RECESSES VERTICAL FOR

REMOVAL OF LEFT ROW OF

CYLINDER HEAD BOLTS

6A-16

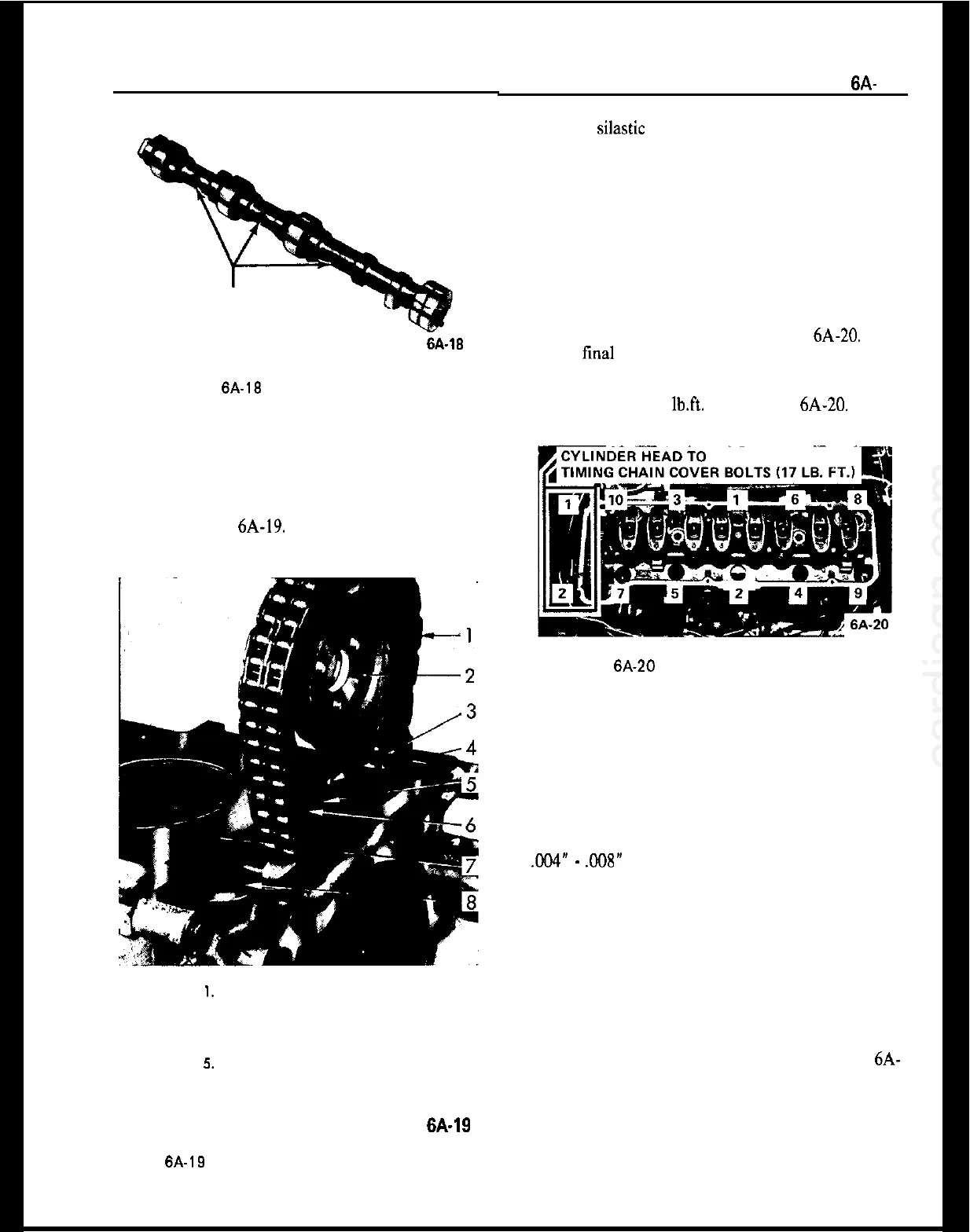

Figure 6A-18 Recesses in Camshaft

2. Clean piston tops and combustion chambers.

Thoroughly clean all gasket surfaces on the cylinder

block and cylinder head.

3. Lightly lubricate cylinder walls with engine oil.

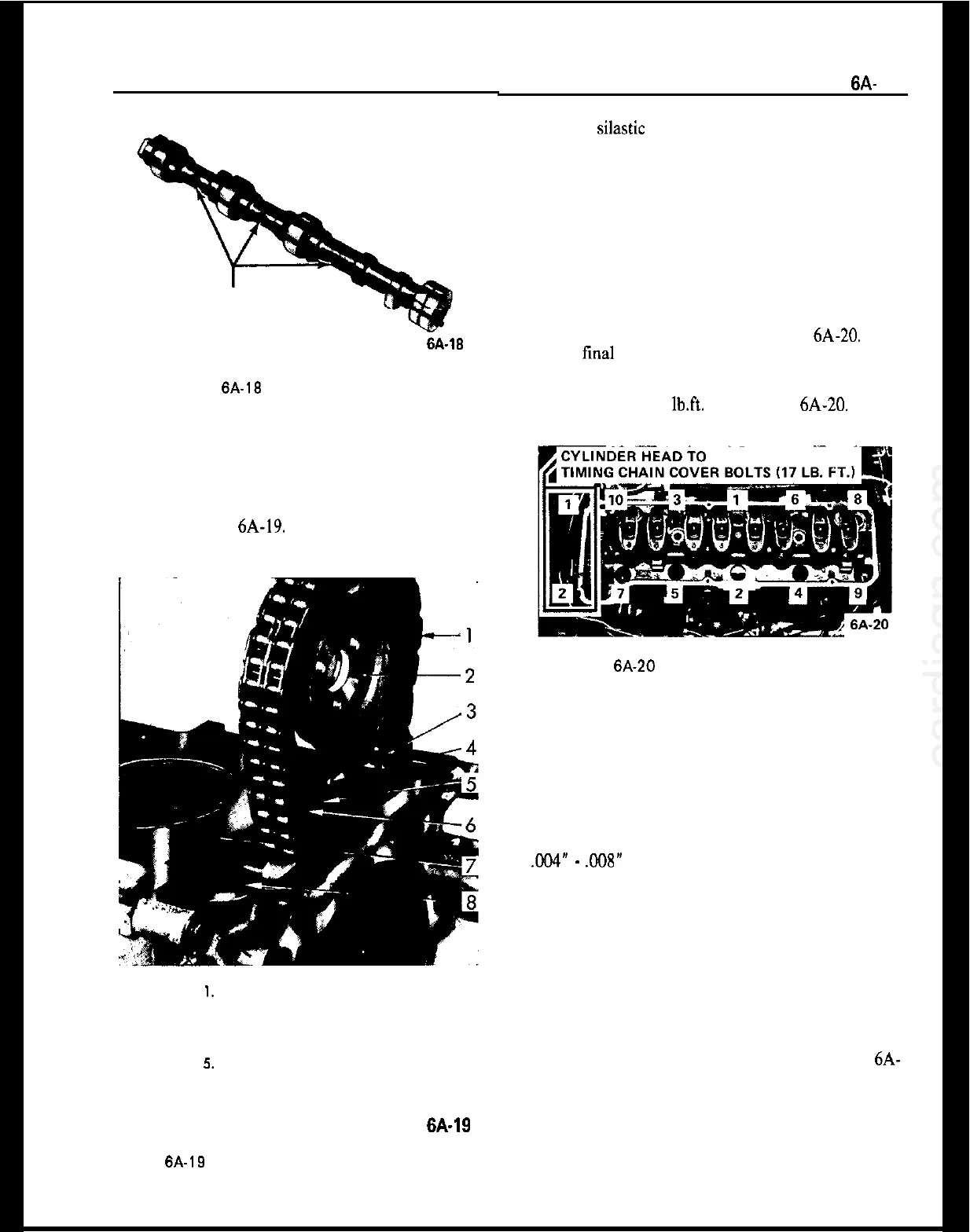

Install coolant passage rubber gasket ring in timing

case. See Figure 6A-19.

I. TIMING CHAIN

2. CAMSHAFT SPROCKET

3. SPROCKET TIMING MARK

4. TIMING CASE

5.

SUPPORT TIMING MARK

6. SUPPORT

7. CYLINDER BLOCK

6. RUBBER GASKET RING

6A-19

Figure 6A-19 Coolant Passage Rubber Gasket Ring in

Timing Case

ENGINE MECHANICAL AND MOUNTS

6A-

13

4. Apply silastic sealer or equivalent to both sides of

the cylinder head gasket where the gasket mates with

the timing chain cover, place new cylinder head gas-

ket onto cylinder block.

5. Install cylinder head. Be careful to place head

squarely over guide pins.

Rotate camshaft so that recesses are in vertical posi-

tion to allow installation of left row of bolts.

6. Install 10 head bolts. Tighten the bolts a little at

a time in the sequence shown in Figure 6A-20. Give

bolts a final torque in the same sequence. Torque to

72 lb. ft. (cylinder head cold). Use same procedure

for cylinder head to timing chain cover bolts with

final torque at 17

lb.ft.

See Figure 6A-20. These

torques apply to lightly oiled threads.

Figure 6A-20 Cylinder Head Bolt Tightening

sequence

7. Slide camshaft sprocket with assembled chain onto

camshaft and guide pin and fasten with bolts. Install

nylon adjusting screw. After sprocket has been at-

tached to camshaft, recheck alignment to see that

chain has not slipped. Close front access hole.

8. Check camshaft end clearance between cover and

nylon screw with feeler gauge. Clearance should be

.004”

-

.008”

Excess clearance can be eliminated by

carefully readjusting cover with a suitable drift.

Reconditioning Valves and Guides

1. Remove cylinder head. Place on clean surface.

Place head on bench supported at each end by a

block of wood to prevent damage to valves.

2. Using suitable spring compressor, such as J-8062,

compress valve spring and remove cap retainers. Re-

lease tool and remove spring and cap. See Figure 6A-

21.

3. Remove valves. Place valves in numerical order so

that they can be reinstalled in original location.

4. Remove all carbon from combustion chambers,

piston heads, and valves. When using scrapers or

Loading...

Loading...