6G- 66 1973 OPEL SERVICE MANUAL

6. Check compression of each cylinder. Repeat

compression check and record highest reading ob-

tained on each cylinder during the two pressure

checks.

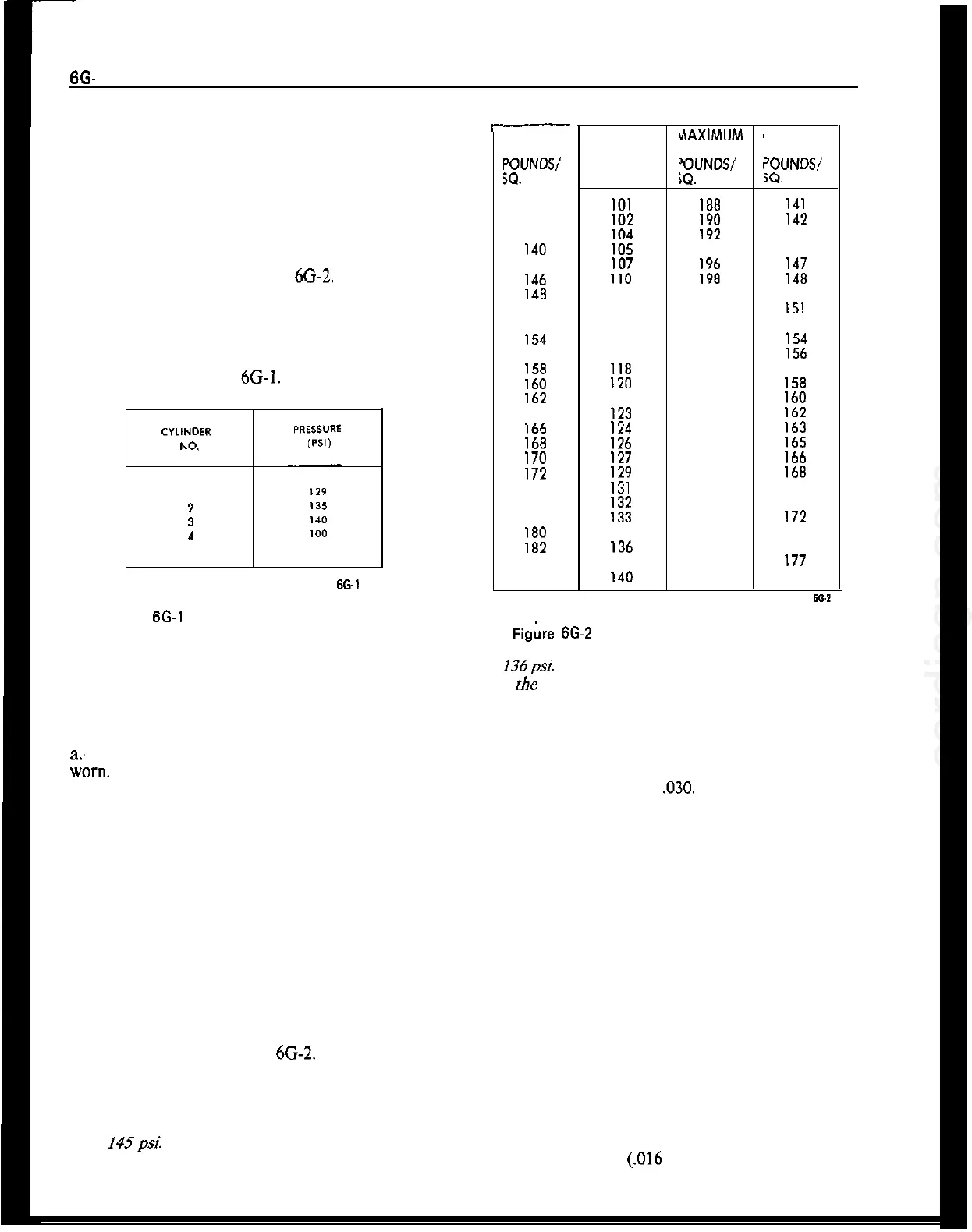

The recorded compression pressures are to be con-

sidered normal if the lowest reading cylinder is more

than 75 percent of the highest reading cylinder. See

the following example and the “Compression Pres-

sure Limit Chart.” See Figure

6G-2.

Seventy-five percent of 140 (highest) is 105. Thus,

cylinder No. 4 is less than 75 percent of No. 3. This

condition, accompanied by low speed missing, indi-

cates an improperly seated valve or worn or broken

piston ring. See Figure 6G-1.

2

3

I

SO-1

Figure 6G-1 Example of Compression Check

7. If one or more cylinders read low, inject about a

tablespoon of engine oil on top of pistons in low

reading cylinders through spark plug port. Repeat

compression check on these cylinders.

a:

If compression improves considerably, rings are

lV0*tl.

b. If compression does not improve, valves are stick-

ing or seating poorly.

c. If two adjacent cylinders indicate low compression

and injecting oil does not increase compression, the

cause may be the head gasket leaking between the

cylinders. Engine coolant and/or oil in cylinders

could result from this defect.

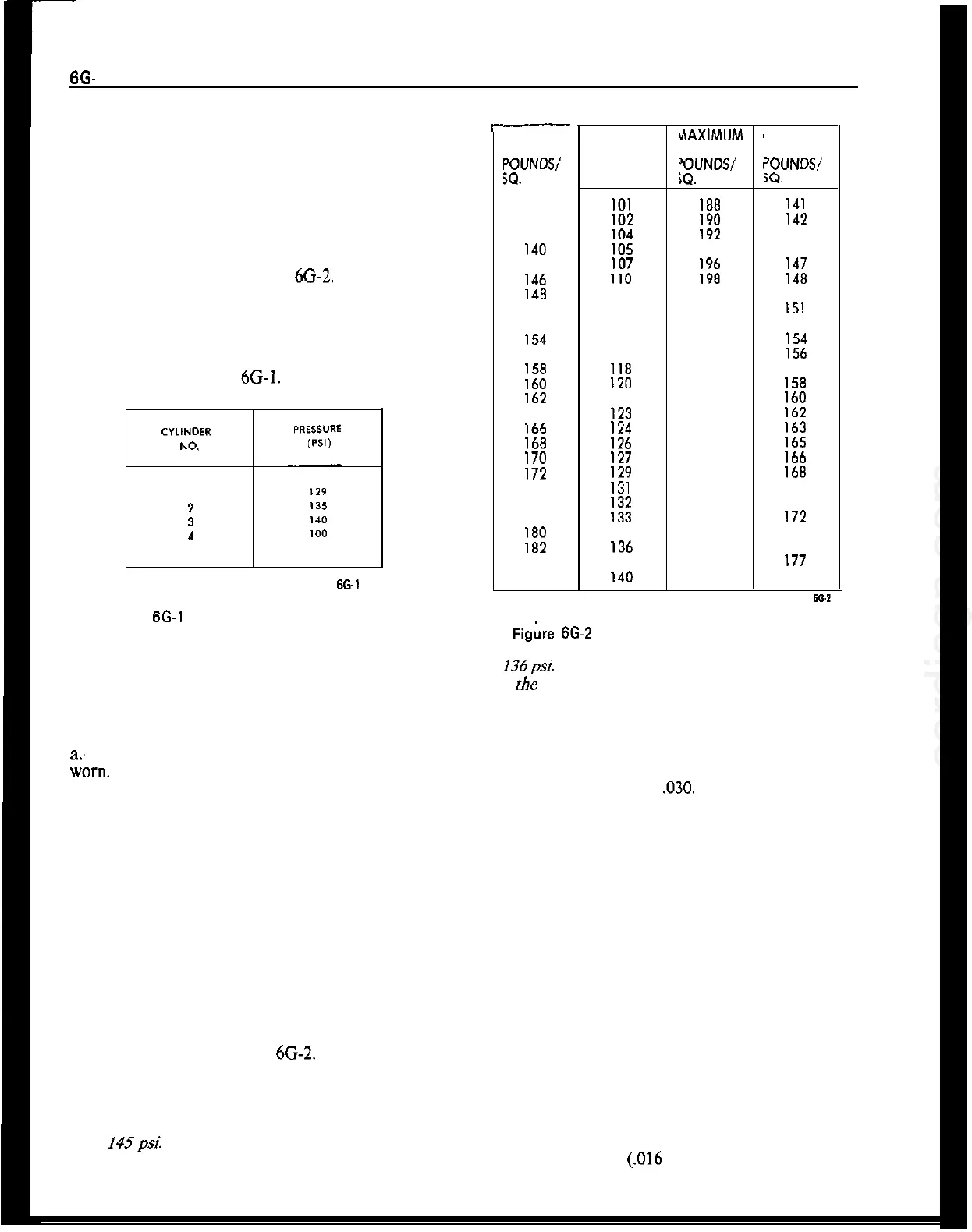

Compression Pressure Limit Chart

This chart may be used when checking cylinder com-

pression pressures. It has been calculated so that the

lowest reading number is 75 percent of the highest

reading number. See Figure 6G-2.

EXAMPLE:

After checking the compression pressures

in all cylinders, it was found that the highest pressure

obtained was 182 psi The lowest pressure reading

was

145psi.

By locating 182 in the maximum col-

umn, it is seen that the minimum allowable pressure

r

-.__

MAXIMUM

PRESSURE

POIJNW

W.

INCH

--

134

136

138

140

142

146

148

150

152

154

156

158

160

lb2

164

166

168

170

172

174

176

178

180

182

184

186

MINIMUM

PRESSURE

POUNDS/

SQ. INCH

HAXIMUM

‘RESSURE

‘OUNW

iQ. INCH

MINIMUM

PRESSURE

“OUNW

X?.

INCH

101 188

I41

I02

190

142

104 192 144

105 194 145

107 196 147

II0

198 148

Ill 200 150

113

202

151

114

204

153

115

206

154

117

208

156

118

210

157

120

212

158

121

214

160

123

216

162

124

218

163

126

220

165

127

222

166

129

224

168

131

226

169

132

228

171

133

230

172

135

232

174

136

234

175

138 236

177

140 238

178

Figire

6G.2 Compression Pressure Limit Chart

is 136psi. Since the lowest reading obtained was 145

psi, the car is within limits and the compression is

considered satisfactory.

Spark Plugs

1. Inspect, clean and regap or replace spark plugs as

required. Correct gap is

,030.

2. Install spark plugs. Tighten to 30 lb.ft.

Secondary Ignition System

1. Inspect ignition cables for broken, swollen or

deteriorated insulation.

2. Check terminal ends and condition of rubber

boots. Replace as required.

3. Inspect the condition of the distributor cap and

rotor.

4. Clean the ignition coil and inspect for cracks or

carbon paths which could cause high voltage leak-

age.

Distributor Contact Points

1. Inspect distributor contact points and replace or

adjust as necessary

(.016

gap).

Loading...

Loading...