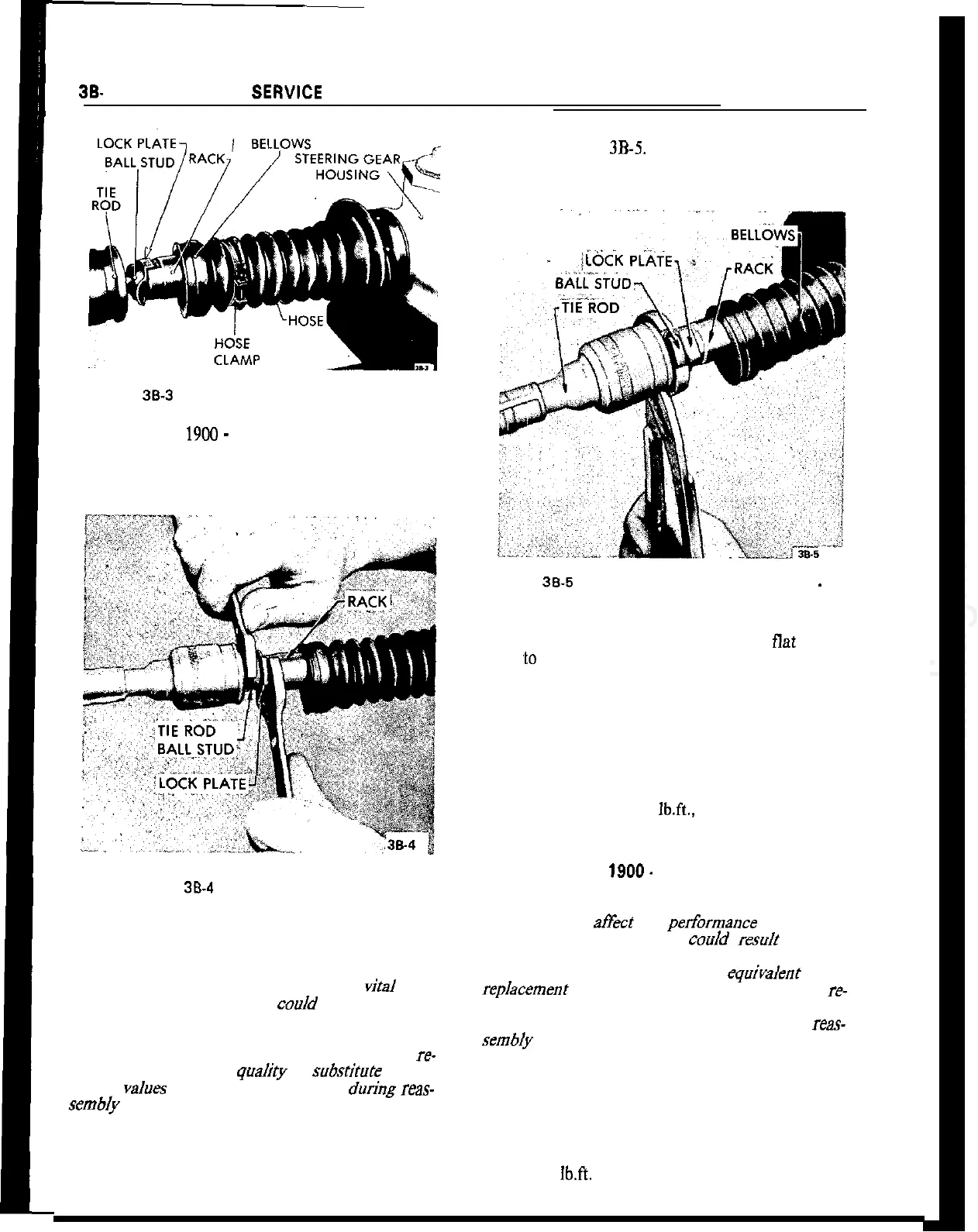

Figure 38-3 Bellows Removed From Tie Rod GT

5. On the Opel

1900

-

Manta, unscrew tie rod from

axial joint. It is important that rack be held secure

with open end wrench to prevent damage to rack

teeth.

38.

20 1973 OPEL SERWCE MANUAL

Figure 38.4 Removing Tie Rods. GT

Installation . GT

CAUTION:

Fasteners are important attaching parts in

that they could affect the performance of

vital

com-

ponents and systems, and/or coo/d result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part or lesser

quaJity

or sub.Mute design.

Torque

vaJues

must be used as specified

during

reas-

sembJy

to assure proper retention of these parts.

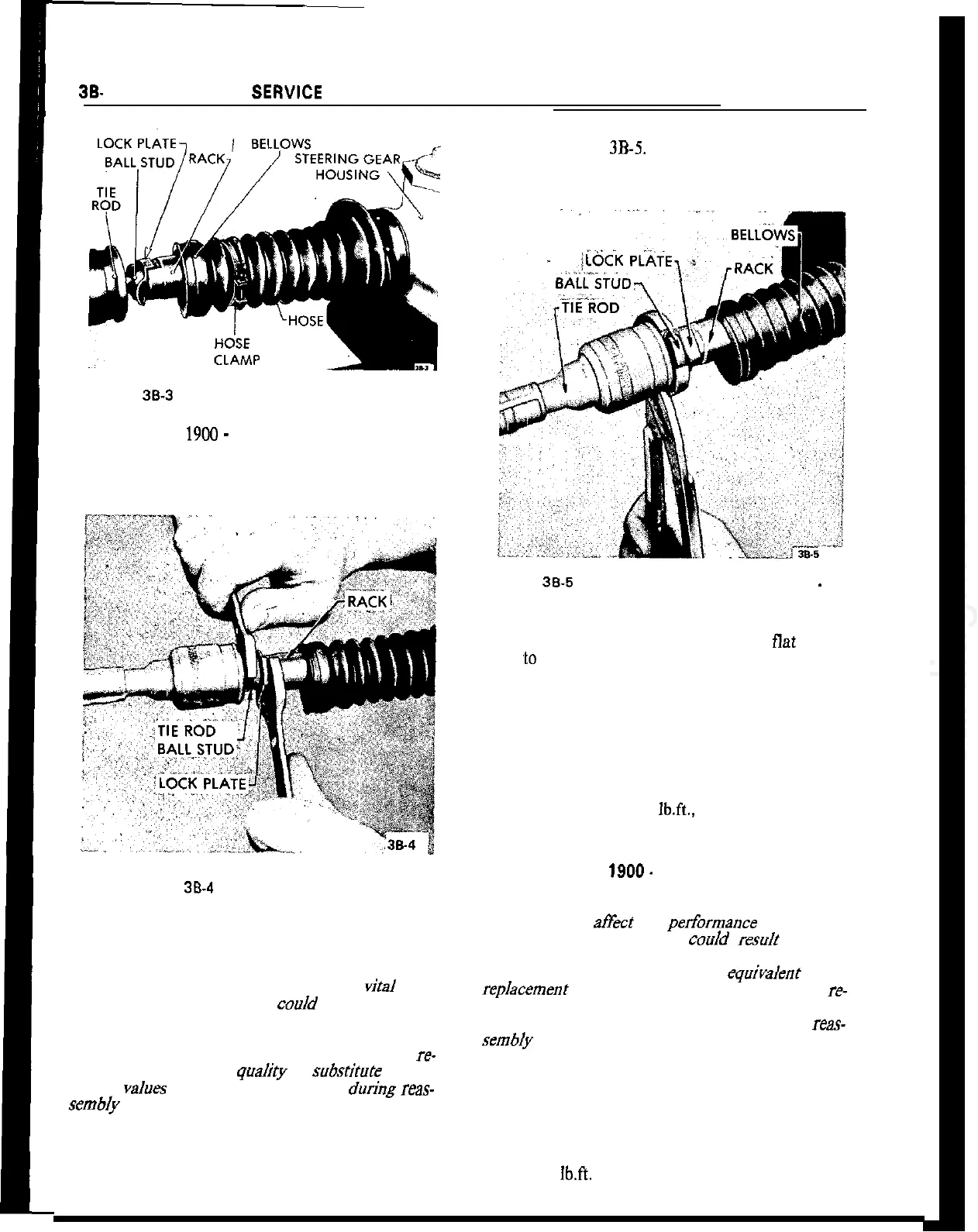

1. Install new lock plates onto tie rod ball studs and

screw ball studs into rack while holding bent tab of

lock plates against flat on rack. Torque ball studs 43

lb.ft. See Figure

3B-5.

It is important that rack be

held secure with open end wrench to prevent damage

to rack teeth.

Figure 38-5 Bending Lock Plate Over Ball Stud

-

GT

2. Bend round edges of lock plate over

flat

on ball

stud

‘to

lock ball stud in position.

3. Position rubber bellows and hose clamps over tie

rods and adjust clamp so that wire ends are pointing

in same direction as adjusting screw. Check that bel-

lows are not twisted and will compress and expand

properly.

4. Connect outer tie rod ball stud to steering arm,

torque castle nut to 29

lb.ft.,

and lock in position

with new cotter pin.

Installation Opel

1900.

Manta

CAUTION:

Fasteners are important attachingparts in

that they could

ah%

the

performance

of vital com-

ponents and systems, and/or

couJd

reslllt

in major

repair expense. They must be replaced with one of

the same part number or with an

equivalenr

part if

repJacement

becomes necessary. Do not use a re-

placement part of lesser quality or substitute design.

Torque valves must be used as specified during reas-

sembfy to assure proper retention of these parts.

1. Screw tie rod into axial joint.

2. Attach tie rod end to steering arm and torque nut

to 29 lb.ft. Install new cotter pin.

3. Adjust toe-in and then torque lock nut of both tie

rods to 47 lbft.

Loading...

Loading...