3E- 38

,1973

OPEL SERVICE MANUAL

ponents and systems, and/or could result in major

repair expense. They must be replaced with one or

the same part number or with

an

equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque

values

must be used as specified

during

reas-

sembly to assure proper retention of these parts.

On installation, make sure steering wheel spokes

point downwards and steering gear is in high point.

1. Carefully insert steering mast into universal joint

flange.

2. Loosely attach slide-off base attaching nuts at un-

derside of instrument panel.

3. Attach steering mast jacket at front of dash, using

a notched hex nut.

4. Torque nuts at slide-off base to II

lb.ft.

5. Tighten screw at steering mast clamp to 22

lb.ft.

6. Reconnect wires to directional signal switch and

ignition switch.

7. Reconnect battery.

REMOVAL AND INSTALLATION OF

STEERING WHEEL

This procedure may be performed with the steering

column assembly either removed or installed in the

car.

Removal

1.

Disconnect battery.

2. Pry off horn cap and remove wires from cap. See

Figure

3E-3.

3. Bend lockplate tabs down and take off steering

shaft nut and lockplate.

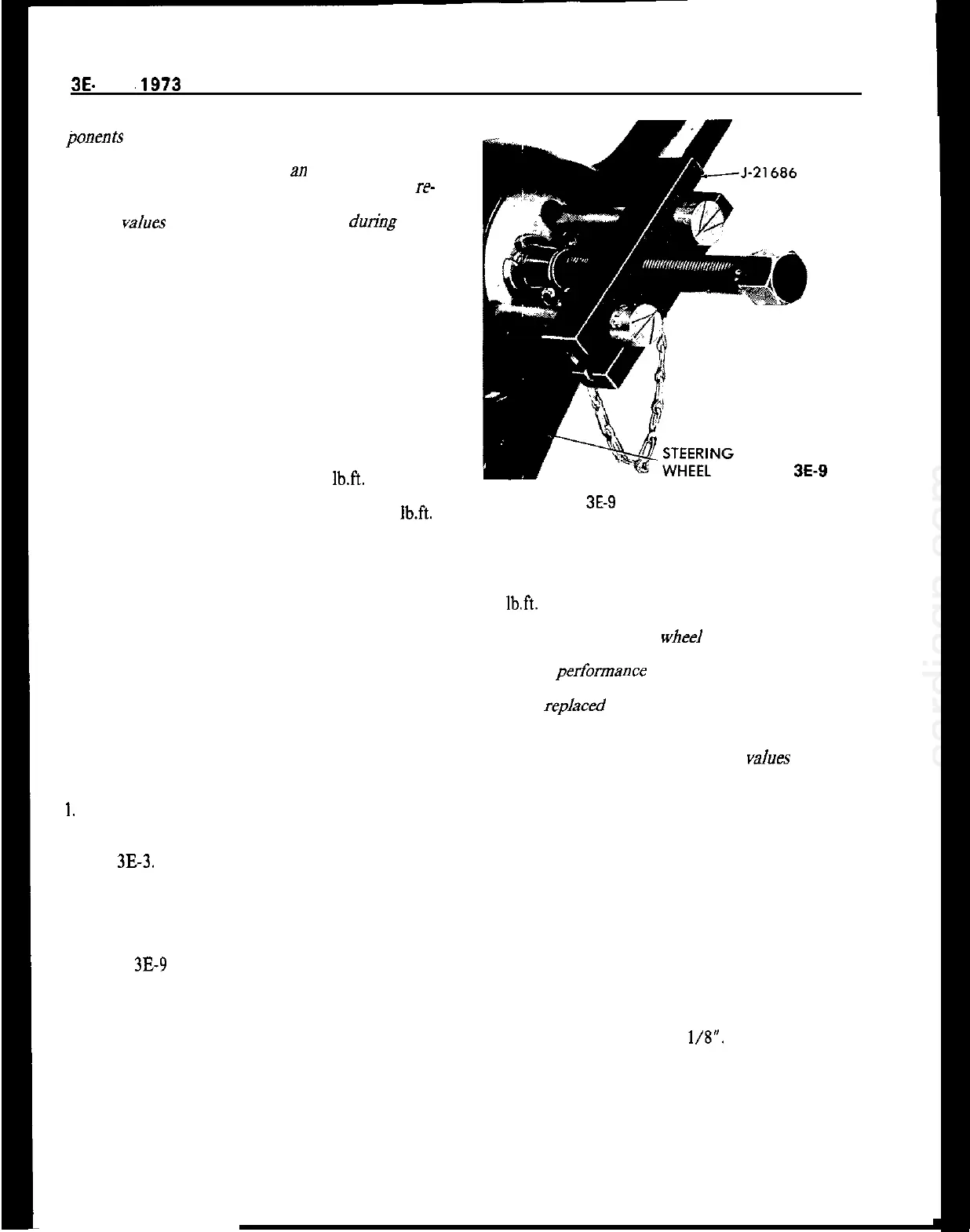

4. Install steering wheel remover J-21686 as shown

in Figure

3E-9

and pull off steering wheel.

Installation

1. Before installing steering wheel, lubricate return

pin and sliding area on directional signal switch re-

turn cams and horn contact ring.

2. Make sure that clamp bolt in steering shaft flange

is on top.

3. Make sure notch on steering shaft face is in hori-

zontal position.

Figure

3E-9

Removing Steering Wheel

4. With the steering wheel centered, place the steer-

ing wheel onto the steering shaft.

5. Install steering wheel lockplate and nut. Torque to

11

lb.ft.

CAUTION:

This steering

wheeI

to steering shaft fas-

tener is an important attaching part in that it could

affect the performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be

repked

with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque

values

must be

used as specified during reassembly to assure proper

retention of this part.

6. Bend lockplate tabs up, connect horn cap wires

and replace cable and cap.

7. Reconnect battery.

REMOVAL AND REPLACEMENT OF HORN

CONTACT RING

1. Remove steering wheel.

2. Cut off defective contact ring at wire.

3. Strip wire approximately

l/8”.

4. Install new part and solder connection with resin

core solder.

5. Lubricate contact ring with lubriplate, or equiva-

lent.

6. Reinstall steering wheel.

Loading...

Loading...